Lubricating oil composition, method for producing lubricating oil composition, and continuously variable transmission

A technology of lubricating oil composition and synthetic oil, which is applied in the directions of lubricating composition, petroleum industry, base material, etc., can solve problems such as difficult to take into account

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0113] (Preparation of Lubricating Oil Compositions of Example 1 and Comparative Examples 1 to 6)

[0114] Lubricating oil compositions were produced by compounding according to the formulations shown in Table 1 below. Table 1 shows the evaluation results of properties and performances measured by the above-mentioned method for each lubricating oil composition obtained.

[0115] [Table 1]

[0116]

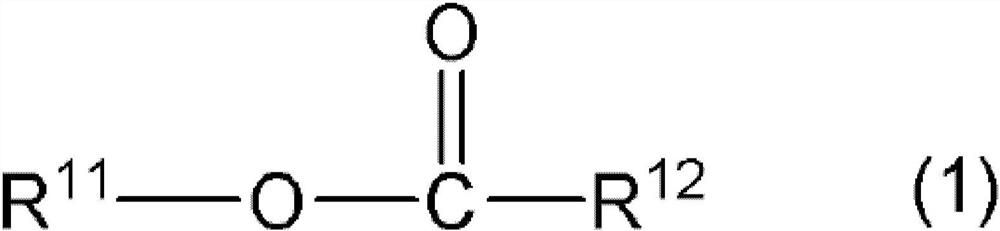

[0117] The naphthene-based synthetic oils, longifolene, and ester-based synthetic oils described in Table 1 used in this example were represented by the following chemical formulae.

[0118] [chemical 9]

[0119]

[0120] Naphthene-based synthetic oil: R in the general formula (2) shown in the above chemical formula 21 and R 23 is methyl, R 22 is methylene, X 21 and x 22 For bicyclo[2.2.1]heptane ring, p 21 is 2, p 22 1 naphthene-based synthetic oil.

[0121] · Longifolene mixture: (1S, 3aR, 4S, 8aS)-4,8,8-trimethyl-9-methylene-decahydro-1,4-methyl azulene (92 mass %...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| Brookfield viscosity | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com