Frame fan system with single profile

A profile and frame fan technology, which is applied in the layout of wing fan, the installation of window glass, switches with brakes, etc., can solve the problems of inconvenient installation, many types of materials, and high design and production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

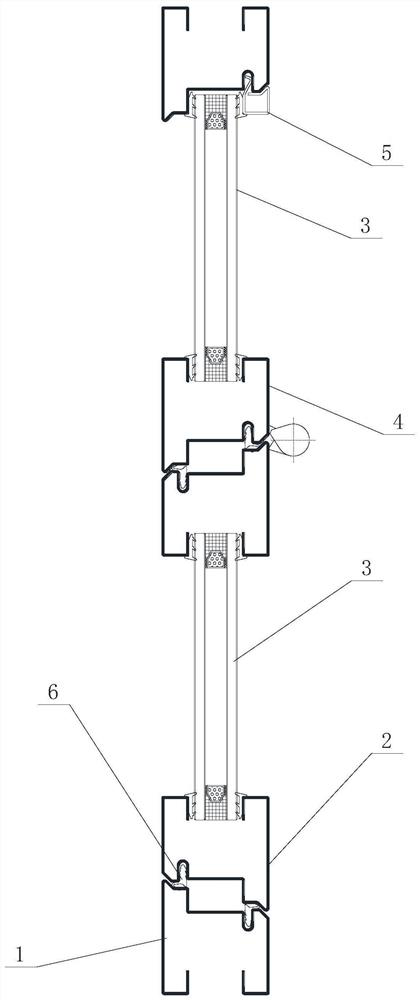

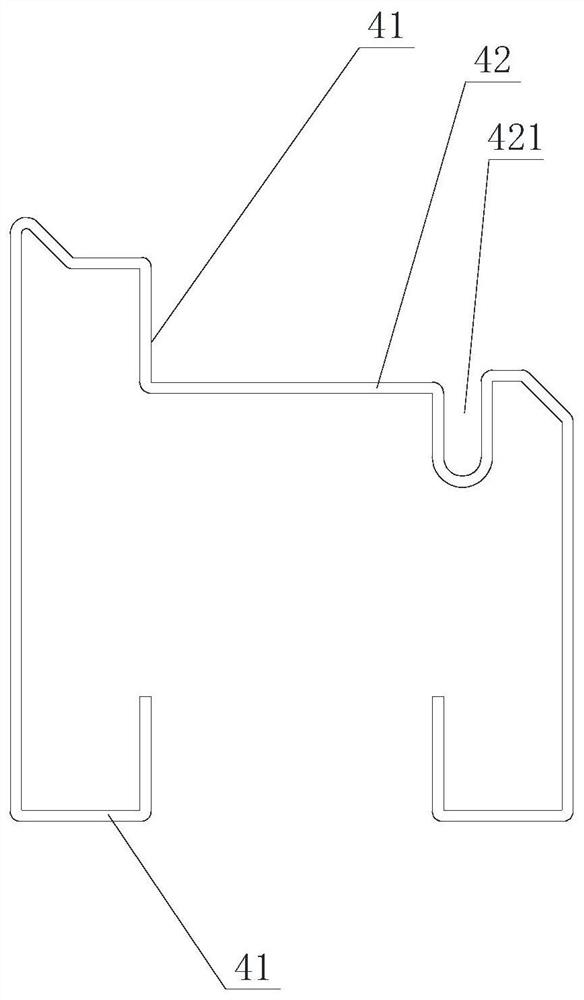

[0028] figure 1 with figure 2 It shows the first embodiment of the frame and fan system of a single profile of the present invention, the frame and fan system includes a fixed frame 1, a fan frame 2 and a glass 3, the fan frame 2 is hinged with the fixed frame 1, and the glass 3 is installed on the fan frame 2 and installed in the fixed frame 1 without opening function, the fixed frame 1 and the fan frame 2 are all assembled by the profile 4 of the present embodiment, and the profile 4 includes at least one extended edge 41 and for Connect the connecting side 42 of the extended side 41, the connecting side 42 is provided with a sinking groove 421, and also includes a bead 5, and the beading 5 is installed on the sinking groove 421 of the fan frame 2 and / or the fixed frame 1 without opening function and cooperates to extend The side 41 clamps the glass 3 , and the sinker groove 421 of the fixed frame 1 and the fan frame 2 is provided with a rubber strip 6 for sealing. During...

Embodiment 2

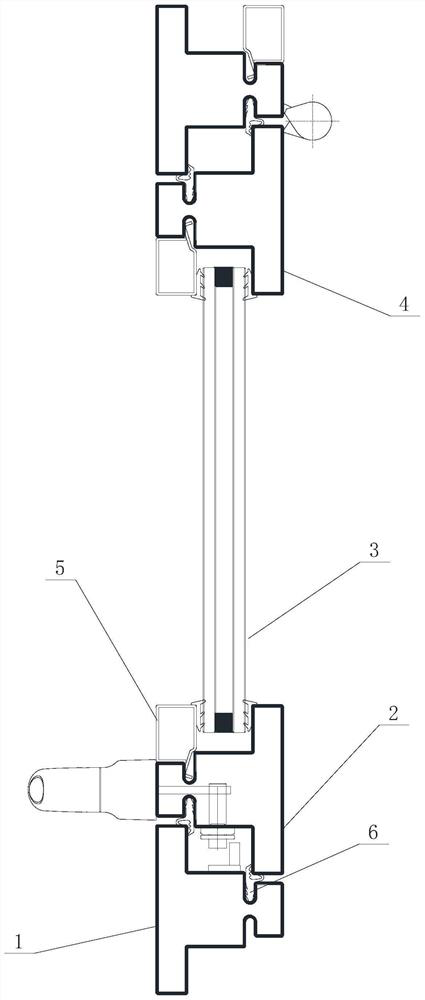

[0034] image 3 with Figure 4 It shows the second embodiment of the frame fan system of a single profile of the present invention, the frame fan system is basically the same as Embodiment 1, the only difference is: in this embodiment, the sinking groove 421 divides the connecting edge 42 into two sections, The connecting edge 42 of the upper section and the lower section is dislocated, and the connecting edge 42 of the lower section and the end of the extension edge 41 are located on the same straight line. This arrangement makes the lower connecting side 42 of the fixed frame 1 and the extended side 41 of the fan frame 2 on the same straight line, which can prevent the fan frame 2 from closing and over-positioning while ensuring the sealing effect.

[0035] In this embodiment, the profile 4 is arranged as a T-shaped structure, and the profile 4 of the T-shaped structure includes a pair of extended sides 41 located on opposite sides and the same side, and the glass 3 is pres...

Embodiment 3

[0037] Figure 5with Image 6 Shows the third embodiment of the frame fan system of a single profile of the present invention, the frame fan system is basically the same as Embodiment 1, the only difference is: in this embodiment, the profile 4 is set as a Z-shaped structure, and the Z-shaped structure The profile 4 includes a pair of extended sides 41 located on opposite sides and opposite sides. The glass 3 is pressed on the extended sides 41 in the fan frame 2 and the fixed frame 1 without opening function and cooperates with the bead 5 on the sinker 421 to form a clip. Hold, the extended side 41 of the corresponding side in the fan frame 2 is in sealing contact with the rubber strip 6 in the corresponding side sink groove 421 of the fixed frame 1, and the extended side 41 of the corresponding side in the fixed frame 1 is in contact with the corresponding side sink groove 421 of the fan frame 2 The rubber strip 6 seals the contact. The frames of the frame fan system are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com