In-situ chemical oxidation remediation monitoring and regulating system

An in-situ chemical oxidation and control system technology, applied in the field of in-situ chemical oxidation repair monitoring and control systems, can solve the problem of inability to achieve automatic monitoring and control, few monitoring parameters, and site engineers spending a lot of time on data collection and data processing, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

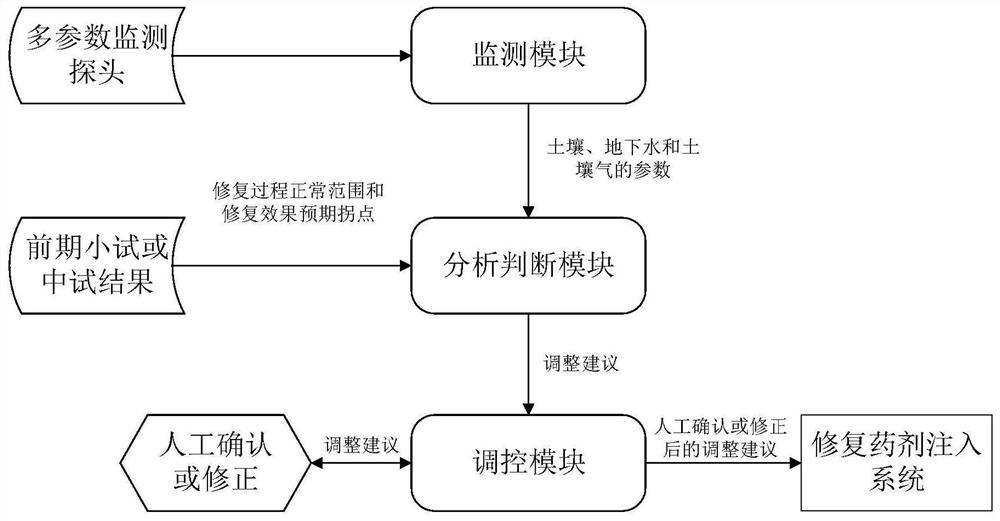

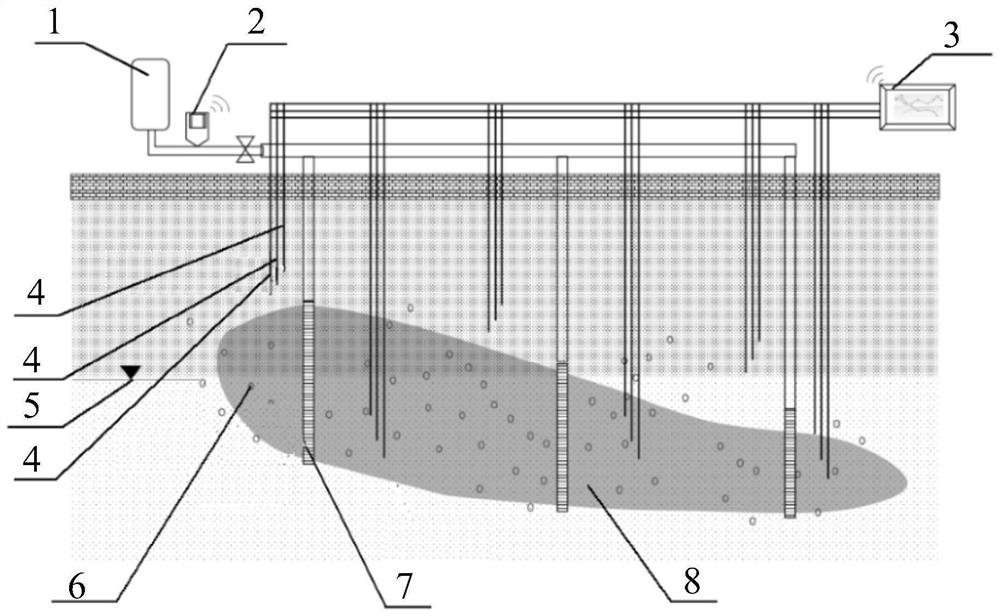

[0067] According to a specific embodiment of the present invention, the present invention provides an in-situ chemical oxidation repair monitoring and regulation system, comprising:

[0068] The monitoring module, in the process of in-situ chemical oxidation repair, automatically monitors the parameters in soil, groundwater and soil gas; the parameters in the monitored soil include: soil humidity, electrical conductivity and temperature; the parameters in the monitored groundwater Including: dissolved oxygen DO, temperature, pH value, conductivity, oxidation-reduction potential ORP, sulfate in groundwater; parameters in soil gas monitored include: CH in soil gas 4 , CO 2 concentration. These parameters are multi-parameter detections that can be realized by multi-parameter monitoring probes. Through multi-media and multi-parameter multi-evidence, the process of underground in-situ chemical reactions can be judged comprehensively.

[0069] Said parameters of automatic monitori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com