Hydraulic oil tank

A technology of hydraulic oil tank and oil chamber, applied in the field of hydraulic system, can solve the problems of poor performance, inability to greatly reduce the hydraulic oil temperature of the oil chamber, and the increase of the hydraulic oil temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

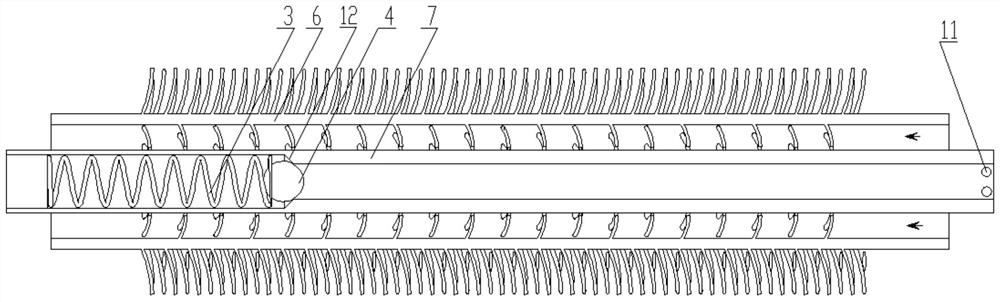

[0024] A hydraulic tank, such as figure 1 and figure 2 As shown, it includes a low-temperature oil chamber 2 and a high-temperature oil chamber 10. The oil supply port of the low-temperature oil chamber 2 is connected to the oil supply pipeline 1 and the pump 5. An on-off valve is arranged on the oil supply pipeline 1. The oil return of the high-temperature oil chamber 10 The port is connected to the oil return pipeline 1, and the low-temperature oil chamber 2 is connected to the high-temperature oil chamber 10 through a heat exchange tube. A fan is installed on the side of the heat exchange tube, and the wind introduced by the fan is used as the cooling medium of the heat exchange tube; The pipe is used to connect the low-temperature oil chamber 2 and the high-temperature oil chamber 10. An inner pipe is arranged axially in the casing. Within the allowable pressure, the inner pipe is a non-conductive structure, and the gap between the outer wall of the inner pipe and the inn...

Embodiment 2

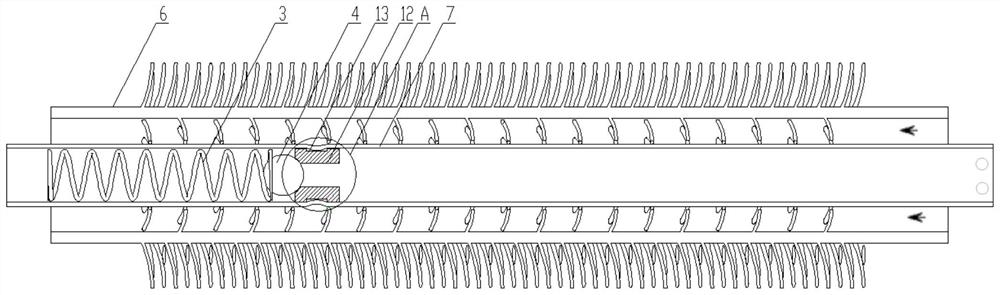

[0034] A hydraulic tank, such as figure 1 , image 3 and Figure 4 As shown, it includes a low-temperature oil chamber 2 and a high-temperature oil chamber 10. The oil supply port of the low-temperature oil chamber 2 is connected to the oil supply pipeline 1 and the pump 5. An on-off valve is arranged on the oil supply pipeline 1. The oil return of the high-temperature oil chamber 10 The port is connected to the oil return pipeline 1, and the low-temperature oil chamber 2 is connected to the high-temperature oil chamber 10 through a heat exchange tube. A fan is installed on the side of the heat exchange tube, and the wind introduced by the fan is used as the cooling medium of the heat exchange tube; The pipe is used to connect the low-temperature oil chamber 2 and the high-temperature oil chamber 10. An inner pipe is arranged axially in the casing. Within the allowable pressure, the inner pipe is a non-conductive structure, and the gap between the outer wall of the inner pipe...

Embodiment 3

[0044] A hydraulic oil tank. Referring to Embodiment 1, the difference between it and Embodiment 1 is that the gap between the outer wall of the inner tube A of the first heat exchange tube and the inner ring of the casing A is 1 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com