Balancing ring forming mold

A technology for forming molds and balance rings, which is applied to household appliances, other household appliances, and household components, etc. It can solve problems such as uneven contact, affecting product demoulding quality, and difficult assembly of bumps, so as to reduce rework rate and replacement Difficulty of maintenance, effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The following are specific embodiments of the invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

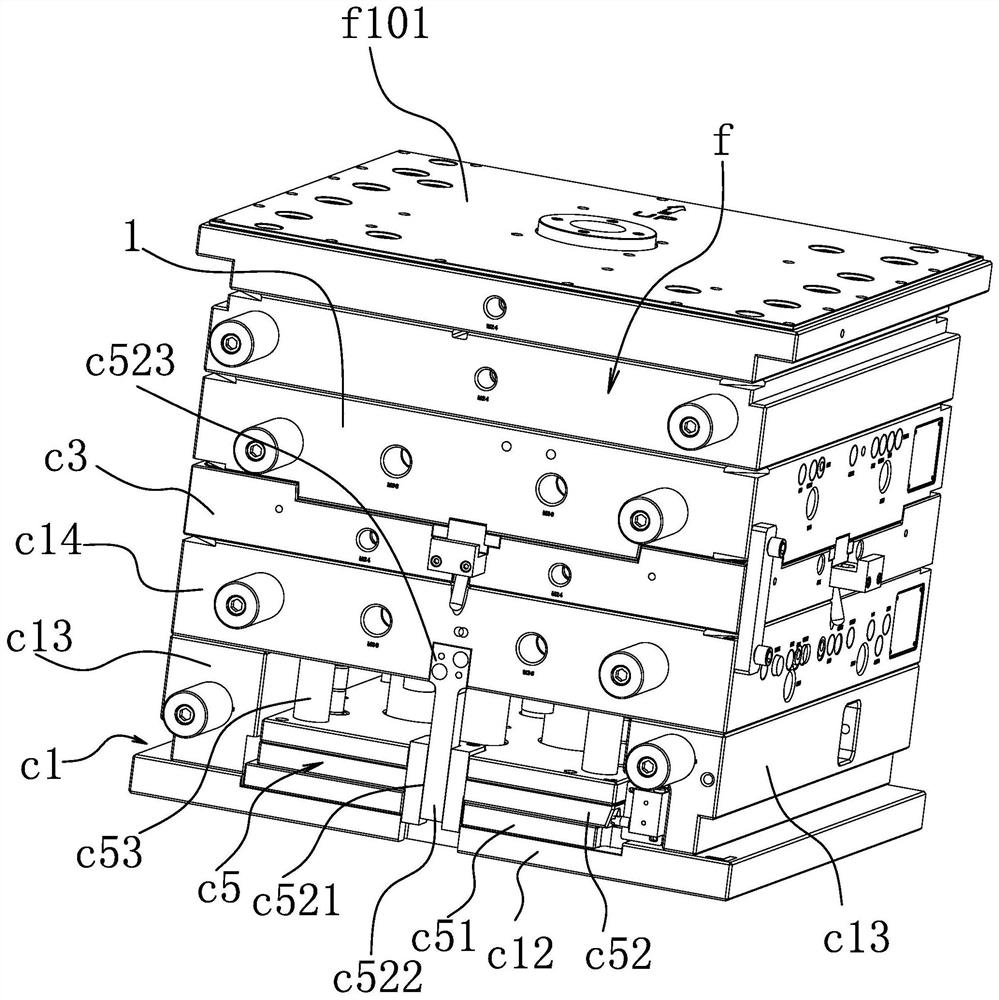

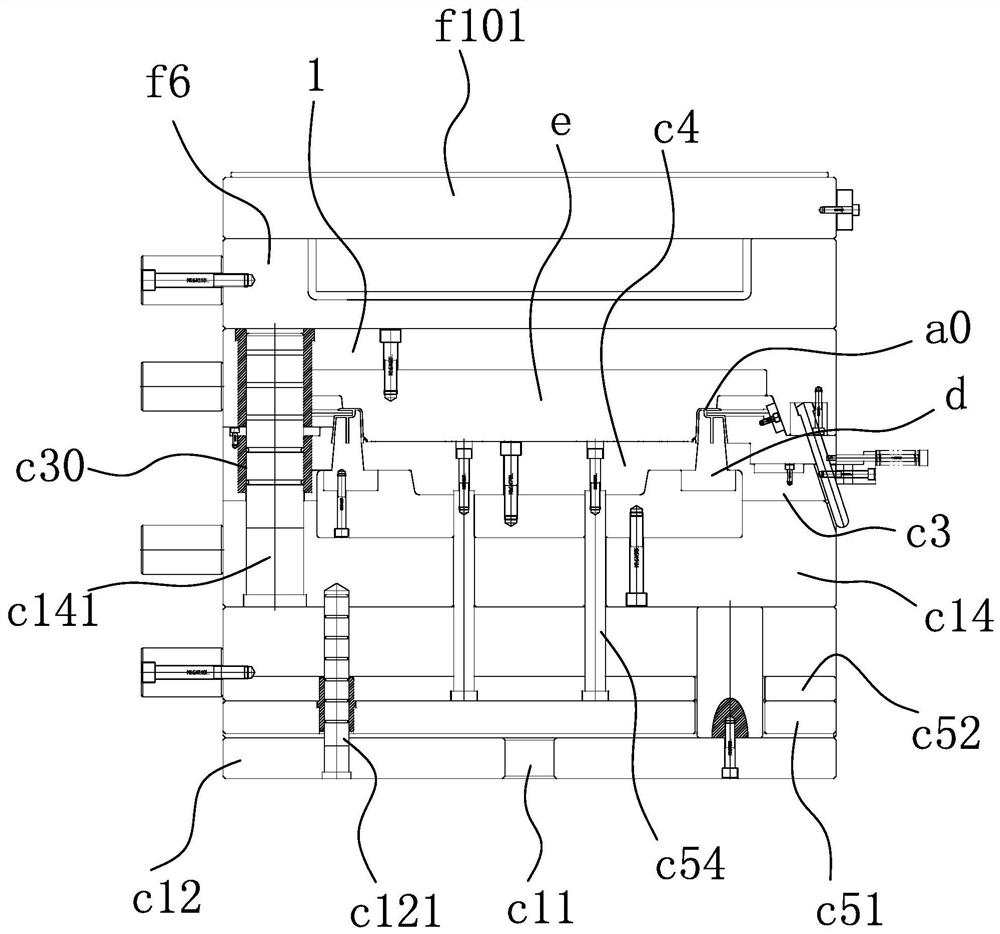

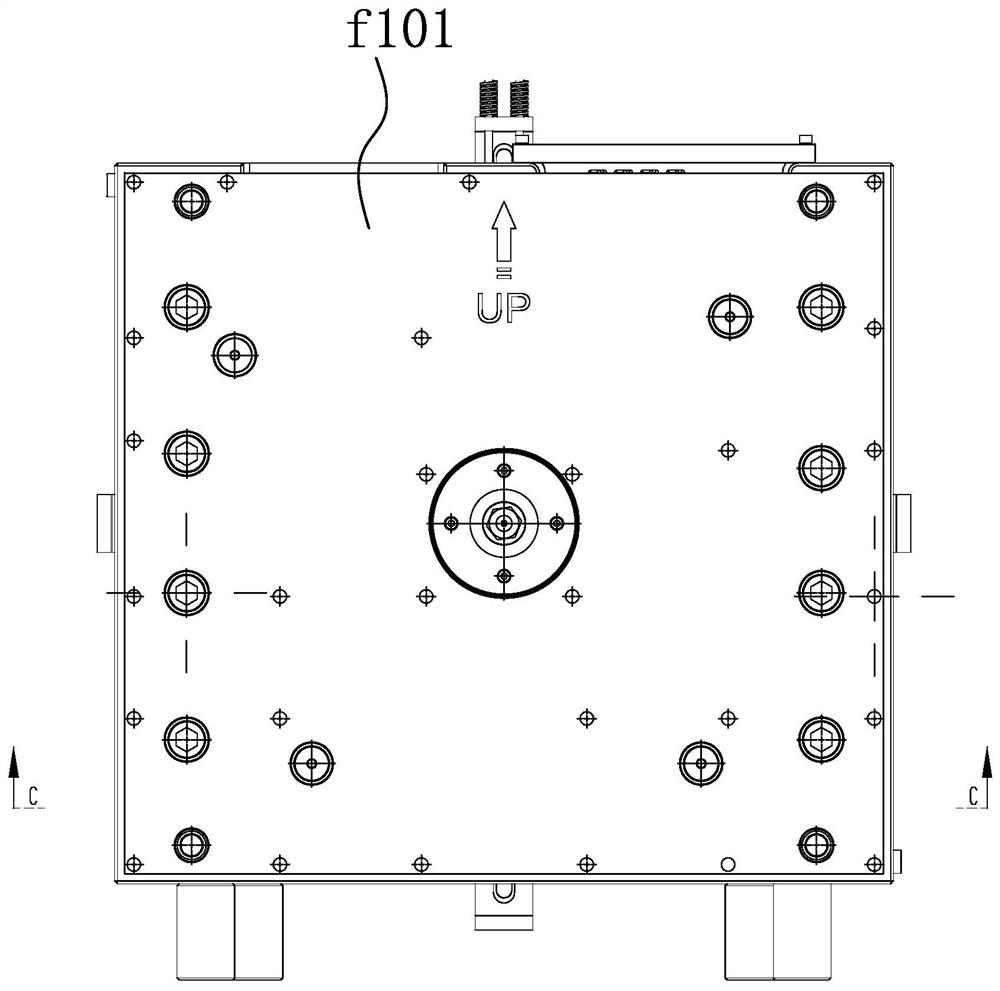

[0049] like Figure 1-2 and Figure 4 As shown, the balance ring forming mold includes a mold base c1, and the mold base c1 includes a fixed bottom plate c12, a support block c13 fixed on the upper surface of the corresponding two sides of the fixed bottom plate c12, and a fixed support block c13 fixed on the upper surface of the two support blocks c13 The middle plate c14, the fixed middle plate c14 is an annular plate.

[0050] like Figure 6-10 as shown,

[0051] A combined annular core punch d is fixed on the mold base c1, and the combined annular core punch d includes a circular base d1 arranged horizontally, and the circular base d1 is made of mold steel material. The circular base d1 is convenient for lathe processing. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com