Scissor-type lifting mold-replacing trolley and full-automatic mold-replacing storage system thereof

A technology of mold trolley and lifting table, which is applied in the field of scissor-type lifting mold changing trolley and its automatic mold replacement storage system, which can solve the problems of increased labor intensity, large safety hazards, mold damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

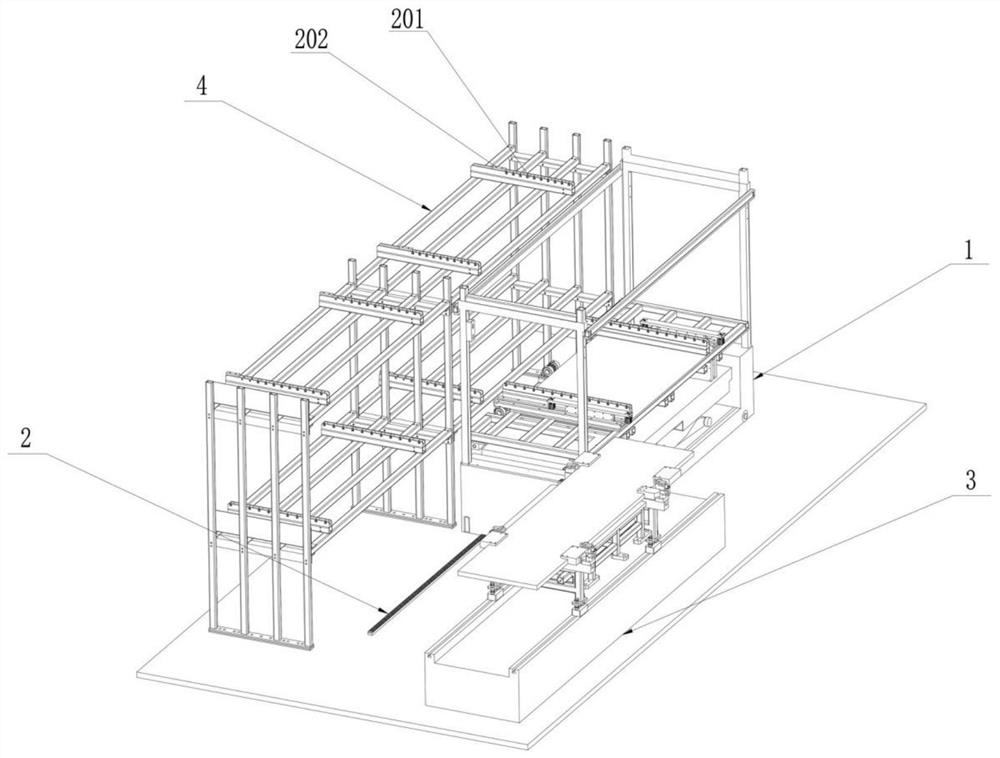

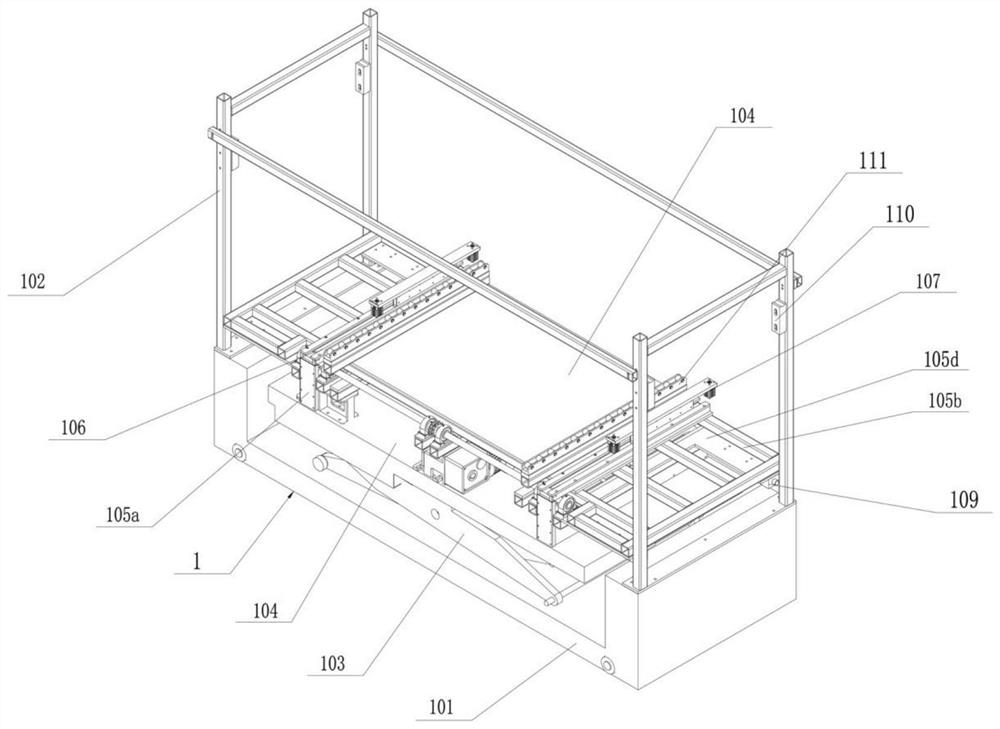

[0052] Such as figure 1 and figure 2As shown, a scissor-type lifting mold changing trolley includes a frame body 1, which is slidably mounted on a slide rail 2, and the two ends of the slide rail 2 extend to the machine platform 3 and multiple Layer mold frame 4, vehicle frame body 1 comprises: base 101, door frame 102, scissors arm 103, lifting platform 104, support frame 105 and two-way push-pull mechanism 107, door frame 102 is installed on the upper edge place of base 101, scissors arm 103 One end of which is fixed on the base 101, and the lifting platform 104 is installed on the end of the scissor arm 103 away from the base 101, so that the scissor arm 103 is clamped between the lifting platform 104 and the base 101, and the support frame 105 is installed on the lifting platform 104 On the end face, guide rails 106 are installed on both sides of the upper end face of the support frame 105 relative to its center line, and the two-way push-pull mechanism 107 is connected ...

Embodiment 2

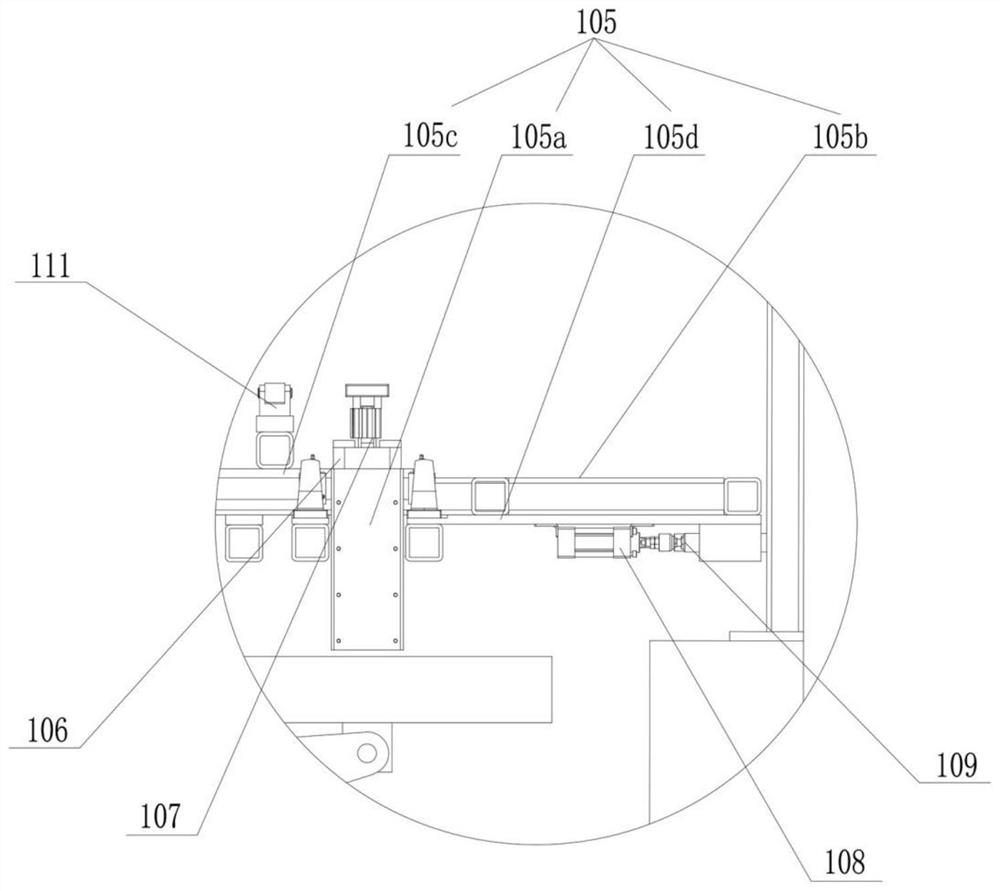

[0060] Such as figure 2 and image 3 As shown, in this embodiment, on the basis of the above-mentioned embodiment 1, one of the optimized designs is made. The support plate 105d is fixed below the two ends of the bracket 105b close to the door frame 102, and a plurality of second plates are installed on the support plate 105d. The cylinders 108 and the piston rods of each second cylinder 108 are connected with positioning pins 109 .

[0061] Such as figure 2 As shown, furthermore, the door frame 102 is provided with positioning seats 110 equal in number to the positioning pins 109 and corresponding one-to-one, and can abut against the positioning seats 110 when the positioning pins 109 are stretched out.

[0062] In this embodiment, the setting of the second cylinder 108, the positioning pin 109 and the positioning seat 110 can prevent the lifting platform 104 from falling, specifically, when the scissor arm 103 lifts the lifting platform 104, in order to ensure that the l...

Embodiment 3

[0064] Such as figure 1 and figure 2 As shown, in this embodiment, one of the optimized designs is made on the basis of the above-mentioned embodiment 1. The top plate 105c is provided with a first auxiliary wheel set 111 which is equal in number to the guide rail 106 and arranged along the length direction of the guide rail 106. There are second auxiliary wheel sets 201 equal in number to the first auxiliary wheel sets 111 on each storage position of the mold frame 4 .

[0065] Such as figure 1 As shown, further, the end of the second auxiliary wheel set 201 facing away from the first auxiliary wheel set 111 is provided with a limiting plate 202 to prevent dislocation of the mold.

[0066] In this embodiment, when the two-way push-pull mechanism 107 controls the movement of the mould, both the first auxiliary wheel set 111 and the second auxiliary wheel set 201 can change the sliding friction on the mold into rolling friction, thereby avoiding the occurrence of lowering of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com