Spiral elevator

A screw elevator and hoist technology, applied in conveyor, loading/unloading, transportation and packaging, etc., can solve the problems of difficult cleaning, high labor intensity and high labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

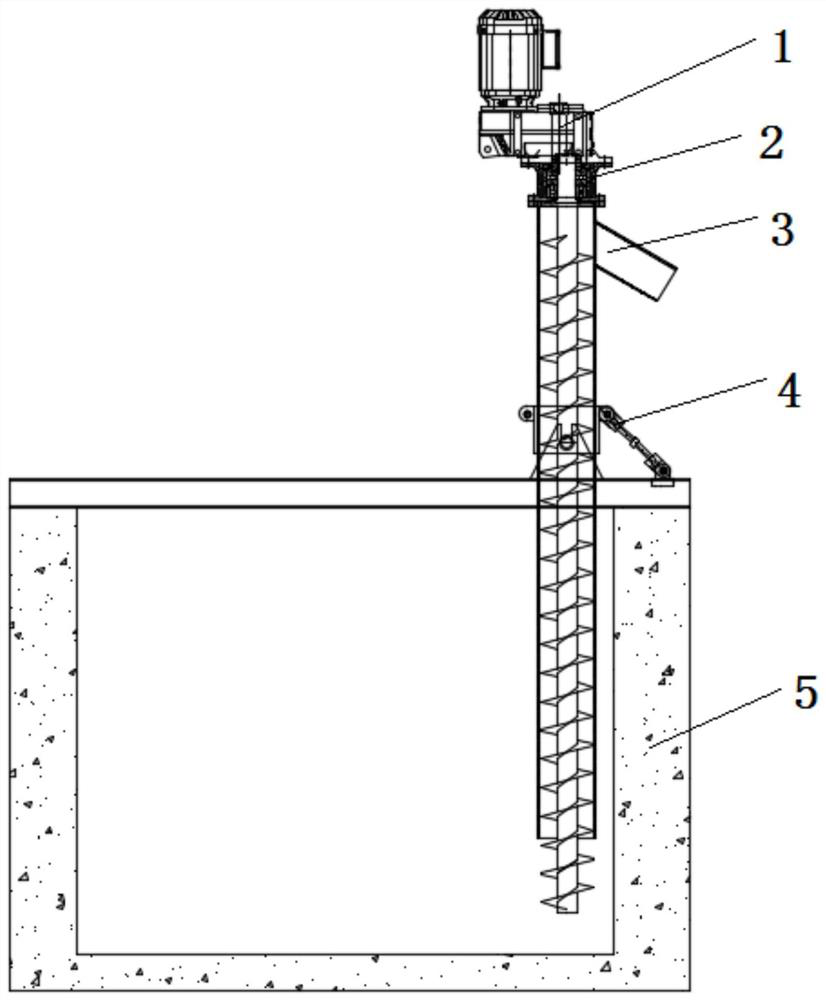

[0036] see Figure 1 to Figure 8 , a spiral hoist according to a preferred embodiment of the present invention, comprising a hoist body 3 and a mounting frame mechanism 4,

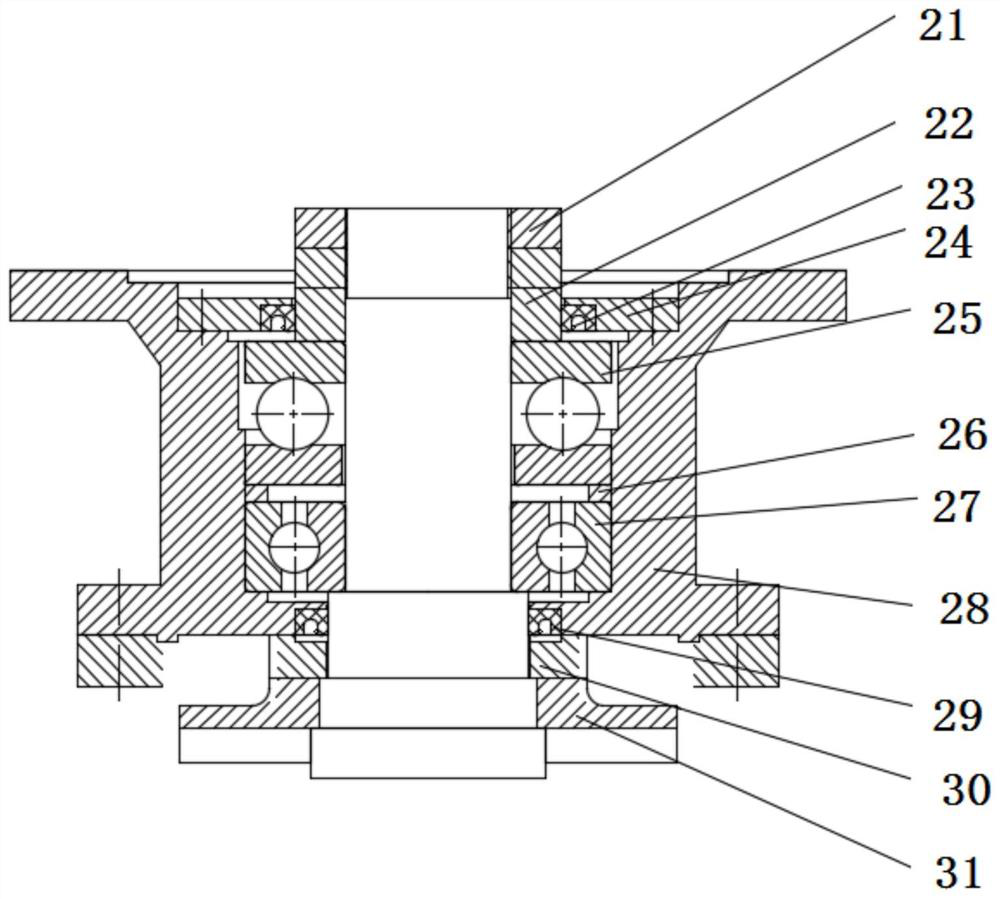

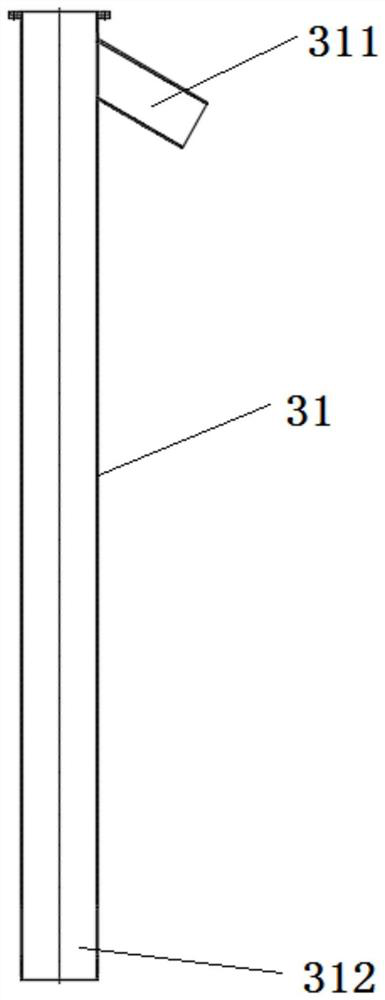

[0037] The hoist body 3 includes a cylinder body 31 and a shaft screw 32. The top of the hoist body 3 is connected to a fixed motor 1 through a screw shaft coupling mechanism 2. The motor 1 is a variable frequency motor, the model is DRE90L4 / C, and the power is 1.5kW, the output speed is 276rpm, by setting the frequency conversion motor 1, different speeds can be given according to the dryness and humidity of the bulk material, and the applicability is wider. The screw with shaft 32 includes a cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com