Preparation method for loading metal oxide on surface of cracked carbon black

A technology of surface loading and oxide, applied in chemical instruments and methods, dyeing physical treatment, fibrous fillers, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

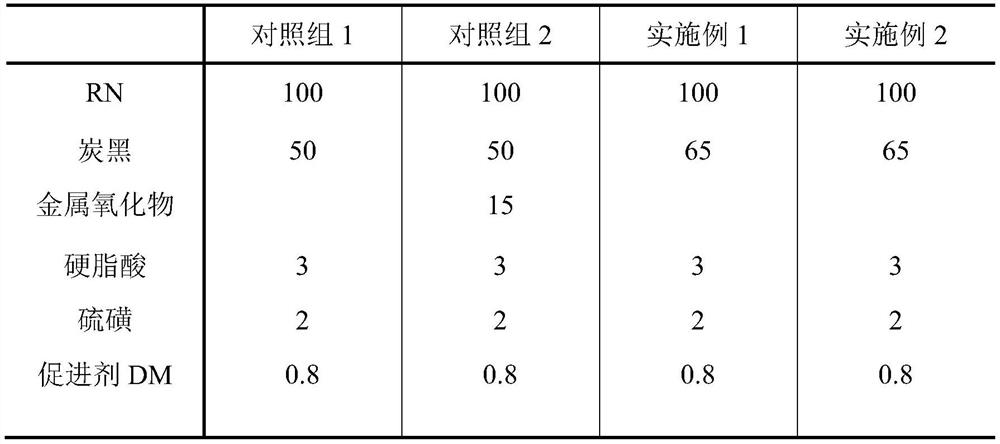

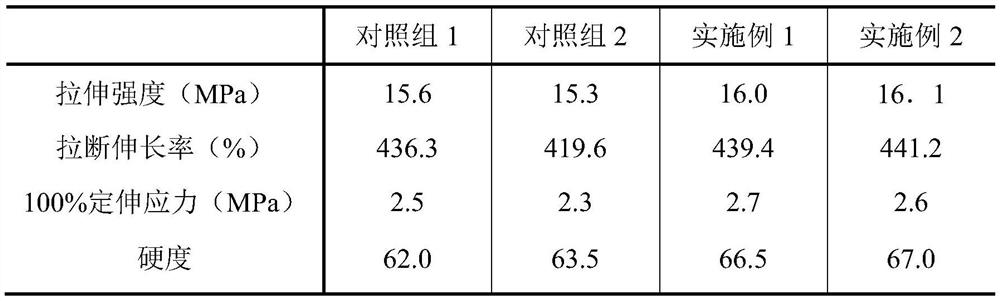

Embodiment 1

[0020] A preparation method for loading metal oxide on the surface of pyrolysis carbon black, comprising the following steps:

[0021] S1. After washing and drying the cracked carbon black with clean water, place it in a vacuum environment and dry it at 90°C for 1 hour;

[0022] S2, after cleaning and drying, place in the vacuum reaction tank, add alcohol solvent simultaneously, vacuumize in the vacuum reaction tank, exhaust and release pressure again, through 3 times of vacuumizing-pressure release treatment, make alcohol solvent Can enter the surface and internal pores of pyrolysis carbon black;

[0023] Wherein, the alcoholic solvent is one or more of methanol, ethanol, isopropanol;

[0024] S3. Heating and aging: heat the vacuum reaction tank, raise the temperature to 50°C, keep for 2 hours, then sieve and drain, recover the alcohol solvent, collect and recycle the alcohol solvent through distillation, and crack the obtained carbon black drying;

[0025] S4, loaded meta...

Embodiment 2

[0028] A preparation method for loading metal oxide on the surface of pyrolysis carbon black, comprising the following steps:

[0029] S1. After washing and drying the cracked carbon black with clean water, place it in a vacuum environment and dry it at 90°C for 1 hour;

[0030] S2, after cleaning and drying, place in the vacuum reaction tank, add aromatic hydrocarbon solvent at the same time, vacuumize in the vacuum reaction tank, exhaust and release the pressure again, through 3 times of vacuuming-pressure relief treatment, so that the solvent can Enter the cracked carbon black surface and internal pores;

[0031] Wherein, the aromatic hydrocarbon solvent includes one or more of benzene, toluene, xylene;

[0032] S3. Heating and aging: heating the vacuum reaction tank, raising the temperature to 60° C., keeping it for 2 hours, then sieving and draining, recovering the solvent, collecting and reusing the solvent through distillation, and drying the obtained cracked carbon bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com