Roll printing and stamping equipment

A technology of stamping and equipment, applied in the field of rolling stamping and stamping equipment, can solve the problems of high labor intensity and low work efficiency of users, and achieve the effect of reducing labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

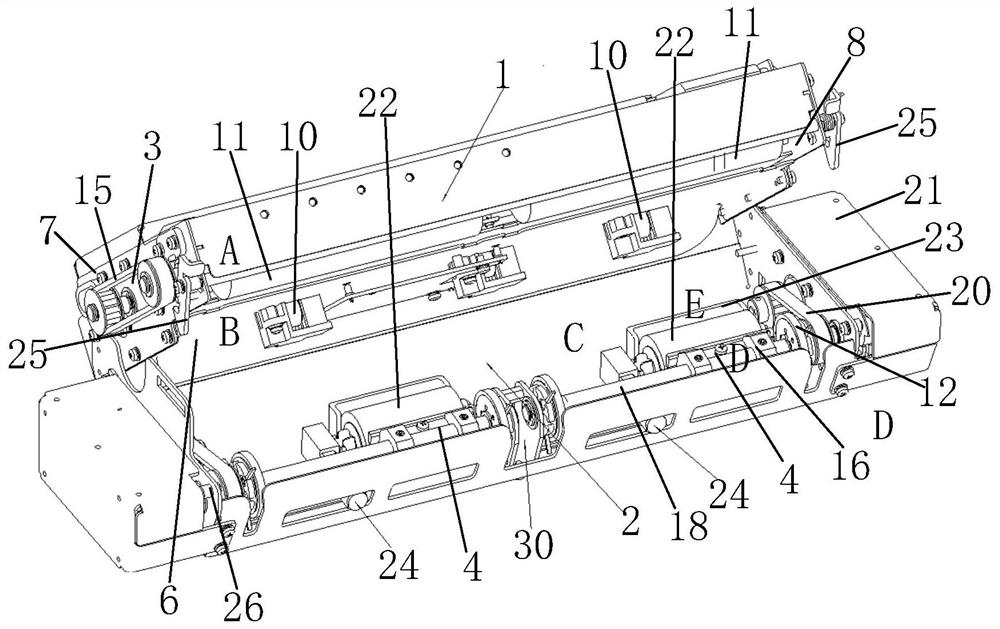

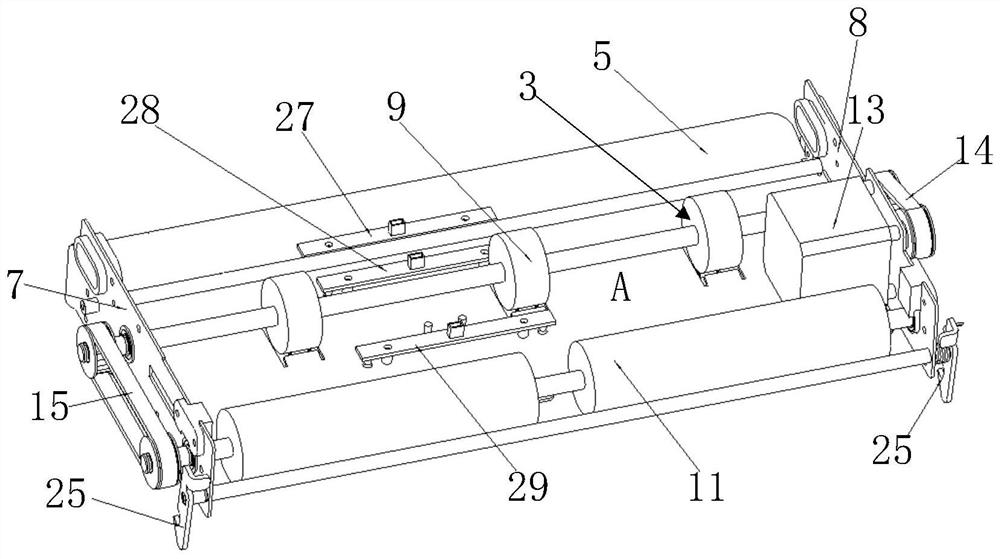

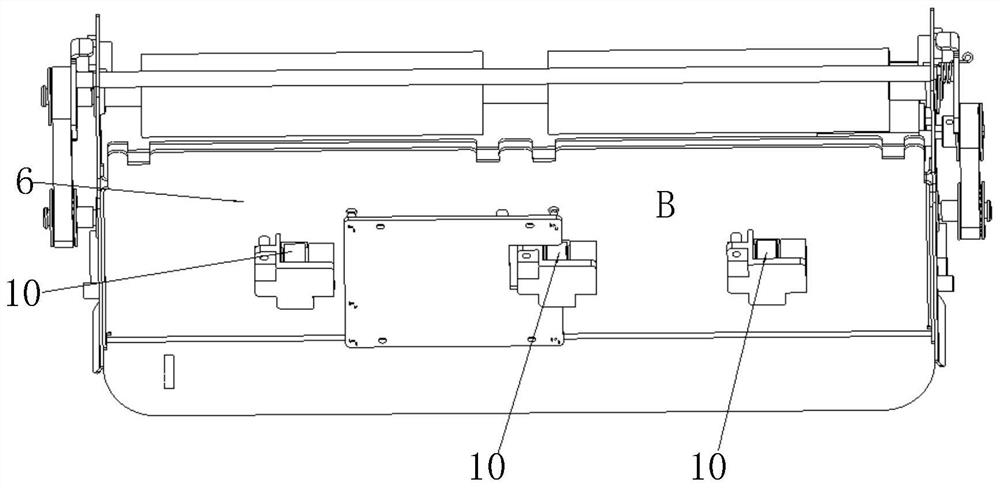

[0039] figure 1 It shows the overall structural diagram of the roll printing and stamping equipment. The structure of the rolling stamping and stamping equipment in the embodiment of the present invention is similar to that of a printer. figure 2 yes figure 1 The internal structure diagram of the top shell of the middle top mark 1, image 3 for figure 2 bottom view of the . Figure 4 for figure 1 The internal structure diagram of the bottom shell of the middle bottom logo 2. Figure 5 for Figure 4 The seal structure diagram at the bottom of the middle bottom shell, Figure 6 yes Figure 4 It is used to support the printing ink assembly seat of the sponge wheel. "A, B, C, D, E" in the figure represent cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com