A Beaded PD-Ni Adsorbent for Deep Desulfurization of Refined Benzene

An adsorbent and bead-shaped technology, applied in the field of bead-shaped Pd-Ni adsorbent, can solve the problems of increased production cost, single mode of action, unfavorable high sulfur capacity and high selective adsorption, etc., and achieve orderly distribution and enhanced Force and selectivity, effect of improving adsorption performance and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] According to the Pd:Ni atomic ratio of 2:1, weigh 8 mg palladium acetylacetonate, 3.37 mg nickel acetylacetonate, 40 mg cetyltrimethylammonium chloride and 70 mg glucose into a beaker, and then pour 9 mL into the beaker Oleylamine solution, sealed with a sealing film, ultrasonic treatment for 30min, until a light yellow clear solution appeared in the beaker. Then transfer the beaker to the reaction kettle, seal it and put it into an oven, set the reaction temperature to 150° C., and the reaction time to 10 h. After the reaction is over, cool the reaction kettle to room temperature, pour the product in the reaction kettle into a centrifuge tube, and centrifuge for 13 minutes at 3500r / min, then pour the supernatant into the prepared solvent mixture solution (volume Cyclohexane and ethanol with a ratio of 1:7), shake and centrifuge again, repeat this step 3 times, collect the precipitate, and dry it at 55°C to obtain the product.

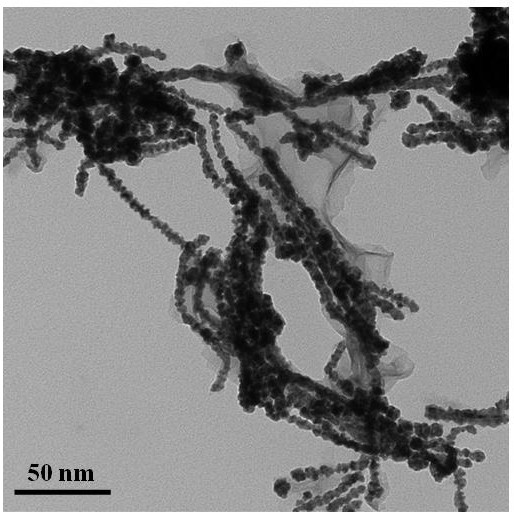

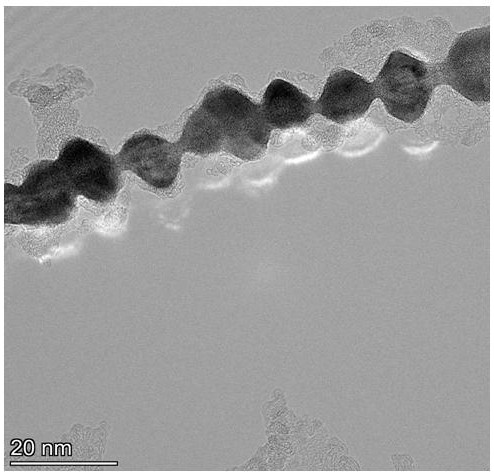

[0044] like figure 1 As shown, it can b...

Embodiment 2

[0047] According to the Pd:Ni atomic ratio of 2:1, correspondingly weigh 9.2mg of palladium acetylacetonate and 3.90mg of nickel acetylacetonate, 37mg of cetyltrimethylammonium chloride and 80mg of glucose into a beaker, and then pour into the beaker 9mL oleylamine solution, sealed with a sealing film, ultrasonic treatment for 30min, until a light yellow clear solution appeared in the beaker. Then transfer the beaker to the reaction kettle, seal it and put it into an oven, set the reaction temperature to 150°C, and the reaction time to 9.5h. After the reaction is over, cool the reaction kettle to room temperature, pour the product in the reaction kettle into a centrifuge tube, and centrifuge for 13 minutes at 3500r / min, then pour the supernatant into the prepared solvent mixture solution (volume Cyclohexane and ethanol with a ratio of 1:7), shake and centrifuge again, repeat this step 3 times, collect the precipitate, and dry it at 70°C to obtain the product.

Embodiment 3

[0049] According to the Pd:Ni atomic ratio of 1:1, correspondingly weigh 8.55mg of palladium acetylacetonate and 6.45mg of nickel acetylacetonate, 40mg of cetyltrimethylammonium chloride and 90mg of glucose in a beaker, and then pour into the beaker 8.5mL oleylamine solution, sealed with a sealing film, ultrasonic treatment for 35min, until a light yellow clear solution appeared in the beaker. Then transfer the beaker to the reaction kettle, seal it and put it into an oven, set the reaction temperature to 170° C., and the reaction time to 8.5 hours. After the reaction is over, cool the reaction kettle to room temperature, pour the product in the reaction kettle into a centrifuge tube, and centrifuge for 12 minutes at 3500r / min, then pour the supernatant into the prepared solvent mixture solution (volume Cyclohexane and ethanol with a ratio of 1:9), shake and centrifuge again, repeat this step 5 times, collect the precipitate, and dry it at 65°C to obtain the product.

[0050]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com