Steel structure and mounting method thereof

An installation method and technology of steel structure, applied in the direction of structural elements, building components, building structure, etc., can solve the problems of deformation of the top beam and bottom beam of the steel structure, affecting the construction effect of the building structure strength, etc., so as to avoid deformation problems and ensure Relative stability, sliding stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

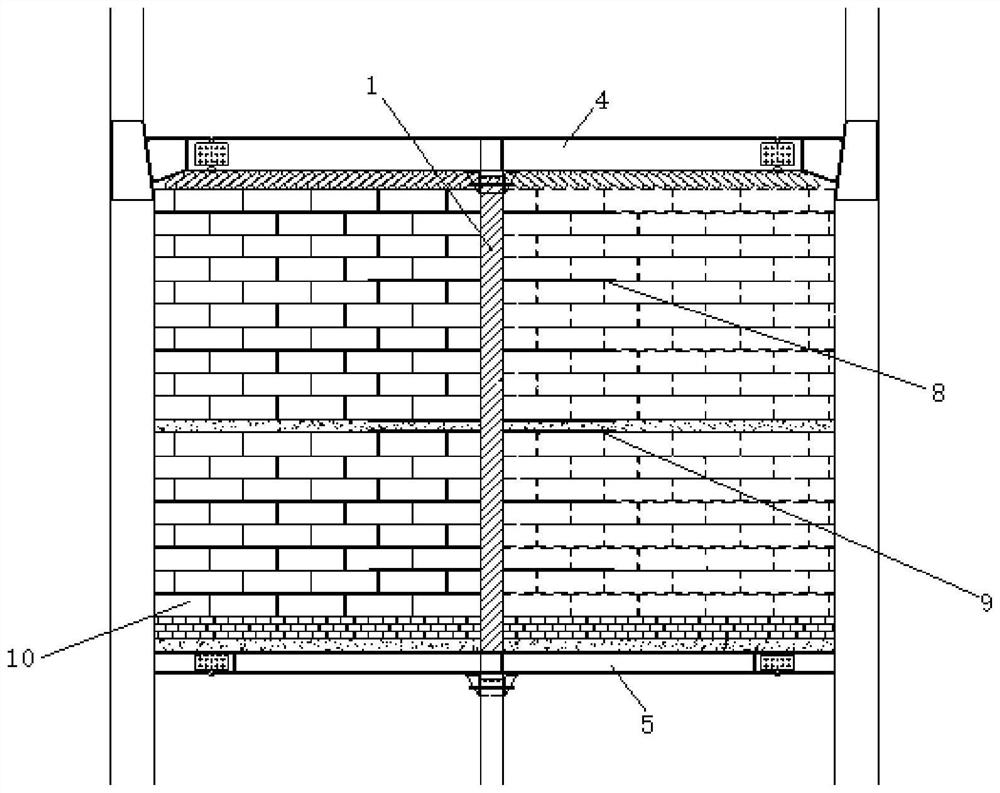

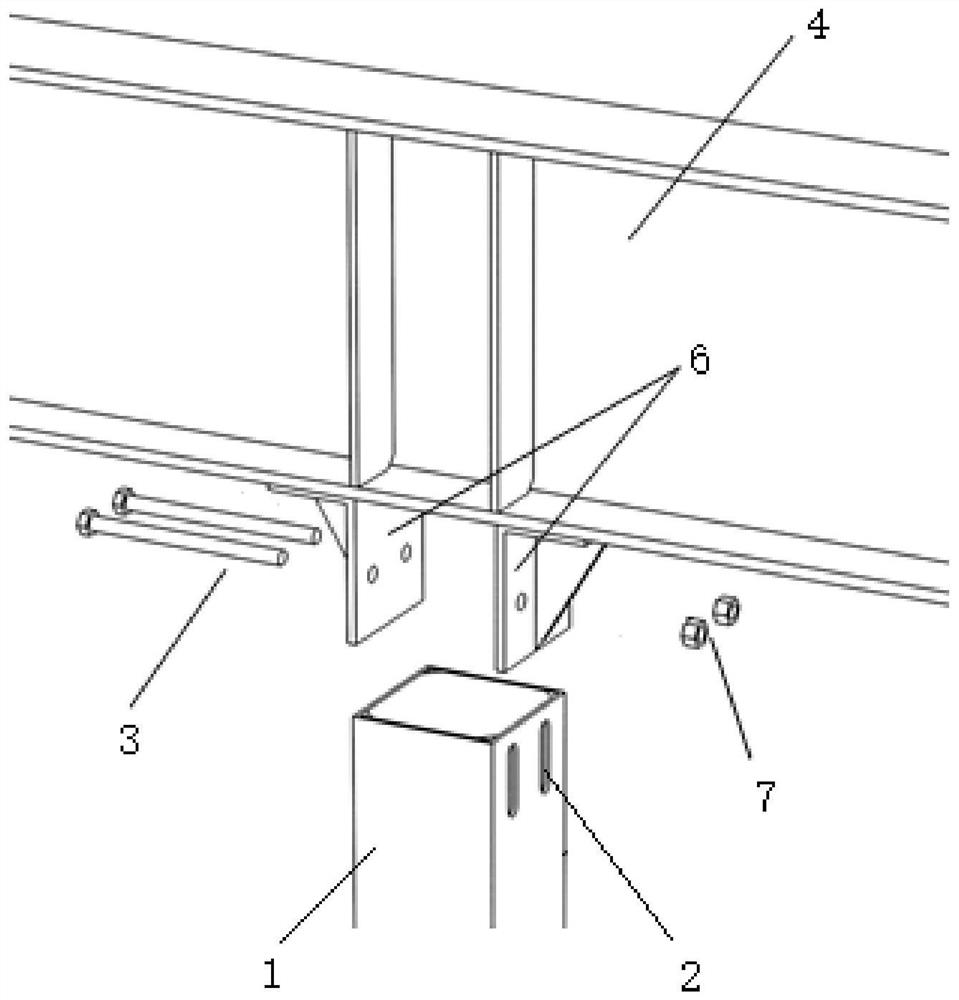

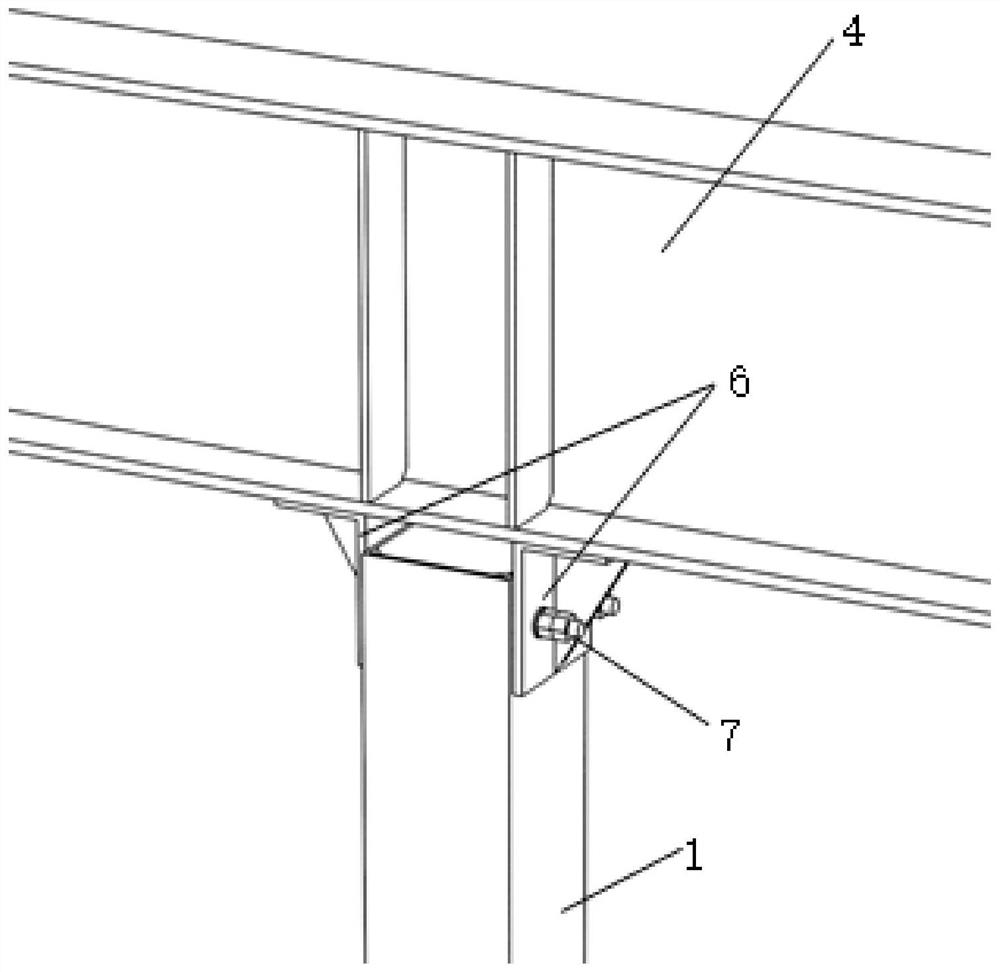

[0042] Such as Figures 1 to 5 A specific implementation of the installation method of the steel structure shown includes the following steps: fixing the lower end of the column 1 and the middle part of the bottom beam 5 by welding, placing the top beam 4 on the upper end of the column 1, and using the slider 3 to pass through the Set in the connecting piece 6 and the slideway 2, the sliding piece 3 is a bolt, and the sliding piece 3 and the connecting piece 6 are fixed on the upper end of the slideway 2 through the nut as the fastener 7, the connecting piece 6 is an angle steel, and the column 1 A sliding space for the top beam 4 is formed between the top of the top and the two connectors 6. When the floor is installed on the top beam 4, under the gravity of the floor, the top beam 4 slides in the sliding space, that is, sliding Part 3 slides from the upper end of slideway 2 to the lower end of slideway 2 .

[0043] When the steel structure provided by this embodiment is in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com