Prefabricated structure for supporting slope

A prefabricated structure and slope technology, which is applied in basic structure engineering, coastline protection, excavation, etc., can solve the problems of high cost and long construction period, and achieve the effects of convenient operation, reduced construction cost and convenient transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

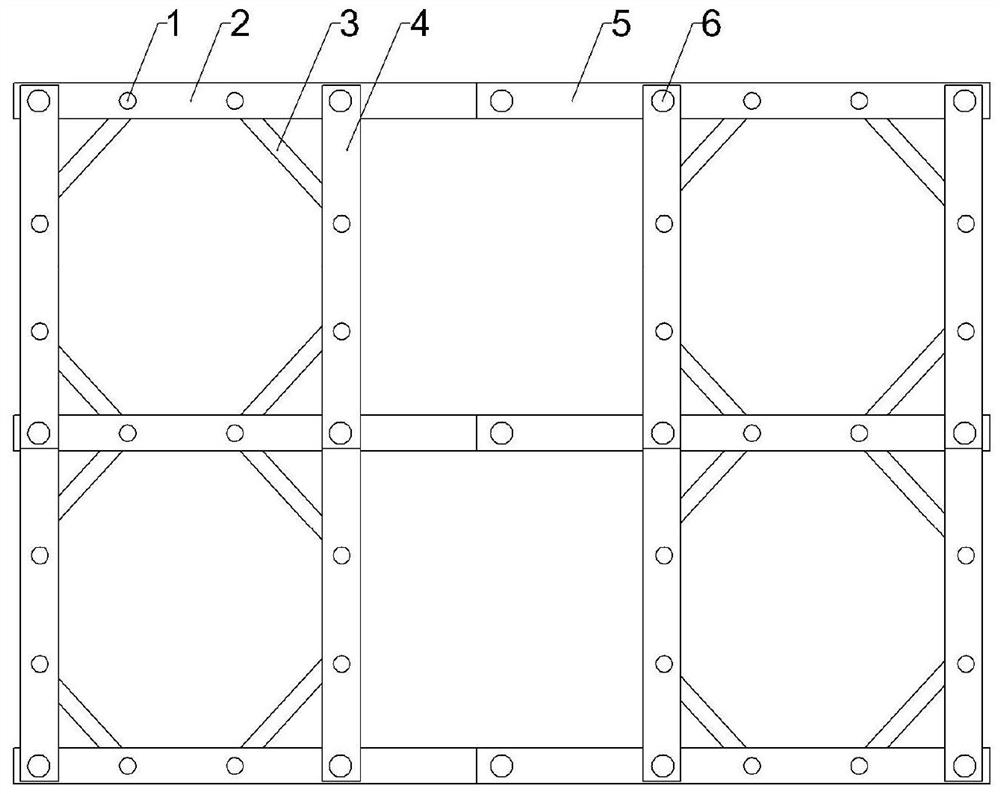

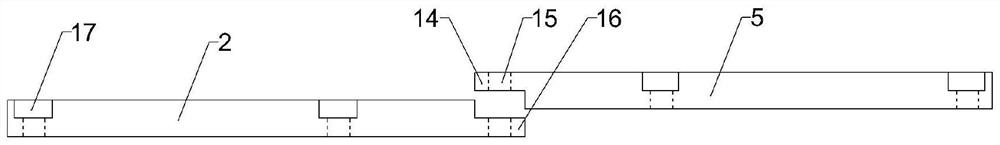

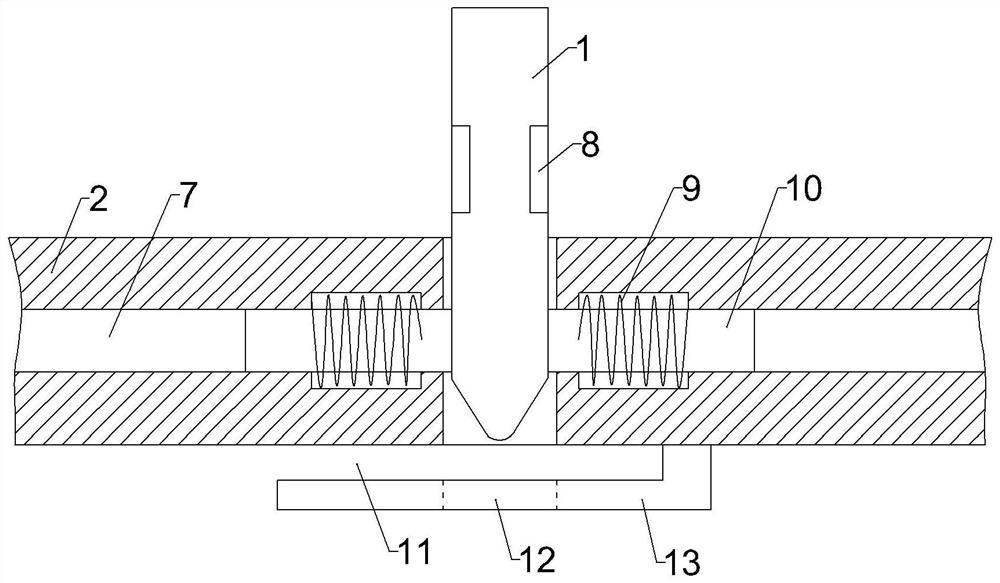

[0024] like figure 1 As shown, a prefabricated structure for supporting a slope includes prefabricated beams and longitudinal beams 4 , which are assembled to form a lattice beam, and the joints of the beams and longitudinal beams 4 are anchored by anchor rods 6 . Specifically, the crossbeam includes a left crossbeam 2 and a right crossbeam 5, combined with figure 2 It can be seen that the right end of the left crossbeam 2 is integrally formed with a lower connecting plate 16, and the left end of the right crossbeam 5 is integrally formed with an upper connecting plate 14, and the lower connecting plate 16 and the upper connecting plate 14 are provided with an anchor rod hole 15 for connecting the anchor rod 6. After the upper connecting plate 14 is buckled on the lower connecting plate 16, the anchor holes 15 of the two are aligned, and the anchor rod 6 passes through the anchor holes 15 of the two to realize the assembling of the left beam 2 and the right beam 5.

[0025] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com