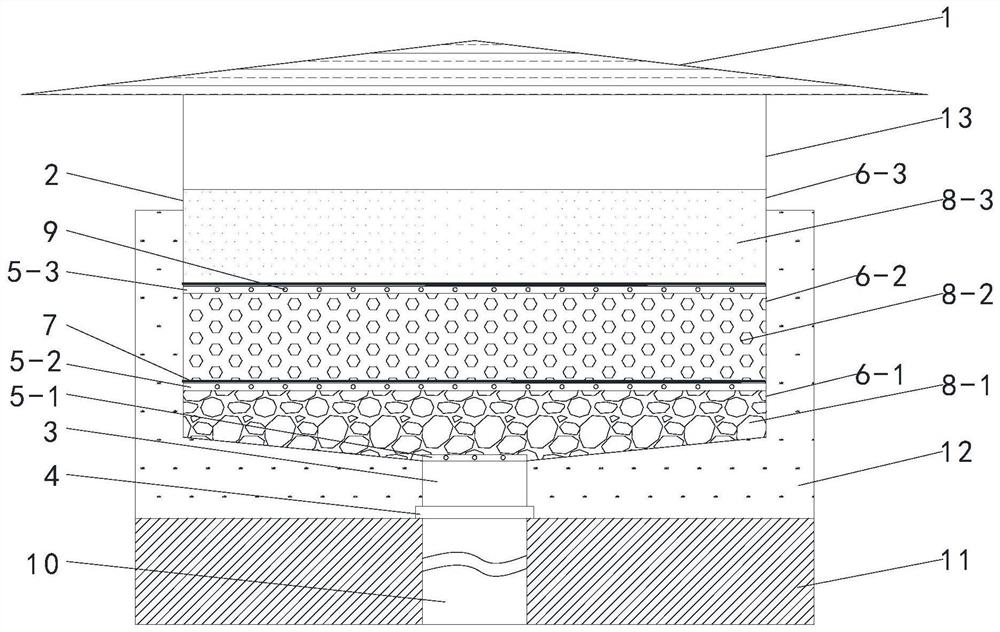

Methane oxidation device, mounting method and oxidation method

A methane oxidation and shell technology, applied in chemical instruments and methods, methane capture, separation methods, etc., can solve the problem of neglecting the efficient collection and drainage of landfill gas, the lack of device support for the methane oxidation technology system, and it is difficult to increase The structural unit of methane oxide layer and other problems can overcome the fracture of methane oxide layer and gas "short circuit, facilitate monitoring and evaluation, and ensure safety and long-term performance".

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

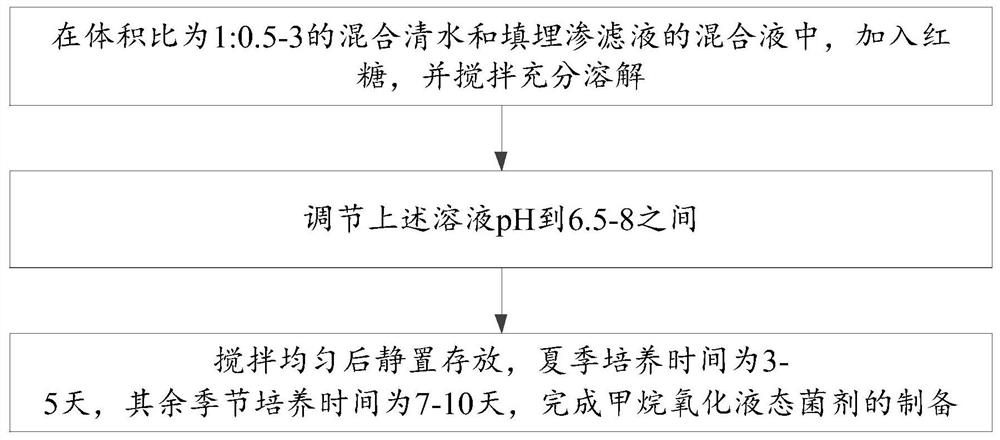

[0074] Such as image 3 Shown, the preparation method of methane oxidation liquid bacterial agent of the present invention comprises:

[0075] S31, in the mixed solution of mixed clear water and landfill leachate with a volume ratio of 1:0.5-3, based on the total water volume, add 5%-10% commercially available brown sugar, and stir to fully dissolve;

[0076] S32, adjusting the pH of the above solution to between 6.5-8;

[0077] S32. Stir evenly and leave it to stand for storage. The cultivation time in summer is 3-5 days, and the cultivation time in other seasons is 7-10 days, and the preparation of the methane oxidation liquid bacterial agent is completed; wherein, the methane oxidation liquid bacterial agent should be prepared as needed. The longest storage time is not longer than 3 months.

[0078] Such as Figure 4 Shown, the present invention also provides a kind of oxidation method of methane oxidation unit, comprising:

[0079] S41. Connect the methane oxidation de...

Embodiment

[0083] A domestic waste landfill in southern my country covers a total area of about 40,000 m 2 , since the simple closure of the site in 2012, the landfilled storage capacity is about 570,000 m 3 . At present, the methane concentration inside the landfill is about 26%, which is lower than the threshold of self-sustaining combustion, and the remaining landfill gas production is expected to be as high as 5.3 million m 3 , a huge potential for greenhouse gas emissions. Based on this, the project decided to adopt the method of closure + methane oxidation to control the pollution of the landfill. According to the characteristics of this landfill, more than 30 gas guide shafts have been set up in the project, which are used together with the above-mentioned methane oxidation device, and the distance between the gas guide shafts is 50 meters.

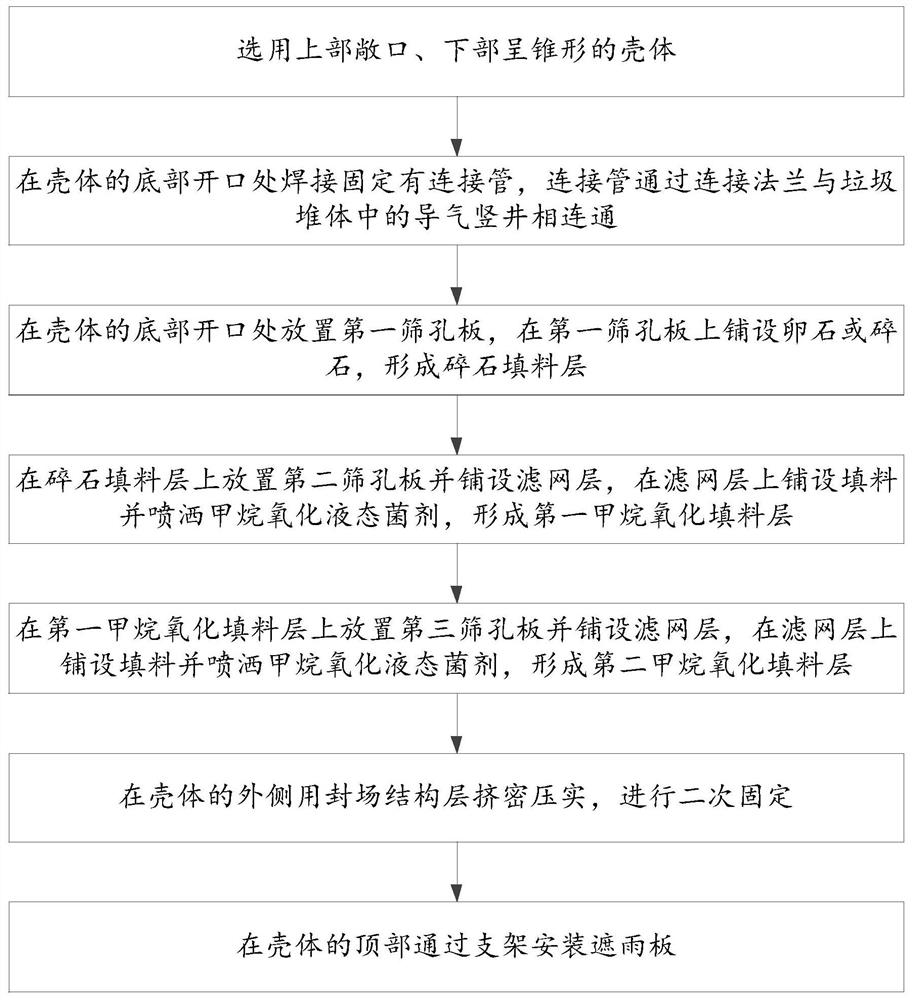

[0084] In this embodiment, the method for installing and using the methane oxidation device includes the following steps:

[0085] S1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com