Flexible hand-pushed skip car with gluing table

A rubber platform and flexible technology, applied in the field of flexible trolleys, can solve the problems of cumbersome operations, lack of versatility of transport vehicles, and manpower occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

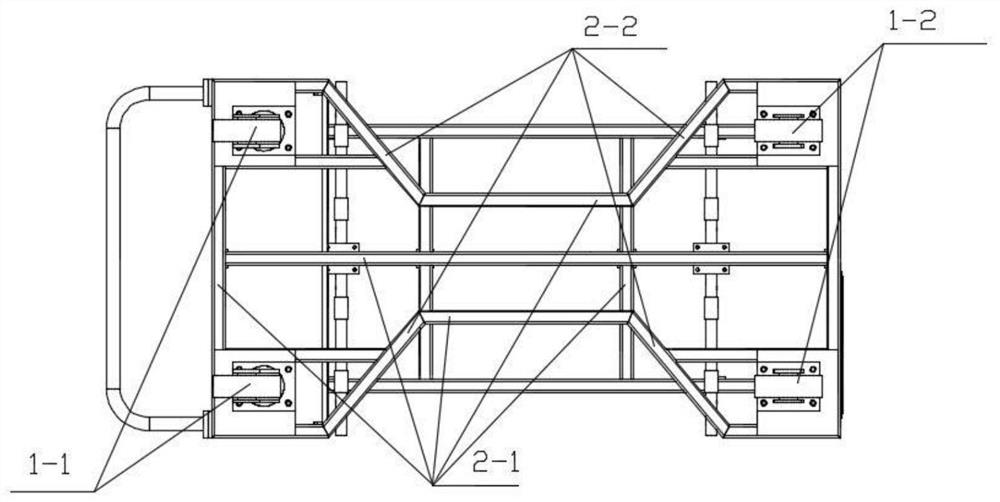

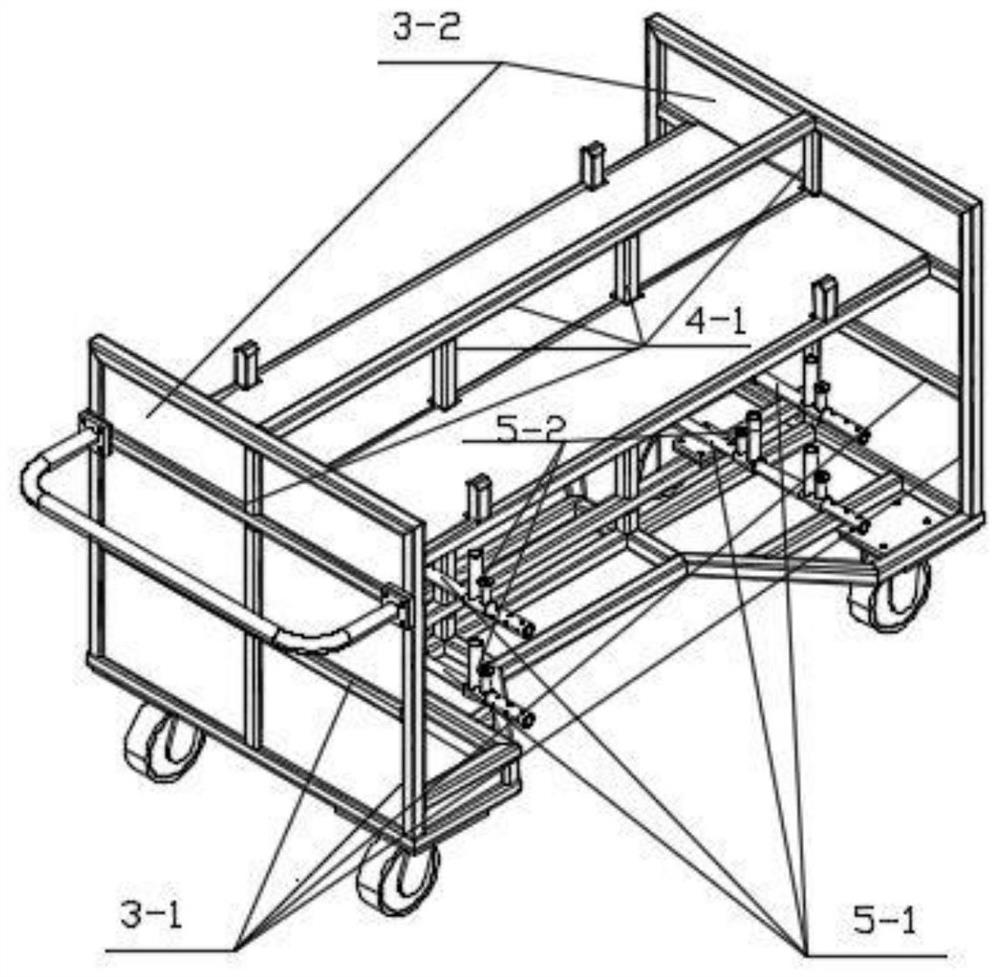

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention provides a kind of flexible trolley with gluing station, comprises caster part, underframe part, front and rear end plate part, middle frame part, workpiece bracket part, gluing table part, tool box part, The handlebar part; the caster part is installed at the bottom of the chassis part; the front and rear end plate parts are respectively fixed at the front and rear ends of the chassis part; the middle skeleton part is fixed between the front and rear end plate parts; the workpiece bracket part is installed on On the middle frame part; the gluing table part is fixed between the front and rear end plate parts and is located above the workpiece bracket; the tool box part is fixed on the bottom frame part and is located under the workpiece bracket part; the handlebar part is fixed on the end plate parts.

[0027] Such as figure 1 As shown, the caster part is composed of 4 directional c...

Embodiment 2

[0038] Such as Figure 4As shown, a flexible trolley with a gluing station, including caster parts, chassis parts, front and rear end plate parts, middle frame parts, workpiece bracket parts, gluing table parts, tool box parts, and handle parts ;The caster parts are installed at the bottom of the bottom frame parts; the front and rear end plate parts are respectively fixed on the front and rear ends of the bottom frame parts; the middle frame parts are fixed between the front and rear end plate parts; the workpiece bracket parts are installed on the middle frame parts above; the gluing platform part is fixed between the front and rear end plate parts and is located above the workpiece bracket; the tool box part is fixed on the bottom frame part and is located below the workpiece bracket part; the handlebar part is fixed on the end plate part.

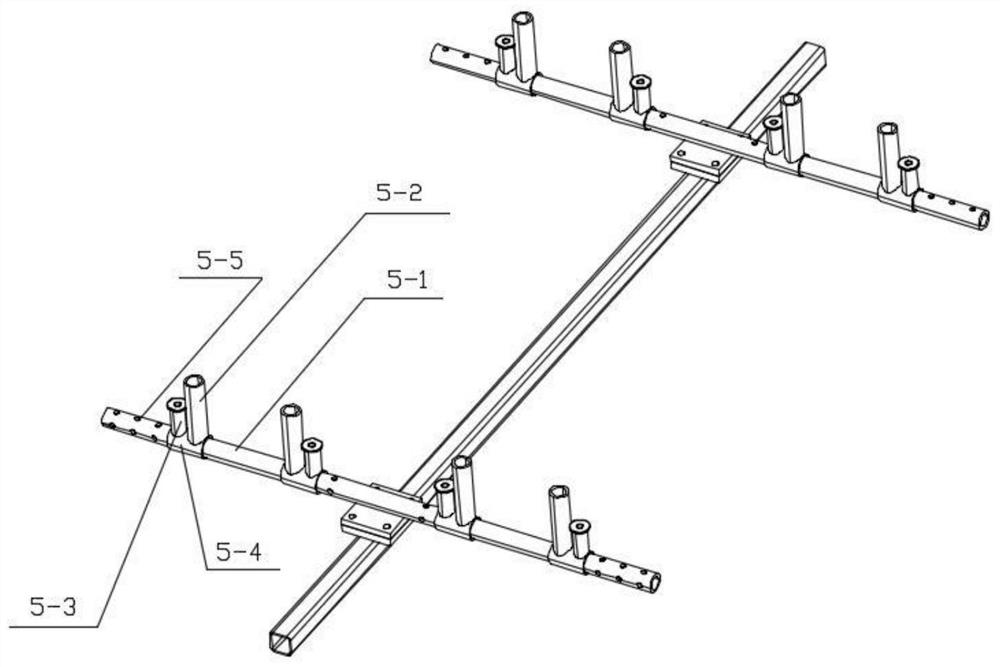

[0039] The workpiece bracket part is composed of a crossbeam 5-1 and a retaining post assembly, the crossbeam 5-1 is installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com