Sedimentation tank for sewage treatment

A technology of sewage treatment and sedimentation tank, which is applied in the direction of sedimentation separation, settling tank, chemical/physical process, etc., and can solve the problems of not having sewage and chemical mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

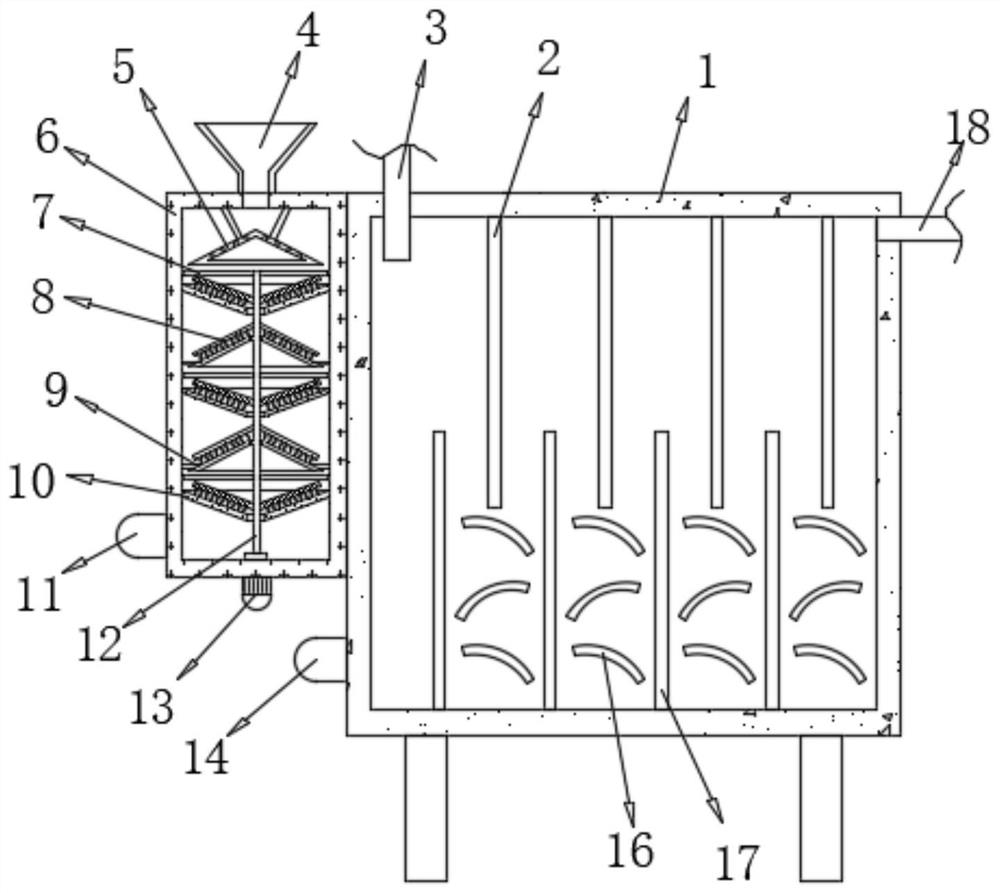

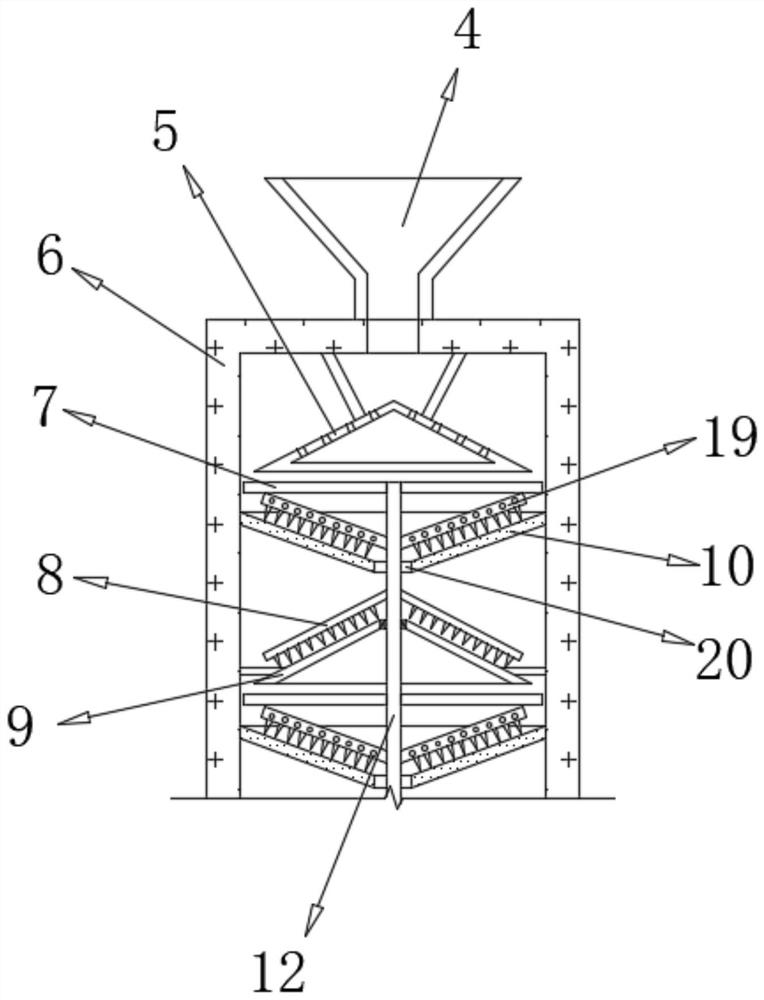

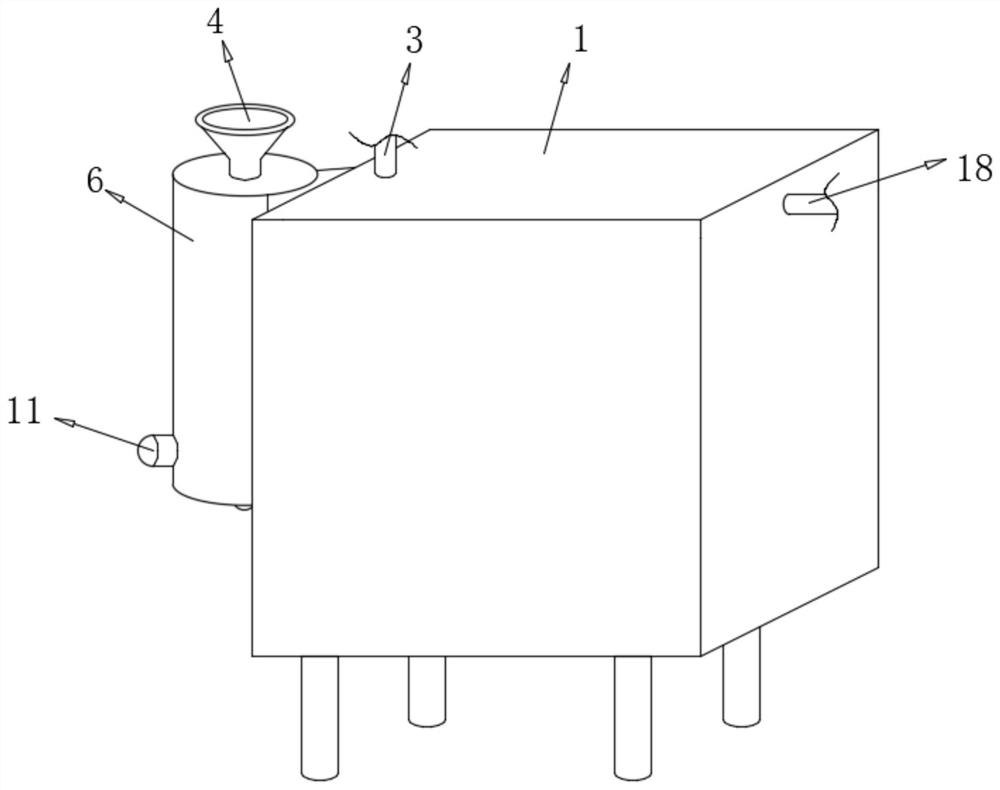

[0028] refer to Figure 1-3 , a sedimentation tank for sewage treatment, comprising a sedimentation tank body 1, a mixing shell 6 is connected to one side of the outer wall of the sedimentation tank body 1 through fastening bolts, and the top outer wall of the mixing shell 6 is connected to a feeding material through fastening bolts Funnel 4, the top inner wall of the mixing shell 6 is connected with a discharge box 5 of conical structure by fastening bolts, and the circumference of the top outer wall of the discharge box 5 is provided with evenly distributed discharge ports, and the inner wall of the mixing shell 6 circumference Transition funnels 10 and deflectors 9 are alternately connected by fastening bolts, and there is a gap between the bottom of the circumference of the deflectors 9 and the circumferential inner wall of the mixing shell 6, the transition funnel 10 is a funnel-shaped structure, and the deflectors 9 is a conical structure, and the center of the outer wal...

Embodiment 2

[0039] refer to Figure 4 , a sedimentation tank for sewage treatment. Compared with Embodiment 1, this embodiment has fixed rods 15 evenly distributed on the side of the bottom inner wall of the sedimentation tank body 1 close to the feeding pipe 3 through fastening bolts, and the fixed rods 15 There are evenly distributed barbs 21 connected by fastening bolts at the circumference of each.

[0040] Working principle: the fixed rod 15 and the barb 21 buffer the loaded sewage to ensure timely and effective calm of the sewage, and the barb 21 prevents the sediment from being washed away by the loaded sewage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com