Polyvinyl alcohol-based pesticide slow-release film and preparation method thereof

A technology of polyvinyl alcohol and polyvinyl alcohol material, applied in chemical instruments and methods, agriculture, agricultural machinery and other directions, can solve the problem of less sustained-release film, etc., and achieve the effect of strengthening the sustained-release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

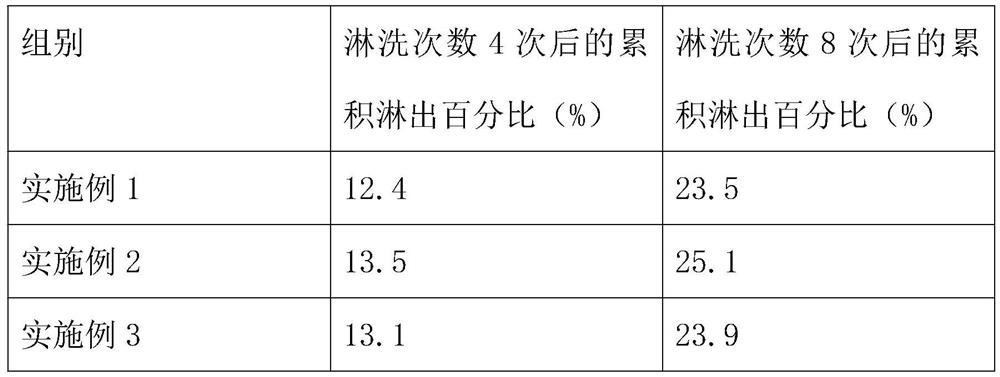

Examples

preparation example Construction

[0030] Preparation of carrier base material: According to the mass ratio of 20-30:3, take 20-30% sodium metaaluminate solution and sodium bicarbonate and mix them in a sealed container, adjust the pH to 9.2-10.3, at 40-60°C, Inject carbon dioxide gas at 3-8L / min, control the pressure of carbon dioxide gas to be greater than 0.1MPa, shake the liquid while ventilating, and after ventilating for 3-6min, carry out aging, separation, washing, and drying to obtain the carrier base material.

[0031] In the aging step, the aging temperature is 40-60° C., and the aging time is 60-90 minutes;

[0032] In the separation and washing step, the washing temperature is 30-50°C, and the washing times are 5-10 times; the pH value of the final washing wastewater is 6.8-7.3.

[0033] In the drying step, the drying temperature is 85-100° C., and the drying time is 4-8 hours.

[0034] A preparation method of a pesticide sustained-release film based on polyvinyl alcohol, comprising the steps of: ...

Embodiment 1

[0040]A pesticide slow-release film based on polyvinyl alcohol, in parts by weight, comprises the following components:

[0041] 10 parts of mixed polyvinyl alcohol material, 14 parts of carrier base material, 1 part of pesticide abamectin, 0.5 part of biochar, 1 part of lauryl betaine, 0.1 part of formaldehyde, 2 parts of glycerin, 0.2 part of auxiliary agent, 110 parts water.

[0042] Mixed polyvinyl alcohol material, that is, a mixture of lower molecular weight polyvinyl alcohol and higher molecular weight polyvinyl alcohol, modified by polyvinyl alcohol with a molecular weight of 1000 and polyvinyl alcohol with a molecular weight of 5000 according to the mass ratio of 5:1:0.01 combination of agents.

[0043] Auxiliary: mix starch and dextrin at a mass ratio of 4:1 to obtain the auxiliary.

[0044] Modifier: take silane coupling agent KH-550 and nano-titanium dioxide at a mass ratio of 3:0.01.

[0045] Preparation of the carrier base material: Mix 30% sodium metaaluminat...

Embodiment 2

[0055] A pesticide slow-release film based on polyvinyl alcohol, in parts by weight, comprises the following components:

[0056] 15 parts of mixed polyvinyl alcohol material, 20 parts of carrier base material, 3 parts of pesticide abamectin, 1.8 parts of biochar, 3 parts of dodecyl betaine, 0.4 parts of formaldehyde, 5 parts of glycerin, 0.5 parts of auxiliary agent, 130 parts water.

[0057] Mixed polyvinyl alcohol material, that is, a mixture of lower molecular weight polyvinyl alcohol and higher molecular weight polyvinyl alcohol, modified by polyvinyl alcohol with a molecular weight of 2000, polyvinyl alcohol with a molecular weight of 8000, and a mass ratio of 8:3:0.01 combination of agents.

[0058] Auxiliary: mix starch and dextrin at a mass ratio of 8:1 to obtain an auxiliary.

[0059] Modifier: take silane coupling agent KH-550 and nano titanium dioxide at a mass ratio of 7:0.01.

[0060] Preparation of the carrier base material: Mix 30% sodium metaaluminate solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com