Anti-static EPE pearl cotton butt bonding treatment method

A processing method and technology of pearl cotton, which is applied in the field of pearl cotton, can solve the problems of pearl cotton dislocation or flattening, viscous failure, and difficulty in gluing at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

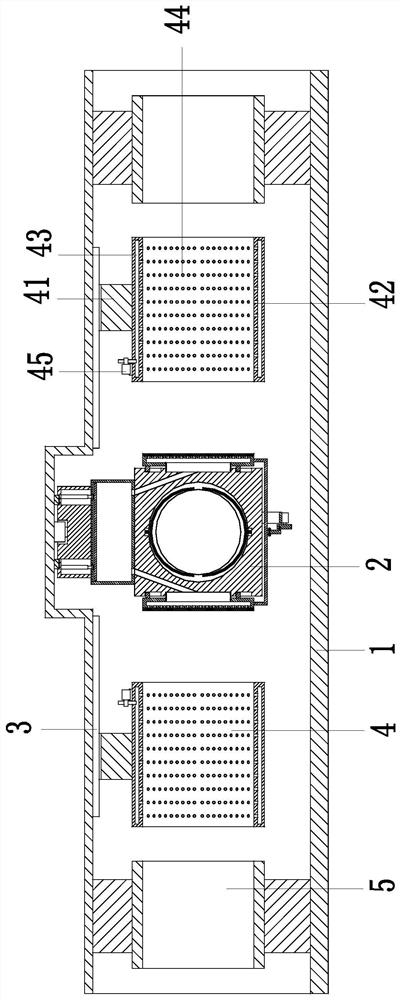

[0029] Such as Figure 1 to Figure 5 As shown, an antistatic EPE pearl cotton butt bonding treatment method uses a glued butt joint device, which includes an outer frame 1, a glue unit 2, two electric sliders 3, two The positioning unit 4 and the two placement sleeves 5, using the above-mentioned glue-coated butt joint equipment to deal with the antistatic EPE pearl cotton butt joint bonding are as follows:

[0030] S1. Air suction positioning: use two positioning units 4 to perform air suction positioning on two tubular pearl cotton;

[0031] S2, smearing: Extrude the glue in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com