Crimp contact

A contact and crimping connection technology, which is applied in the direction of contact manufacturing, connecting contact materials, connecting device parts, etc., can solve problems such as unsatisfactory crimping connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

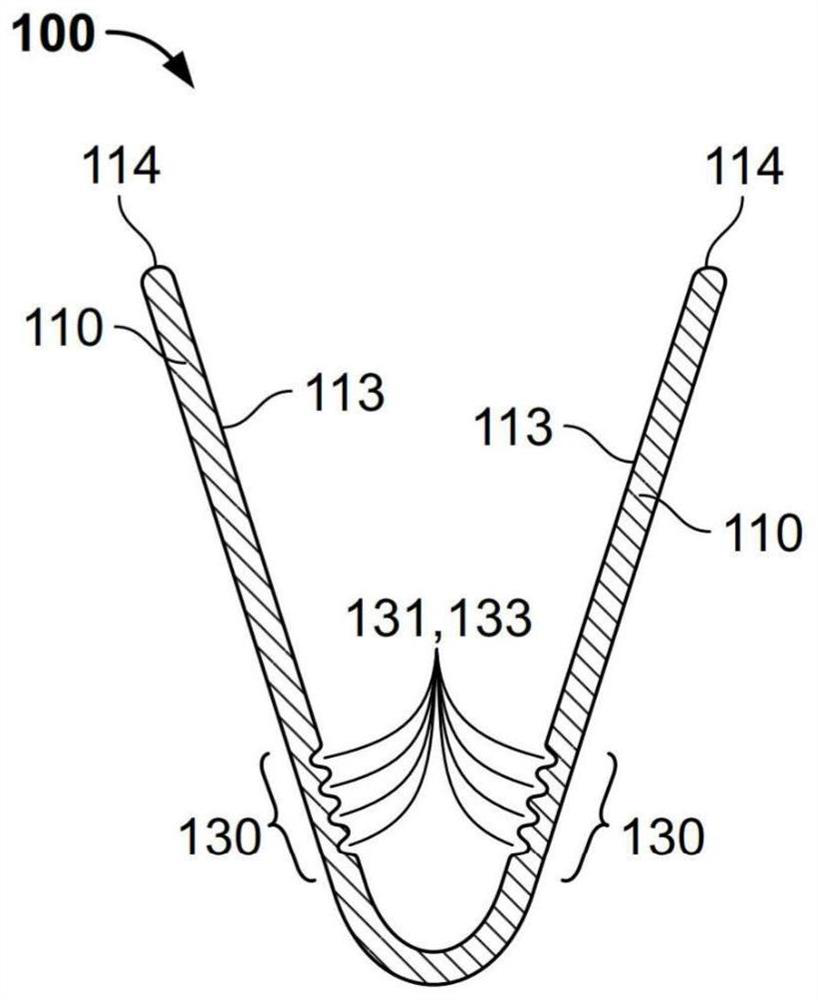

[0040] figure 1 A crimp contact 100 is shown, which is suitable for crimping figure 1 conductors not shown. The crimping contact 100 has at least one crimping side 110 which can be crimped. figure 1 Two such crimp sides 110 are shown in . In this case, the crimp side 110 serves to surround the conductor after crimping. The crimp contact 100 also has a receptacle 120 for the conductor, which extends in the longitudinal direction 101 of the crimp contact 100 as far as the receiving end 121 . The crimp side 110 extends on the receiving end 121 in the longitudinal direction 101 to the front end 111 . The front region 112 of the crimp contact 100 is arranged between the receiving end 121 and the front end 111 . In the front region 112 of the crimp contact 100 it has a structured region 130 .

[0041] figure 1 The two crimping sides 110 are shown forming a crimping sleeve 102 into which a conductor can be inserted before crimping. Furthermore, the crimp contact 100 has a con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com