Green energy-saving fabricated building and construction method

A prefabricated and architectural technology, applied in construction, separation methods, sustainable buildings, etc., can solve problems such as large water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

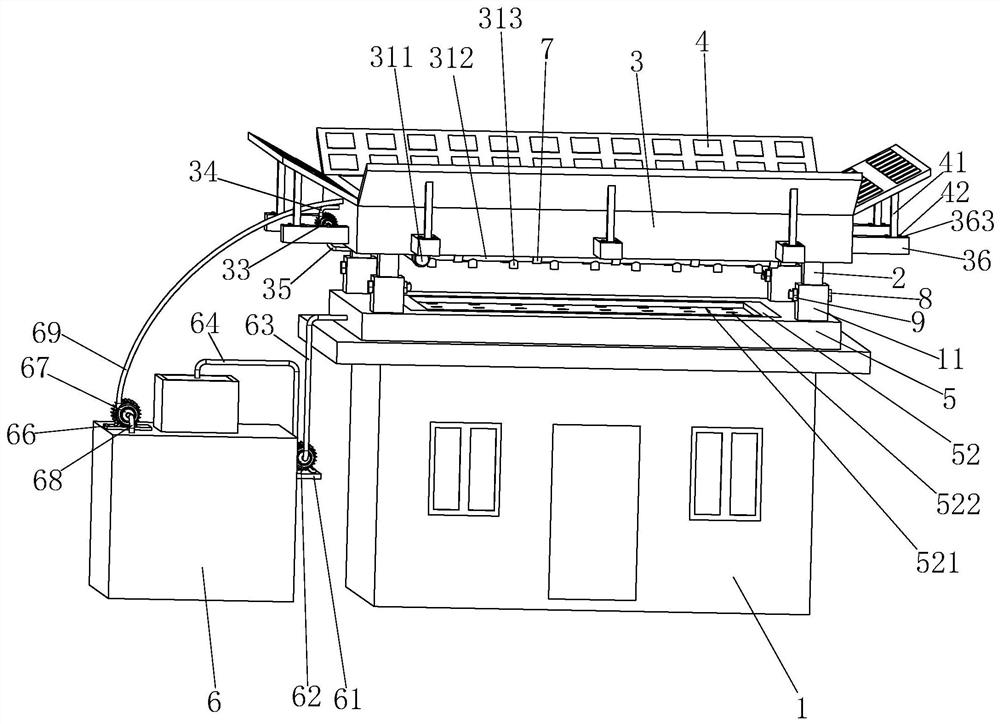

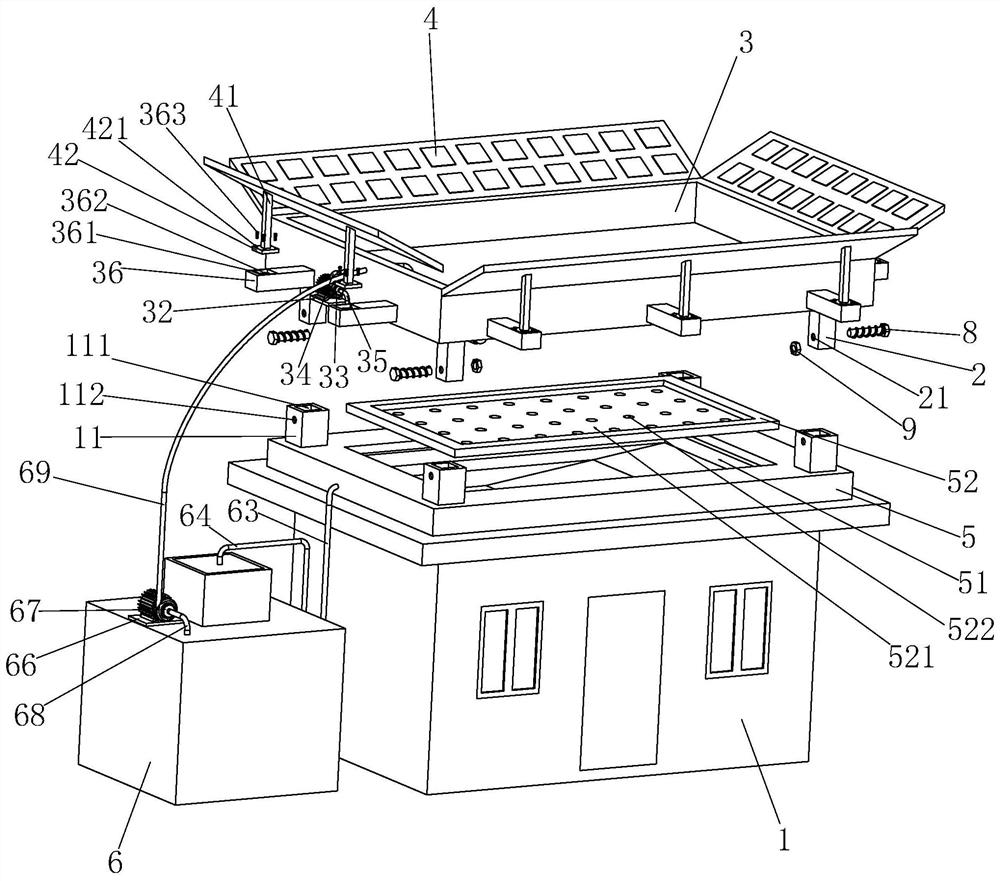

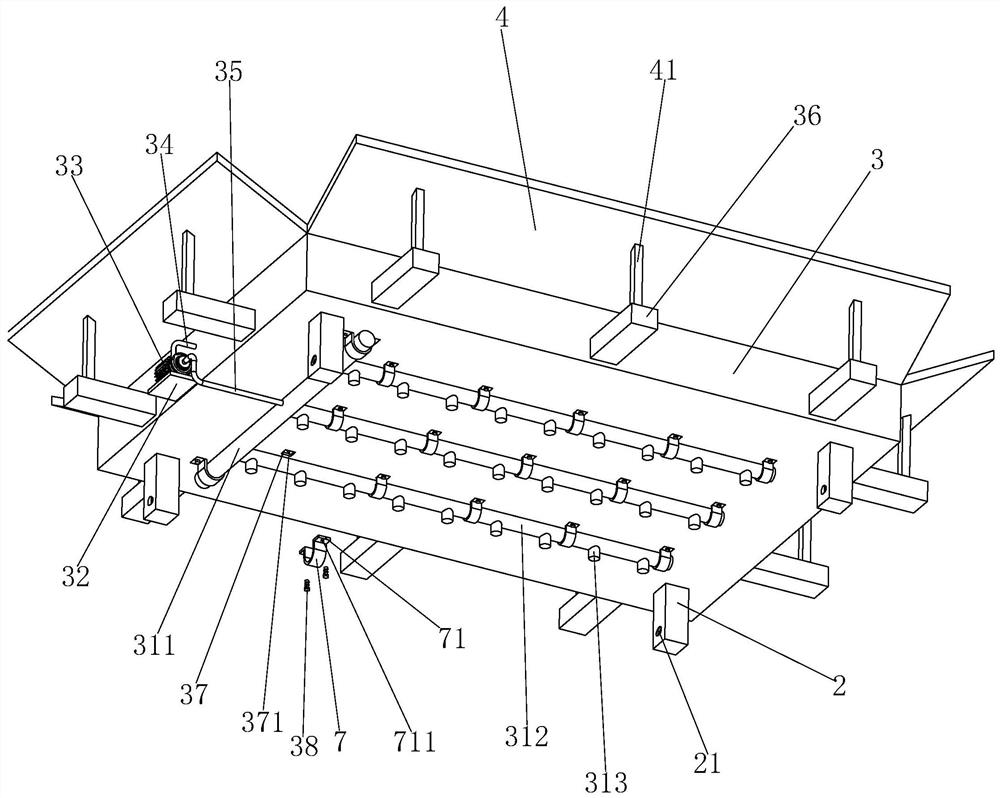

[0044] The following is attached Figure 1-4 The application is described in further detail.

[0045] The embodiment of the present application discloses a green energy-saving prefabricated building. refer to figure 1 , the prefabricated building includes a prefabricated house 1, the prefabricated house 1 is constructed by using light steel as the skeleton and assembling a plurality of sandwich panels through multiple components, and the prefabricated house 1 is mostly used in construction On-site temporary housing or temporary storage warehouses, so through such a simple and fast prefabricated house 1, not only the construction is convenient and fast, the construction time is shortened, but also the material and labor costs are saved, so that it can meet the architectural concept of environmental protection, energy saving, fast and efficient.

[0046] And in real life, can feel very hot in the room of this prefabricated house 1, generally by spraying water continuously on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com