Full-automatic pneumatic control device

A fully automatic, component-controlled technology, applied in valve devices, valve operation/release devices, engine components, etc., to solve problems such as poor functionality and reliability, incompleteness, and difficulty in draining condensed water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

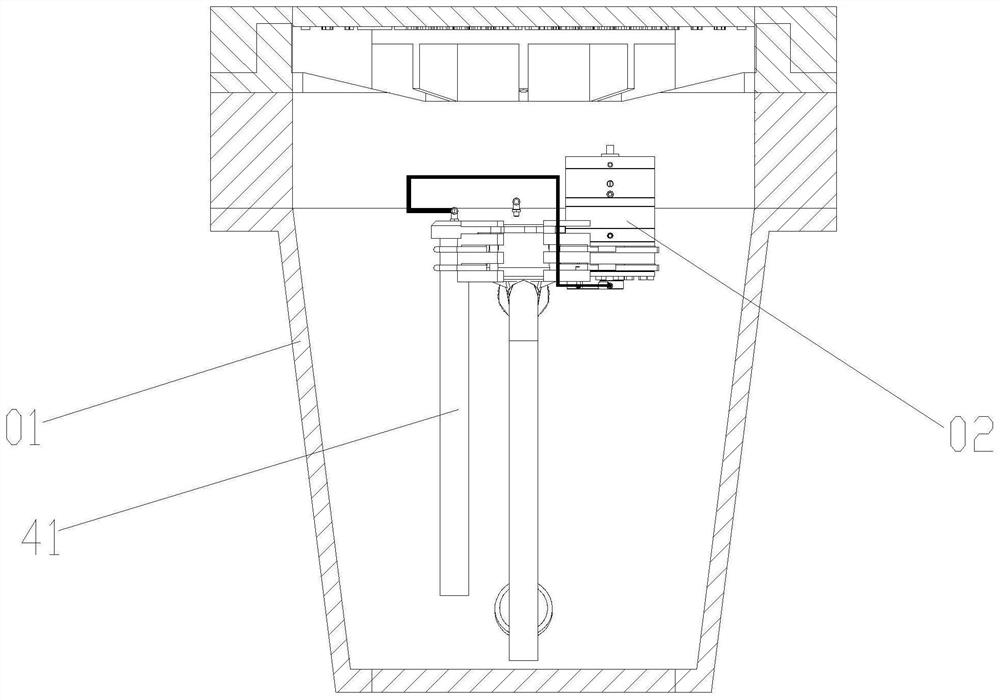

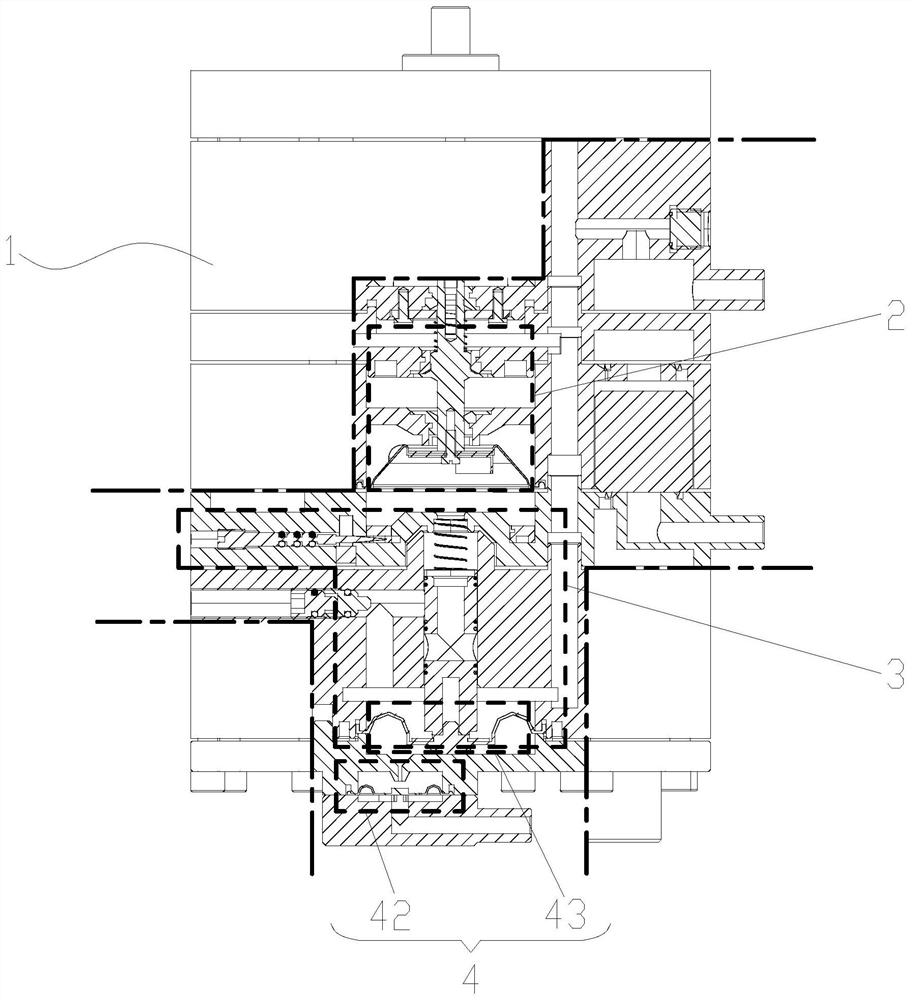

[0079] Such as figure 1 As shown, a fully automatic pneumatic control device is installed in the vacuum well 01, and is used to transport the sewage in the vacuum well 01 to the downstream vacuum collection pipeline network, which is figure 1 Parts labeled "02", such as figure 2 As shown, its structure includes a housing 1, an executive assembly 2 and a power assembly 3 installed in the housing 1, a control assembly 4 that triggers the power assembly 3 to drive the execution assembly 2 to work; the execution assembly 2, the power assembly 3 and the control assembly 4 Distributed sequentially from top to bottom.

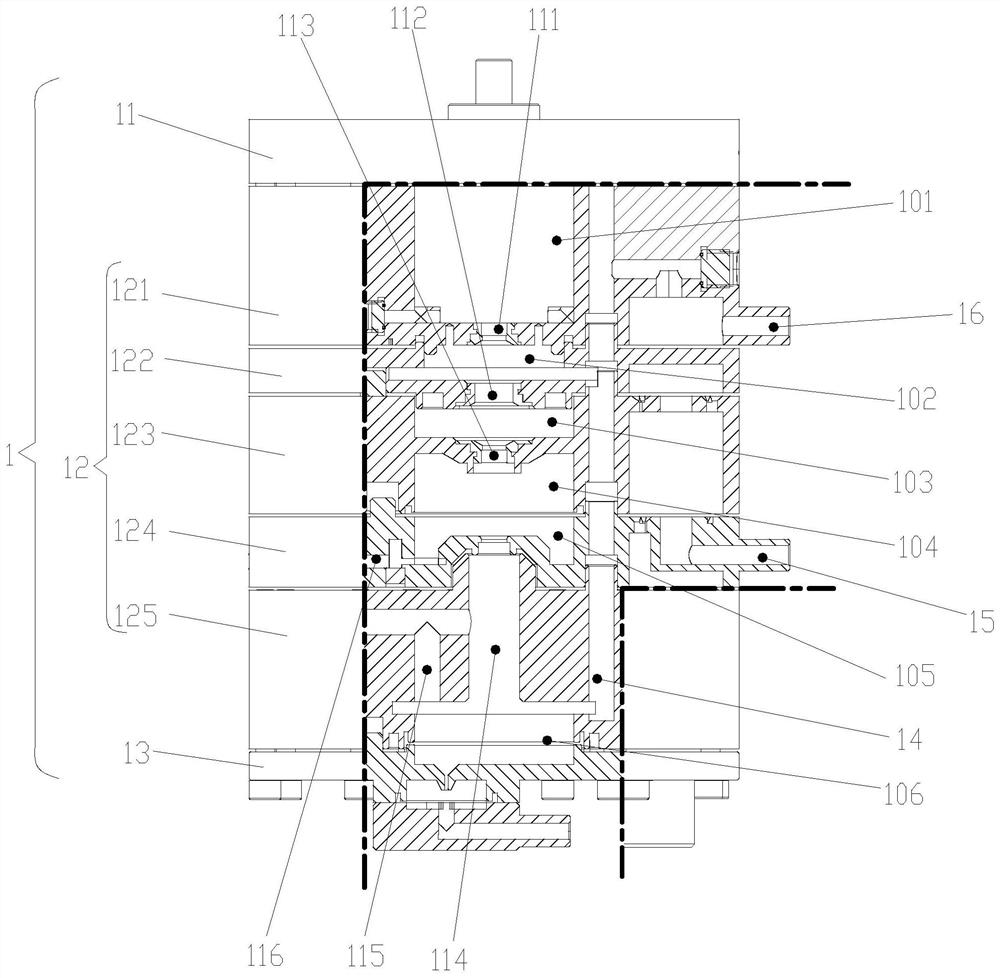

[0080] Such as image 3 As shown, the housing 1 includes an upper housing 11, a middle housing 12 and a lower housing 13 arranged sequentially from top to bottom. In order to facilitate the processing of each space inside the middle housing 12, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com