Buckwheat husk filling pad bagging machine

A technology for filling pads and buckwheat husks, applied in the field of filling pads, can solve the problems of heavy workload, complicated operation and high production costs for staff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

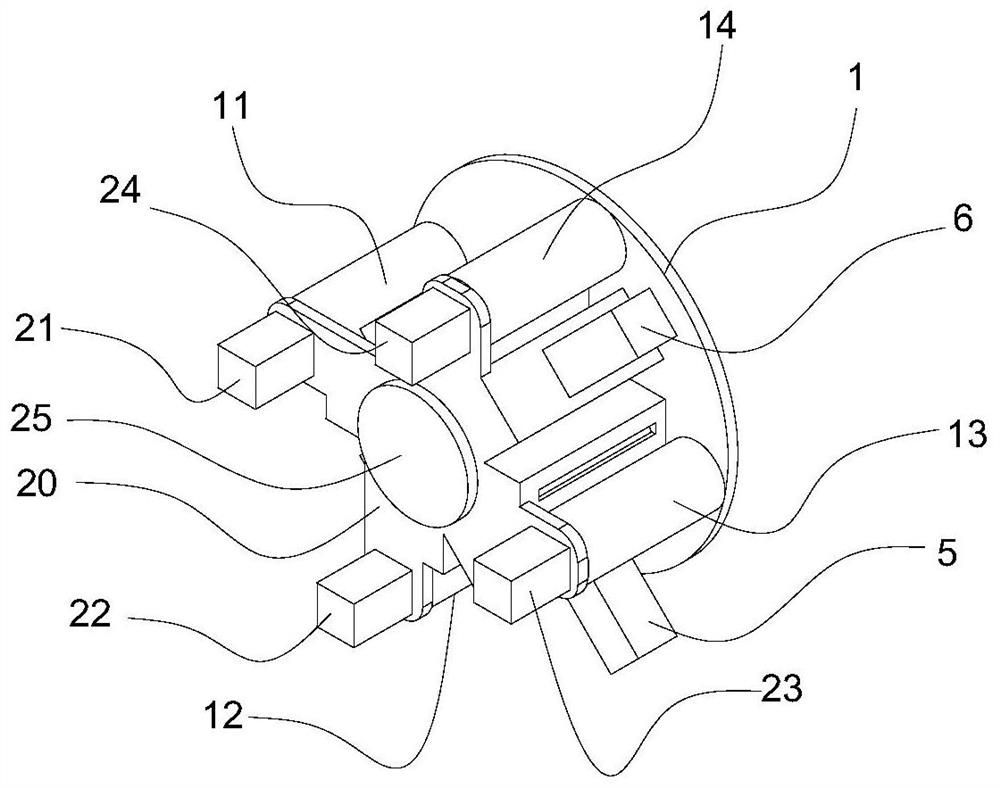

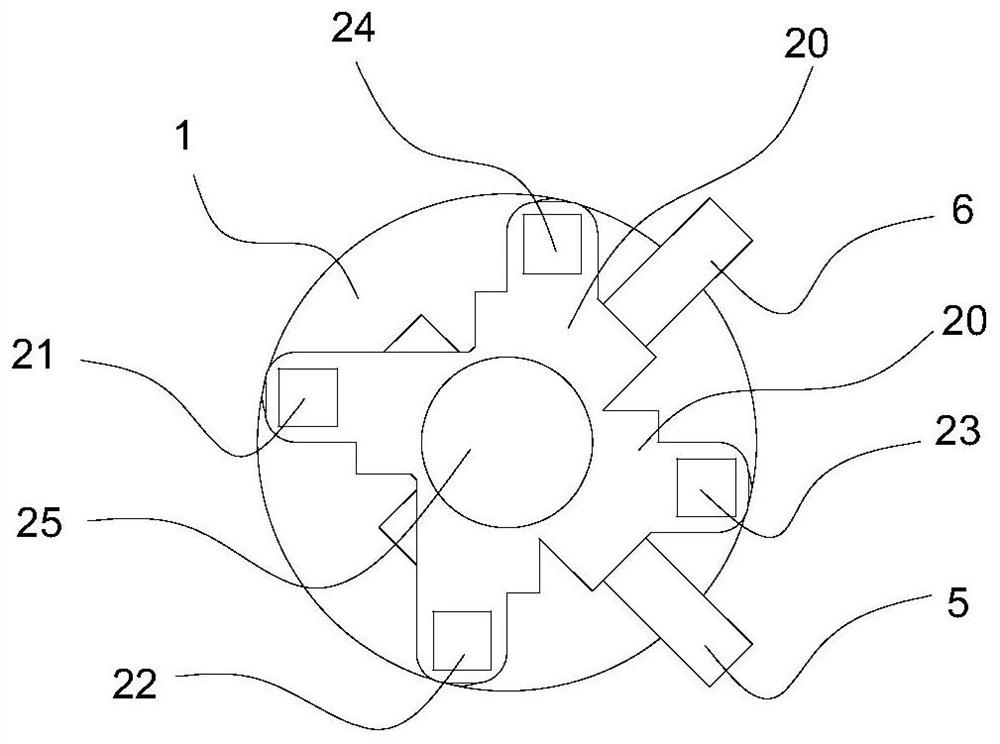

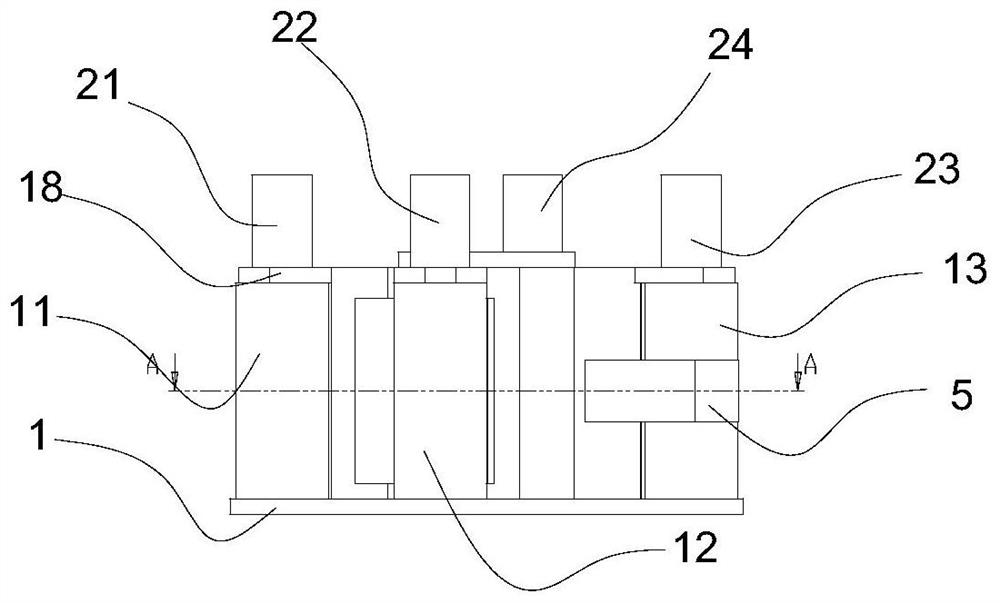

[0050] Such as Figure 1 to Figure 6 As shown, the buckwheat shell filling pad bagging machine of the present invention includes a mounting plate 1; an organism 20 is arranged on the mounting plate 1;

[0051] The body 20 has a square cavity 2; the four top corners of the square cavity 2 are provided with cloth guide nozzles, which are respectively the first cloth guide nozzle 7, the second cloth guide nozzle 8, and the third cloth guide nozzle 9 , the fourth cloth guide nozzle 10; and the four cloth guide nozzles are all provided with a cloth guide groove connected to the square cavity 2;

[0052] One side of the first cloth guide nozzle 7 is provided with a finished product winding roller 11; one side of the second cloth guide nozzle 8 is provided with a lower cloth winding roller 12; one side of the third cloth guide nozzle 9 An intermediate cloth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com