A device for reducing dust at the bottom of clinker silo and its application method

A technology of clinker warehouse and unloading device, which is applied in the directions of transportation, packaging, loading/unloading, etc. It can solve the problems of poor environment at the bottom of the clinker warehouse, high maintenance rate of equipment, leakage of fine materials, etc., and achieves convenient and reliable use, improved Environmental sanitation conditions, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further explained below in conjunction with the accompanying drawings and examples, and the protection scope of the present invention cannot be limited by this. The purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

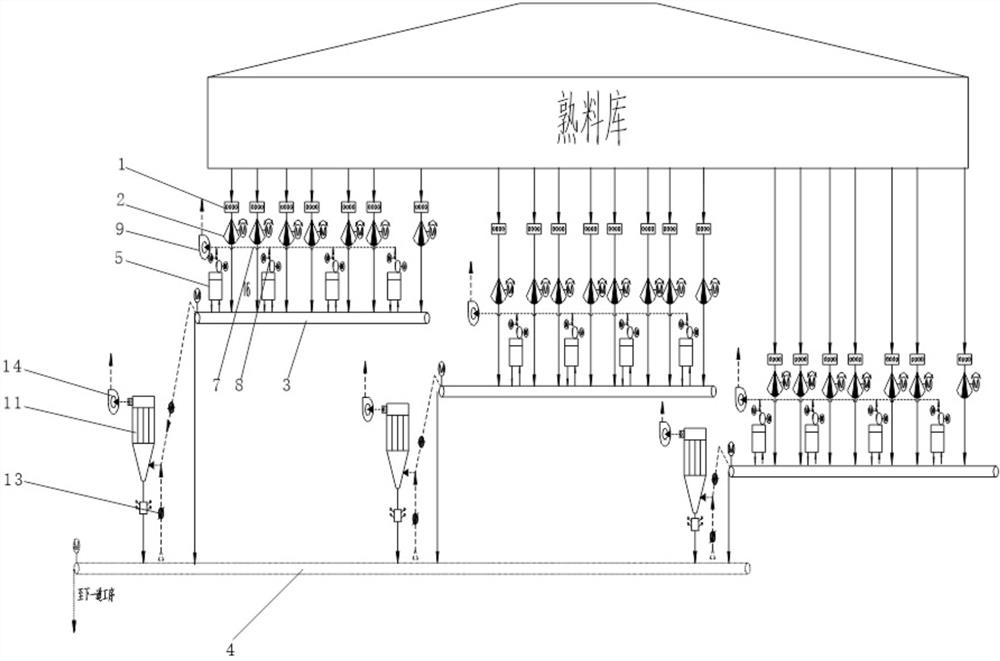

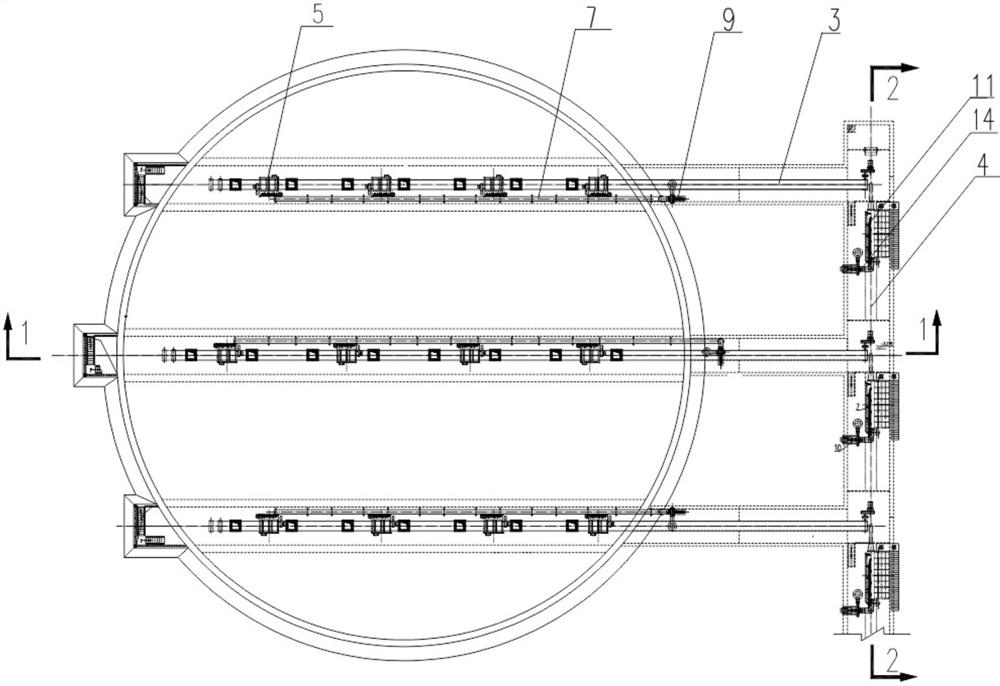

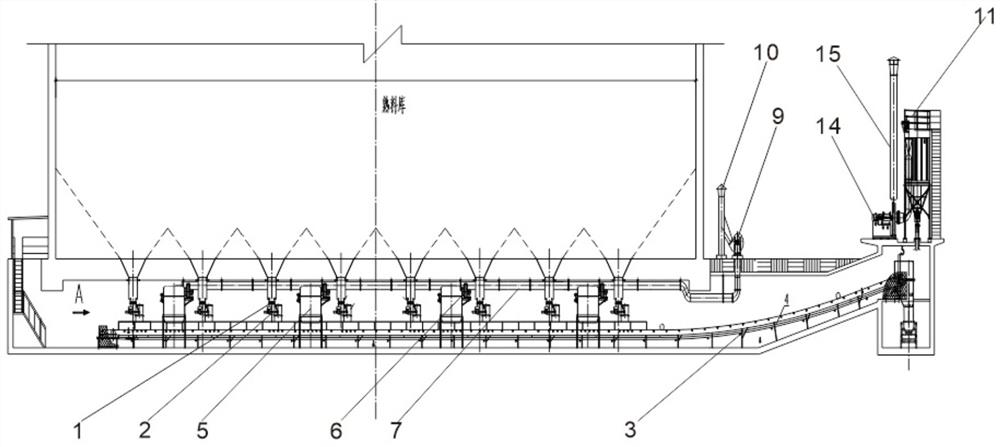

[0035] combined with Figure 1-9 A device for reducing dust at the bottom of the clinker silo, including three sets of clinker silo bottom unloading devices, conveying devices and dust collection devices; each set of clinker silo bottom unloading devices includes a Several rod gate valves 1 connected separately and electric arc gate valves 2 respectively connected with the rod gate valve 1; the conveying device includes three branch heat-resistant belt conveyors 3 and one summary heat-resistant belt conveyor 4, and the three branches are resistant to The thermal belt conveyors 3 are set corresponding to the three sets of clinker silo bottom unloading ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com