Continuous microwave drying method for accumulator plate

A microwave drying and storage battery technology, applied in the direction of lead-acid battery electrodes, drying solid materials, progressive dryers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

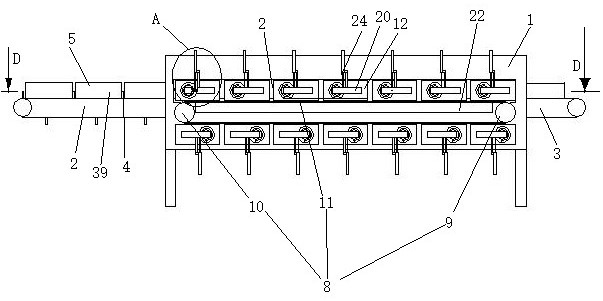

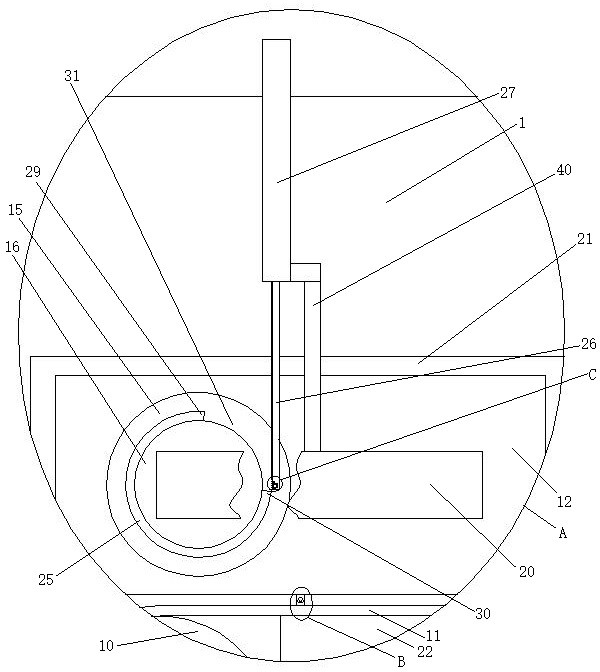

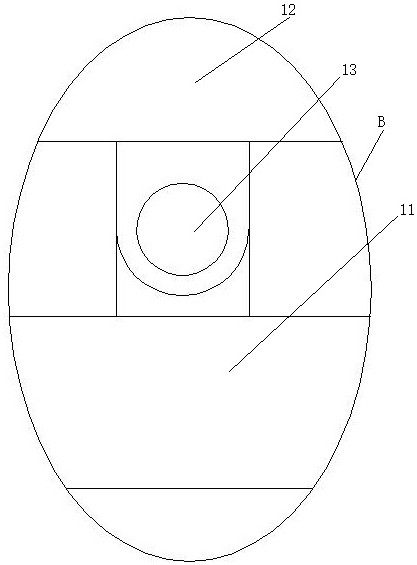

[0028] see Figure 1 to Figure 7 , a method for continuous microwave drying of battery pole plates, the battery pole plates are continuously passed through a microwave heating kiln through a conveying mechanism, and the battery pole plates are heated and dried by microwaves when passing through the microwave heating kiln. This method adopts but is not limited to Figures 1 to 7 The microwave drying machine shown in the figure is completed, and the microwave drying machine includes a microwave heating kiln 1, a feeding conveyor belt 2, a feeding conveyor belt 3, and two sides clamping the thickness direction of the battery plate to transport the battery plate from the feeding Clamping plate transfer mechanism with belt transfer to the unloading conveyor belt. The feeding conveyor belt is provided with several positioning block pairs distributed along t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com