Tunnel periphery hole rock drilling method and stepped rock drilling machine

A drilling method and rock drill technology, which are applied to drill pipes, drill pipes, drilling equipment, etc., can solve the problems of not being able to exit smoothly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

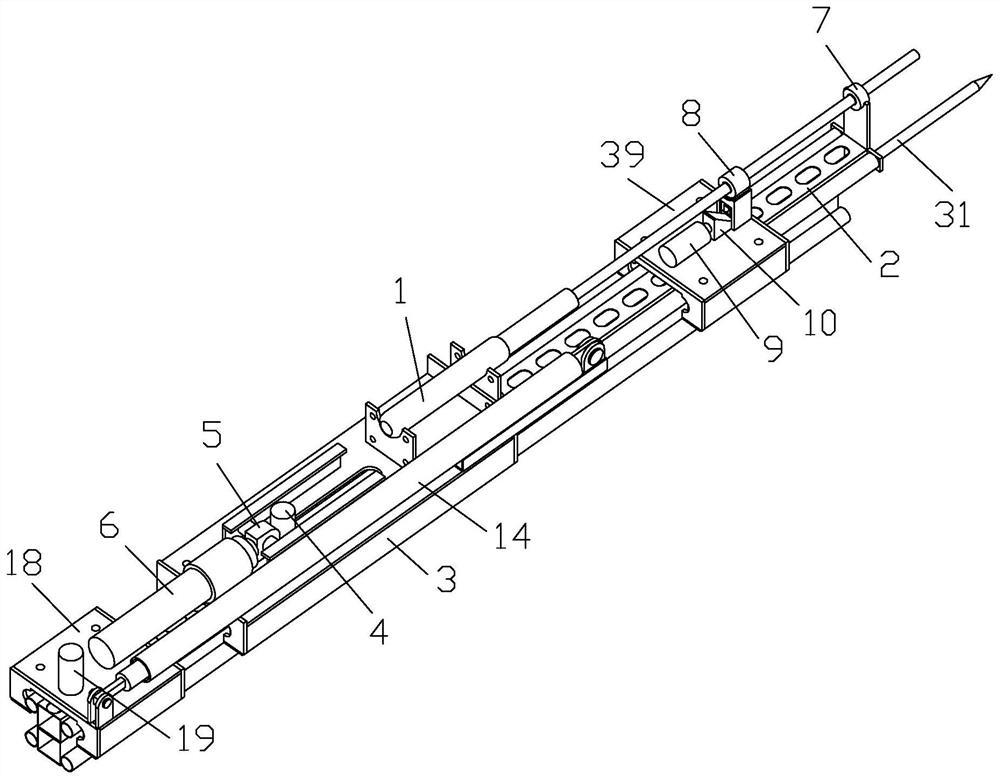

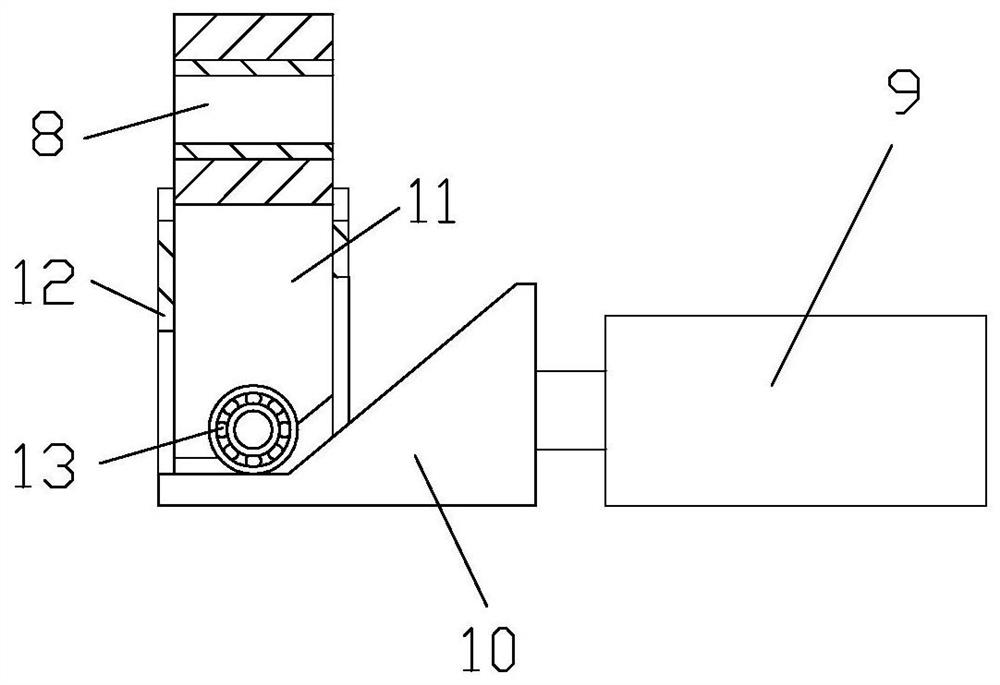

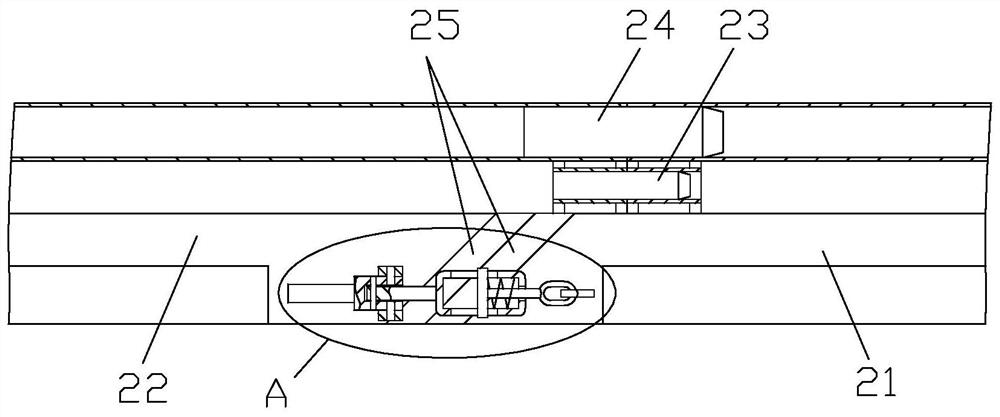

[0024] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , a stepping rock drill with a drill back device, including a rock drilling main engine 1, a guide rail 2, a drilling rig carrying slide 3, an air leg 14 and an air leg carrying slide 18, and a second A locking device; the drill carrying slide 3 is also provided with a drill retracting device; the drill retracting device includes a locking slider 5 and a drive mechanism 6 with a reciprocating movement output movement, and the drive mechanism 6 is connected to the drill carrying slide 3 and the locking slider 5, the locking slider 5 can only move longitudinally on the drilling rig bearing slide 3; the first locking device is arranged between the locking slider 5 and the guide rail 2 ; The air leg 14 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com