A preparation method of carbonized modified red mud ceramsite adsorbent and its regeneration method and application

A technology of red clay ceramsite and adsorbent, applied in chemical instruments and methods, separation methods, filter regeneration, etc., can solve problems such as insufficient adsorption performance of red clay ceramsite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

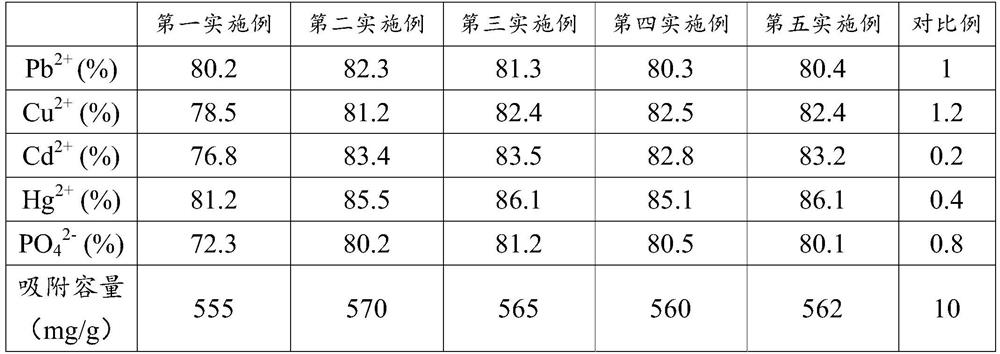

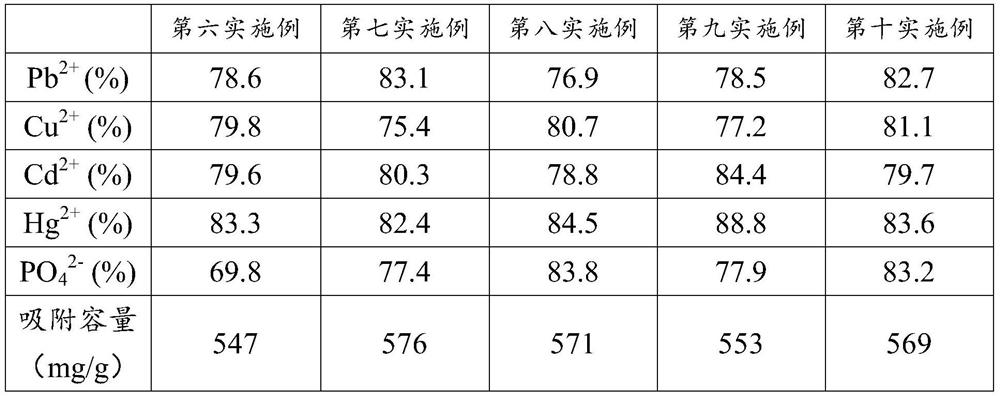

Examples

no. 1 example

[0025] A kind of preparation of carbonized modified red mud ceramsite adsorbent comprises the following steps:

[0026] (1) Prepare Bayer process red mud into ceramsite with a particle size of about 1-1.5 cm, place it in an oven, and dry it at 100°C for 12 hours;

[0027] (2) Put the dried red mud ceramsite in a carbonization kettle, and use carbon dioxide with a purity of 99.9% as carbonization gas. The pressure in the carbonization kettle is 1 MPa, the humidity is 30%, the temperature is 50 ° C, and the time is 2 hours; after the carbonization is completed Then dry at 100°C for 12 hours to obtain modified red mud ceramsite.

no. 2 example

[0029] A kind of preparation of carbonized modified red mud ceramsite adsorbent comprises the following steps:

[0030] (1) Prepare Bayer red mud into ceramsite with a particle size of about 1-1.5 cm, place it in an oven, and dry it at 120 ° C for 10 h;

[0031] (2) Place the dried red mud ceramsite in a carbonization kettle, and use carbon dioxide with a purity of 99.9% as carbonization gas. The pressure in the carbonization kettle is 1MPa, the humidity is 60%, the temperature is 100°C, and the time is 2h; after the carbonization is completed Then dry at 120°C for 10 hours to obtain modified red mud ceramsite.

no. 3 example

[0033] A kind of preparation of carbonized modified red mud ceramsite adsorbent comprises the following steps:

[0034] (1) Prepare Bayer process red mud into ceramsite with a particle size of about 1-1.5 cm, place it in an oven, and dry it at 110°C for 12 hours;

[0035] (2) Place the dried red mud ceramsite in a carbonization kettle, and use carbon dioxide with a purity of 99.9% as carbonization gas. The pressure in the carbonization kettle is 2MPa, humidity is 60%, temperature is 50°C, and time is 4h; after carbonization is completed Then dry at 110°C for 12 hours to obtain modified red mud ceramsite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com