Prefabricated safety learning exploration hall and installation method thereof

A prefabricated and safe technology, applied in the field of safety, can solve the problems of boring learning, failure to meet safety training, and difficulty in obtaining personal experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

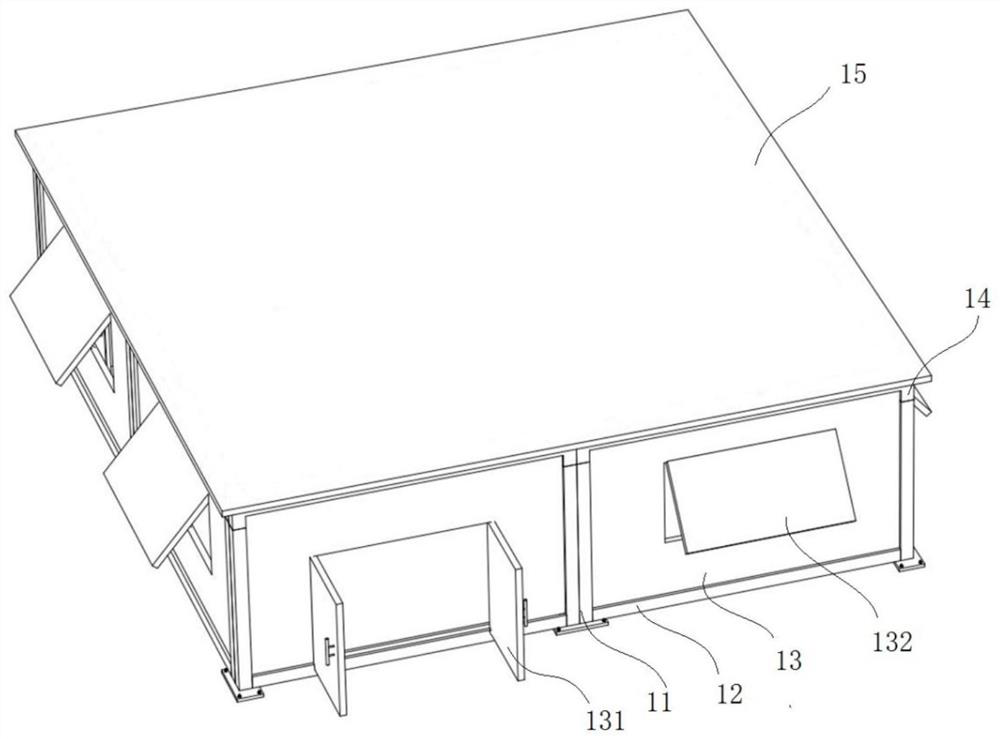

[0091] For a prefabricated and assembled safety learning experience hall provided in this embodiment, refer to figure 1 , comprising a house building and at least one safety experience area arranged in the house building; the house building is a single-storey house building; Body of wall 13; The column 11 is vertically arranged on the ground; The two ends of the body of wall 13 are respectively mortised and jointed with the sides of two adjacent columns 11; 11 mortise joint; the lower end surface of the top beam 14 is tenon jointed with the wall 13; the lower end surface of the floor 15 is tenon jointed with the upper end surface of the top beam 14 and / or connected by fasteners; at least one A door 131 is disposed on the wall body 13 .

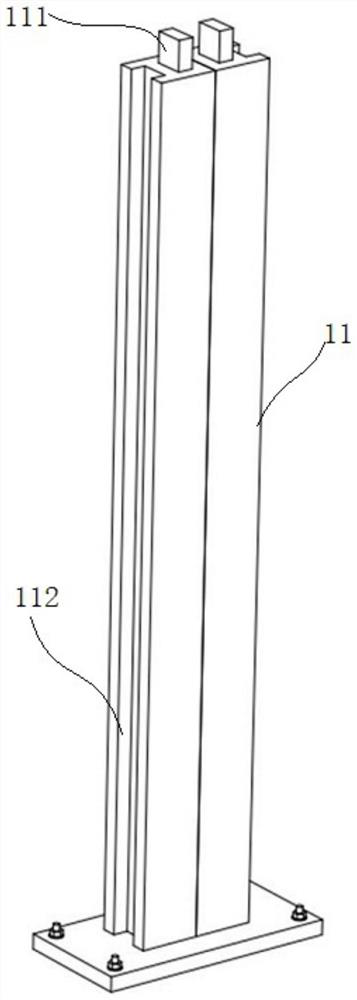

[0092] The columns 11 each include a column body and at least two column tenons 111 arranged at one end of the column body; at least two column tenon grooves 112 located on different sides are provided on the sides of the column body; the flo...

Embodiment 2

[0108]On the basis of Embodiment 1, this embodiment is also provided with wall panels and roof beams 14 in the building, and the wall formed by the columns 11, wall panels and roof beams 14 divides the interior of the building into two or With more than two housing spaces, multiple safety experience items are set in different housing spaces to reduce mutual interference during the safety experience process of multiple groups of construction workers.

[0109] It should be noted that the column 11 includes a first column with three column tenons 111 at one end of the column and three column tenons 112 on different sides on the side of the column, two column tenons 111 at one end of the column, and The side of the body is provided with two second columns with column mortise 112 located on different sides; if the building is divided into four or more housing spaces arranged in a matrix, the column 11 also includes a column set at one end. There are four post tenons 111 and four po...

Embodiment 3

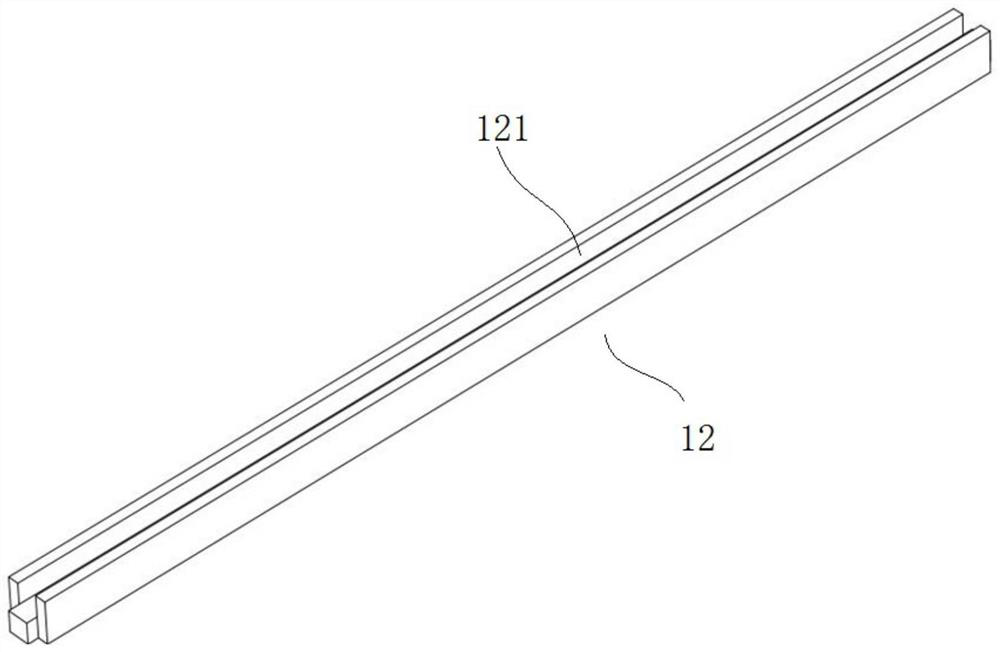

[0121] On the basis of the above-mentioned embodiment 1 or 2, the prefabricated part of this embodiment also includes a bottom beam 12; refer to image 3 , the two ends of the bottom beam 12 are mortised with the column 11 respectively; When the body of wall 13 is installed between two adjacent columns 11, the lower end and the bottom beam 12 are mortised and tenoned through the bottom mortise 121, so that the walls 13 are connected to the columns 11, the bottom beam 12 and the top beam 14 respectively. Form a mortise joint to achieve a stable overall structure of the building wall.

[0122] When the house building is provided with the bottom beam 12, refer to Figure 6-9 , the installation method of the safety learning experience hall is as follows:

[0123] S1: Assembling housing construction;

[0124] S11: Prepare prefabricated parts, including multiple columns 11, multiple roof beams 14, multiple bottom beams 12, at least one floor slab 15 and multiple walls 13;

[012...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com