Low-noise food processor

A food processing machine and machine base technology, which is applied in kitchen utensils, home utensils, applications, etc., can solve problems such as complex structure, poor noise reduction effect, and complex structure of feeding cover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

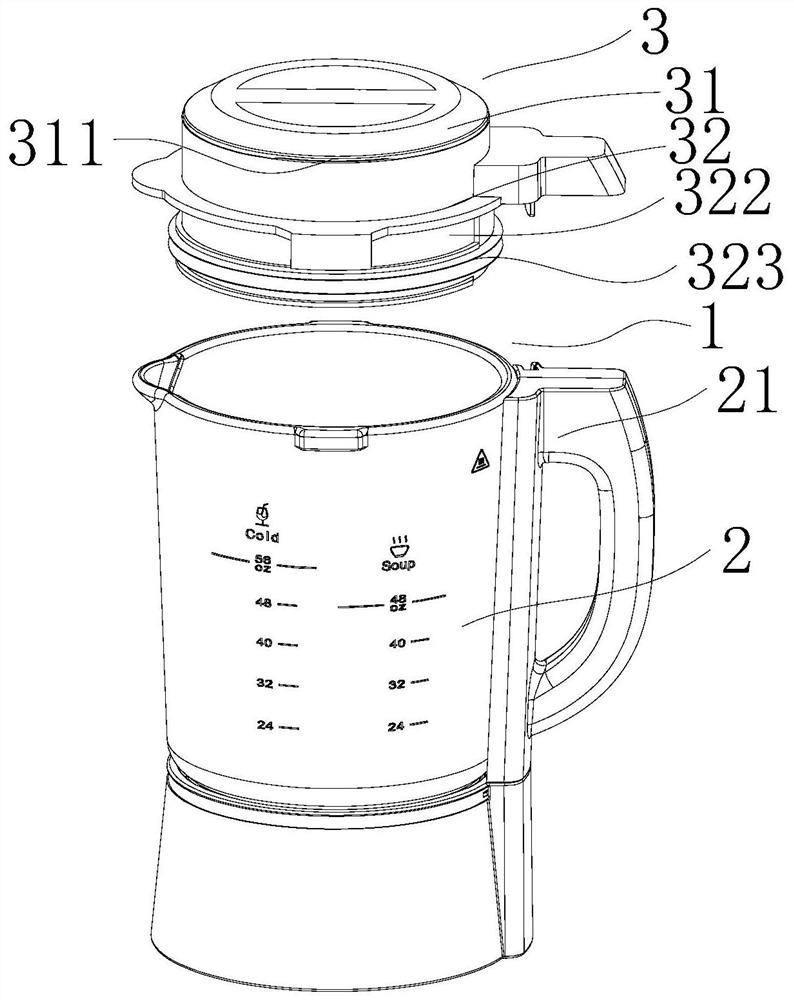

[0031] The structure of the food processing machine of the present embodiment is as Figure 1 to Figure 3 As shown, the food processing machine includes a machine base (not shown) and a stirring cup 1 arranged on the machine base. The stirring cup 1 is detachably connected to the machine base to facilitate cleaning of the stirring cup 1. The machine base is provided with a motor (not shown) and a circuit board (not shown), the stirring cup 1 includes a cup body 2 and a cup cover 3, a handle 21 is provided on one side of the cup body 2, and a crushing knife (not shown) is arranged in the cup body 2 , the upper end of the motor shaft of the motor passes through the machine base and is connected to the lower connector, and the lower end of the cutter shaft of the crushing knife is connected to the upper connector. , so that the motor can drive the pulverizer to rotate in the cup body 2 to pulverize food.

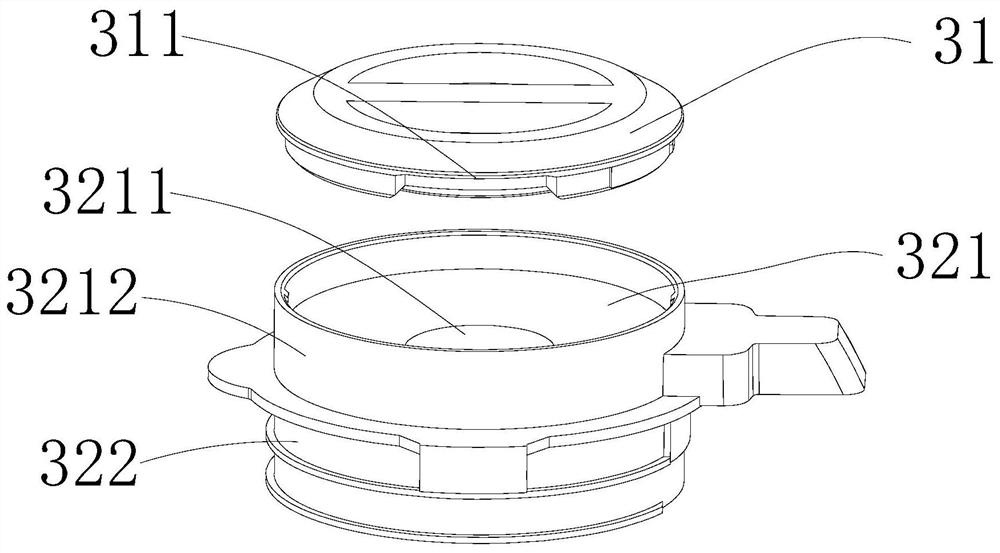

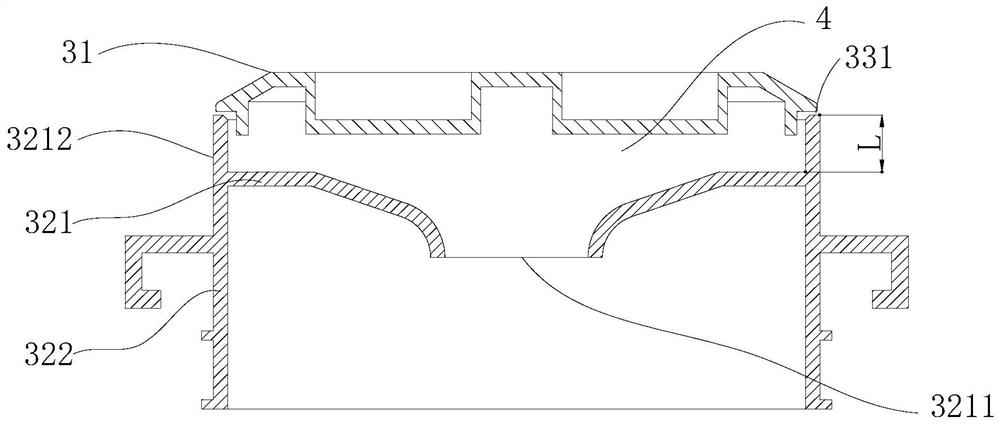

[0032] The cup cover 3 includes an upper cover 31 and a lower cover 32, t...

Embodiment 2

[0042] The difference between this embodiment and Embodiment 1 is that the structure of the sound-absorbing chamber is different, combining Figures 4 to 6 As shown, the silencing cavity 4 of this embodiment at least includes a first silencing cavity 41 and a second silencing cavity 42, and the first silencing cavity 41 and the second silencing cavity 42 are communicated through a first communication gap 51, so that inside the cup body 2 After the generated noise enters the first muffler cavity 41 from the through hole 3211, it is attenuated for the first time, and then enters the second muffler cavity 42 through the first communication gap 51, and is attenuated for the second time, and finally passes through the exhaust gap 311 for the second time. Discharged after three attenuations, the noise has been greatly attenuated and no longer affects the user.

[0043] A first baffle plate 61 is arranged inside the muffler cavity 4, and the first baffle plate 61 is separated from th...

Embodiment 3

[0051] The difference between the present embodiment and the second embodiment is that the structure of the sound-absorbing chamber is different, combining Figure 7 and Figure 8 As shown, the silencing cavity 4 of this embodiment also includes a third silencing cavity 43, the third silencing cavity 43 communicates the second silencing cavity 42 with the exhaust slit 311, and the second silencing cavity 42 and the third silencing cavity 43 pass through The second communication slit 52 is connected, so that the noise generated in the cup body 2 enters the first silencing cavity 41 from the through hole 3211 and is attenuated for the first time, and then enters the second silencing cavity 42 through the first communication slit 51 to obtain the first noise reduction cavity 42. The second attenuation, and then enter the third muffler cavity 43 through the second communication gap 52, and obtain the third attenuation, and finally pass through the exhaust slit 311 for the fourth a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com