Vacuum pump

A technology of vacuum pumps and turbomolecular pumps, applied in pumps, pump components, axial flow pumps, etc., can solve problems such as narrowing of flow paths, degraded exhaust performance, and decreased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

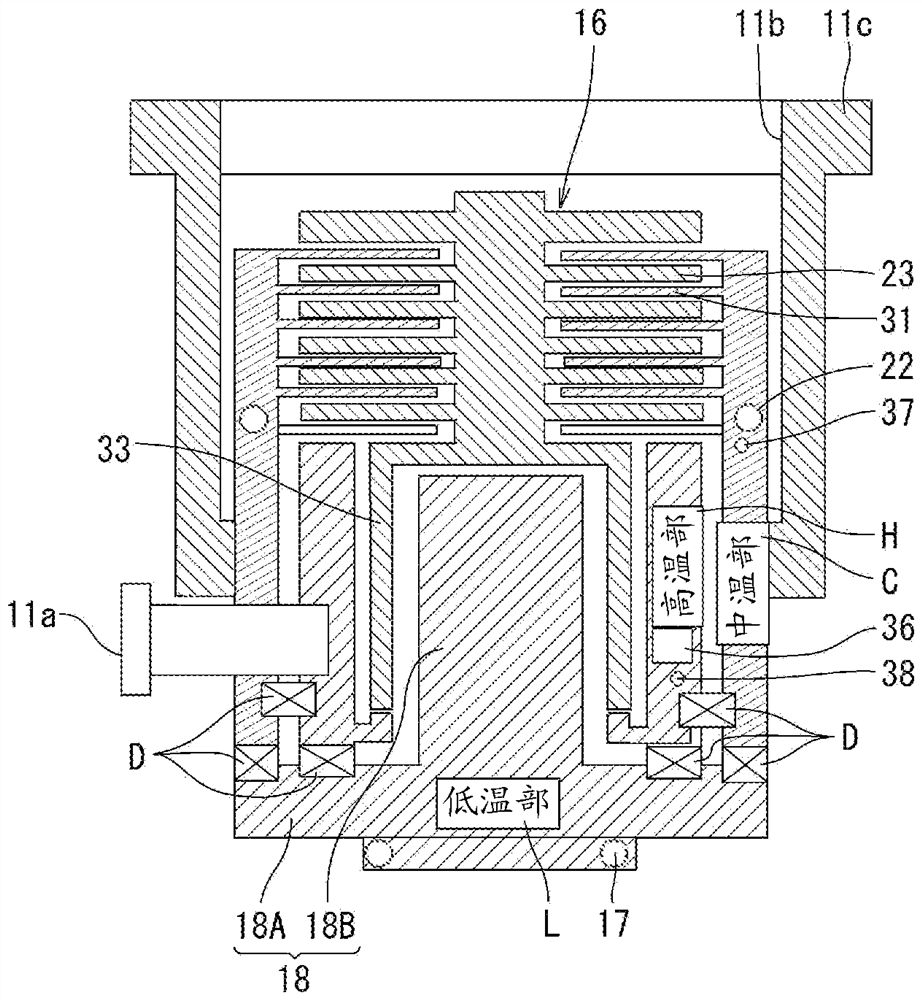

[0045] figure 1 It is a longitudinal sectional view of a vacuum pump 10 shown as an embodiment of the present invention, figure 2 yes figure 1 An enlarged partial cross-sectional view of vacuum pump 10 is shown. figure 1 and figure 2 Herein, the vacuum pump 10 is a compound pump including a turbomolecular pump mechanism PA and a screw groove pump mechanism PB housed in a substantially cylindrical casing 11 as an exhaust function part 12 .

[0046] The vacuum pump 10 has a casing 11, a rotor 15 having a rotor shaft 14 rotatably supported in the casing 11, an electric motor 16 for rotating the rotor shaft 14, and a stator column 18B for accommodating a part of the rotor shaft 14 and the electric motor 16. The base of 18 et al.

[0047] The case 11 is formed in a bottomed cylindrical shape. The casing 11 functions as a stator of the turbomolecular pump mechanism PA, and has a tubular portion 11A and a water-cooling spacer 11B. Moreover, the heater spacer 11C of circular t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com