A molding die for automobile exhaust manifold and its implementation method

A technology for automobile exhaust and molding molds, which is applied to casting molding equipment, cores, casting molds, etc., can solve problems such as poor production efficiency, lower utilization rate of molten iron, and small recovery rate of cold iron, so as to simplify processing difficulty, Improved operation and reduced temperature drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

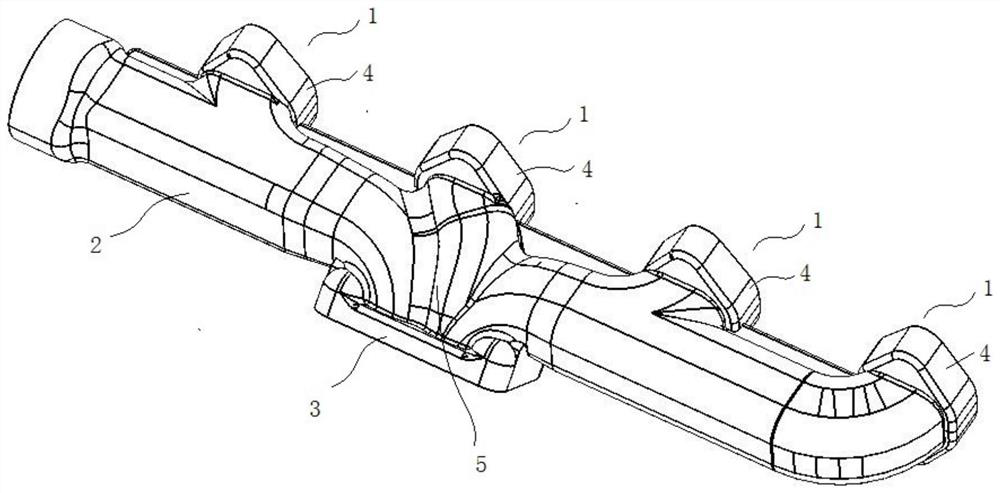

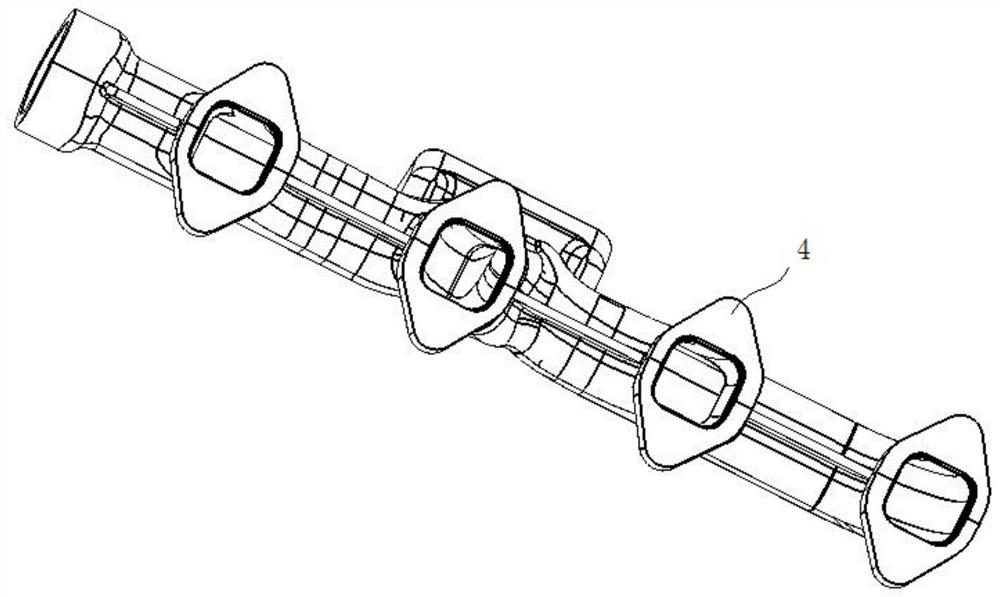

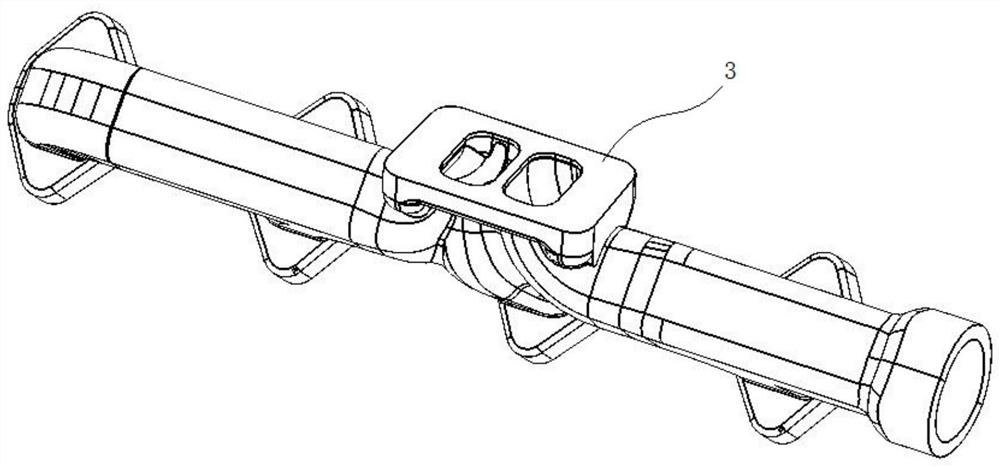

[0034] Such as Figure 1-3 , the automobile exhaust manifold involved in this embodiment has a structure comprising four dry branch pipes 1 and a main pipe 2, the four branch pipes 1 communicate with the main pipe 2, the mouth of the branch pipe 1 is a small flange 4, and the pipe body of the main pipe is provided with a large flange The flange 3, the big flange 3 and the branch pipe 1 are on different sides, the four branch pipes 1 are aligned in a straight line, and the nearby main pipe part of the big flange 3 corresponds to the isolated heat joint 5 when the cast iron is formed.

[0035] Such as Figure 4-6 , the forming mold of the automobile exhaust manifold includes an upper mold and a lower mold, and the symmetrical plane of the four branch pipes 1 is used as a dividing plane, an upper mold is formed on the surface of the upper mold, and a lower mold is formed on the surface of the lower mold. At the same time, in order to realize the pouring of molten iron, an upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com