Material shoveling and loading conveyor

A technology of conveyors and belt conveyors, which is applied in the direction of conveyors, conveyor objects, loading/unloading, etc., and can solve problems such as tight space and inconvenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

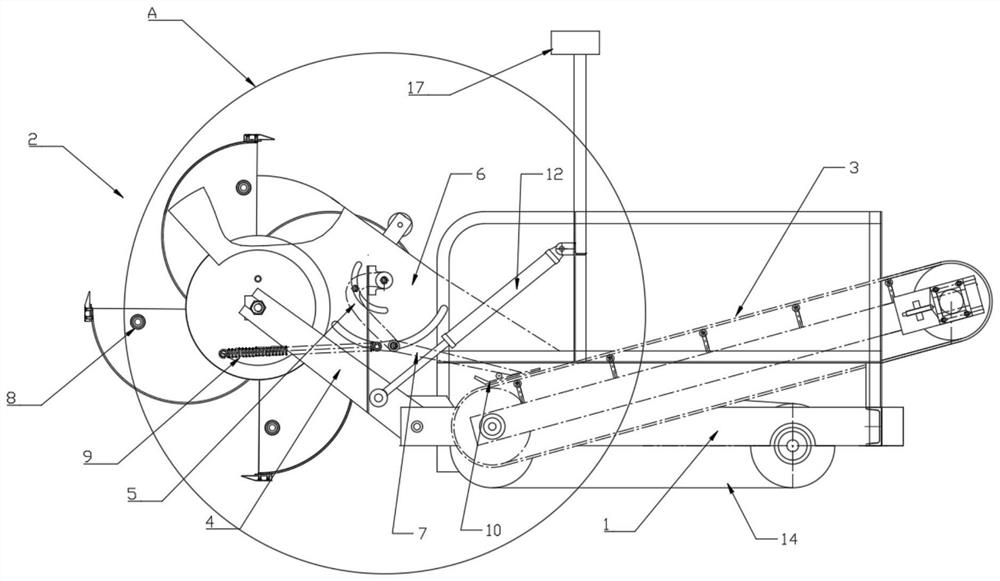

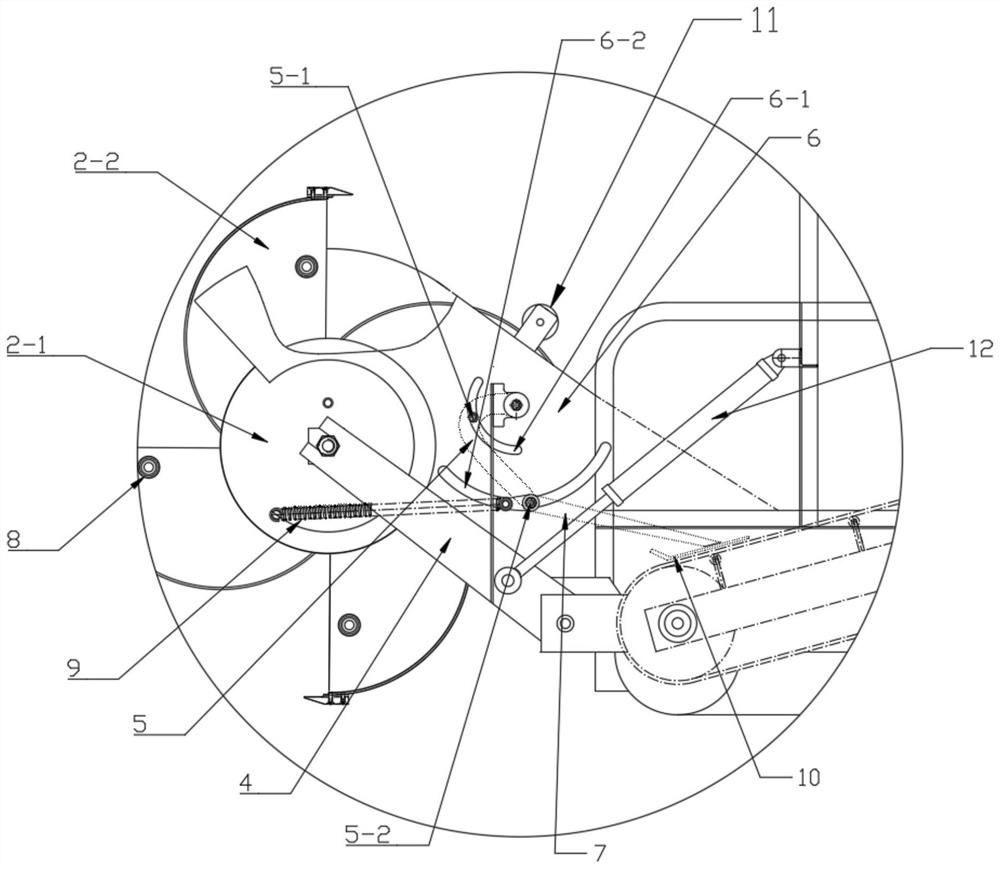

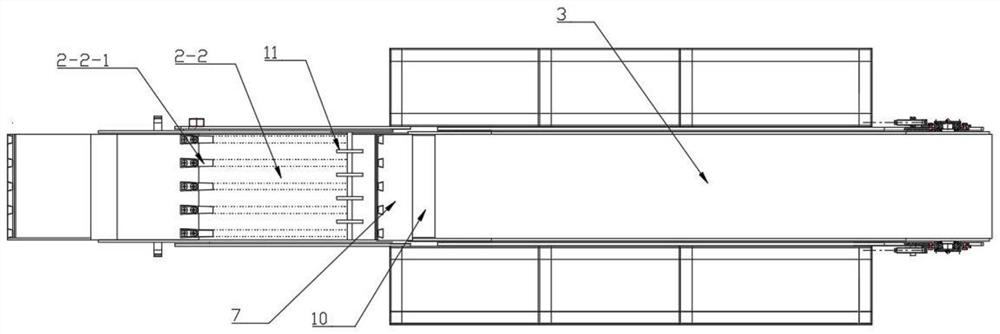

[0040] Please combine Figure 1-9 As shown, a material shovel conveyor includes a frame 1, a rotary bucket 2 and a belt conveyor 3, the belt conveyor 3 is installed on the frame 1, and the rotary bucket 2 passes through a pair of The support arm 4 is installed on the front end of the frame 1; the front end of the belt conveyor 3 is located at the rear and lower side of the rotary bucket 2, and the rear end is raised, and the rotary bucket 2 includes a drum 2-1 and a set The plurality of buckets 2-2 on the drum 2-1 also includes a traveling mechanism 14 on which the frame 1 is fixed, and the traveling mechanism is driven by a traveling hydraulic motor 14-1.

[0041] It also includes a curved boom 5, side plates 6 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com