Preparation method, regeneration method and application of carbonized modified red mud ceramsite adsorbent

A technology of red mud ceramsite and adsorbent, which is applied in the direction of chemical instruments and methods, separation methods, filter regeneration, etc., can solve the problems of insufficient adsorption performance of red mud ceramsite, achieve good carbonization effect, enhance adsorption performance, reduce The effect of sodium-alkali content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

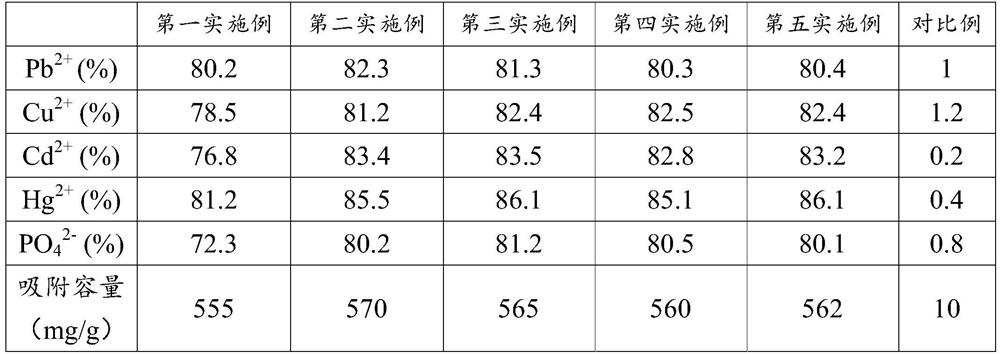

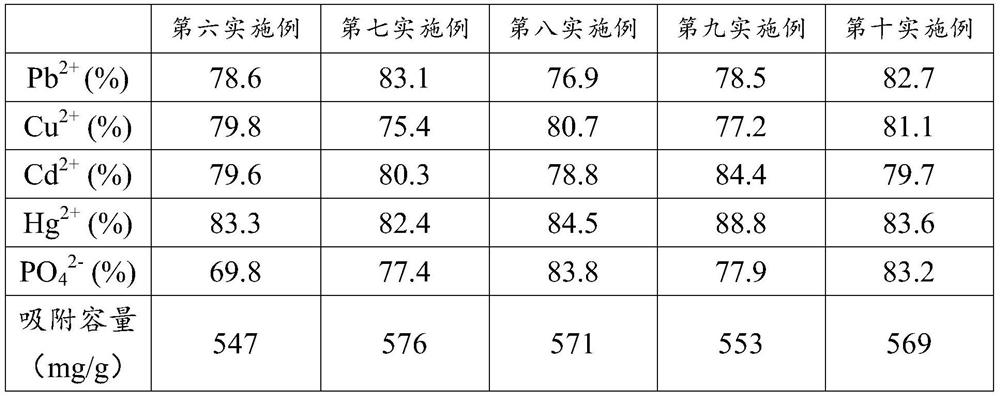

Examples

no. 1 example

[0025] A kind of preparation of carbonized modified red mud ceramsite adsorbent comprises the following steps:

[0026] (1) Prepare Bayer process red mud into ceramsite with a particle size of about 1-1.5 cm, place it in an oven, and dry it at 100°C for 12 hours;

[0027] (2) Put the dried red mud ceramsite in a carbonization kettle, and use carbon dioxide with a purity of 99.9% as carbonization gas. The pressure in the carbonization kettle is 1 MPa, the humidity is 30%, the temperature is 50 ° C, and the time is 2 hours; after the carbonization is completed Then dry at 100°C for 12 hours to obtain modified red mud ceramsite.

no. 2 example

[0029] A kind of preparation of carbonized modified red mud ceramsite adsorbent comprises the following steps:

[0030] (1) Prepare Bayer red mud into ceramsite with a particle size of about 1-1.5 cm, place it in an oven, and dry it at 120 ° C for 10 h;

[0031] (2) Place the dried red mud ceramsite in a carbonization kettle, and use carbon dioxide with a purity of 99.9% as carbonization gas. The pressure in the carbonization kettle is 1MPa, the humidity is 60%, the temperature is 100°C, and the time is 2h; after the carbonization is completed Then dry at 120°C for 10 hours to obtain modified red mud ceramsite.

no. 3 example

[0033] A kind of preparation of carbonized modified red mud ceramsite adsorbent comprises the following steps:

[0034] (1) Prepare Bayer process red mud into ceramsite with a particle size of about 1-1.5 cm, place it in an oven, and dry it at 110°C for 12 hours;

[0035] (2) Place the dried red mud ceramsite in a carbonization kettle, and use carbon dioxide with a purity of 99.9% as the carbonization gas. The pressure in the carbonization kettle is 2MPa, the humidity is 60%, the temperature is 50°C, and the time is 4h; after the carbonization is completed Then dry at 110°C for 12 hours to obtain modified red mud ceramsite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com