Cross hinge type electric spark micro inverted cone hole machining mechanism

A technology of cross hinge and processing mechanism, which is applied in the field of cross hinge EDM fine reverse taper hole processing mechanism, which can solve the problems of impossible stable position of cone top, influence of hole size, low processing precision of reverse taper hole, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

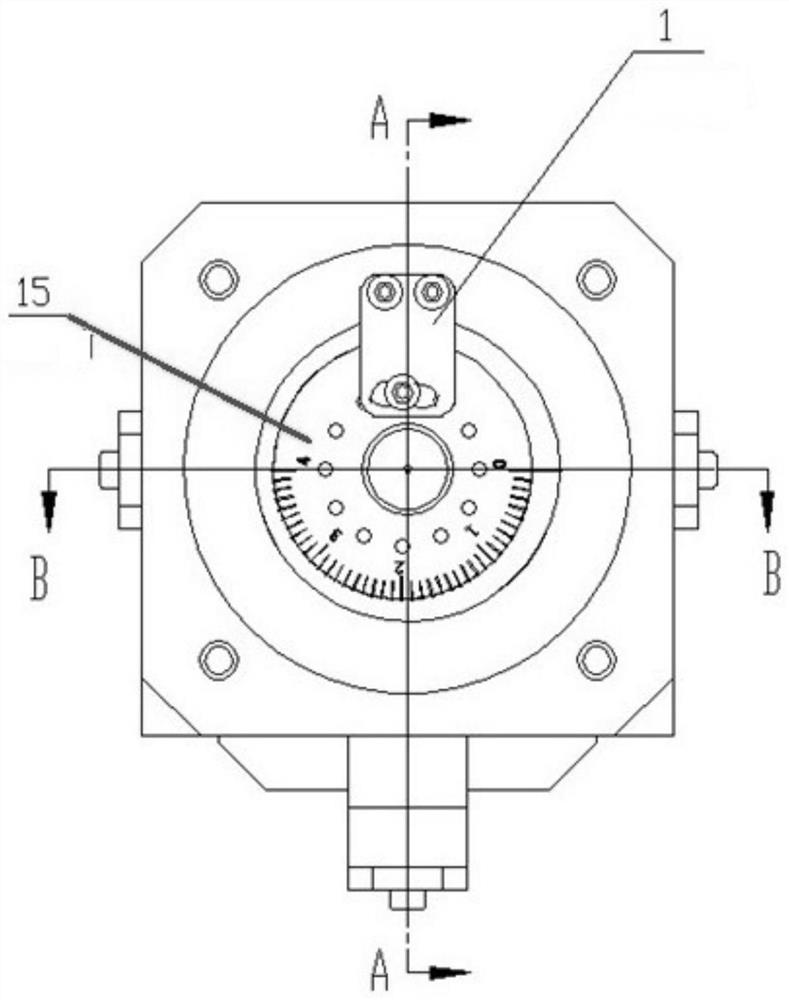

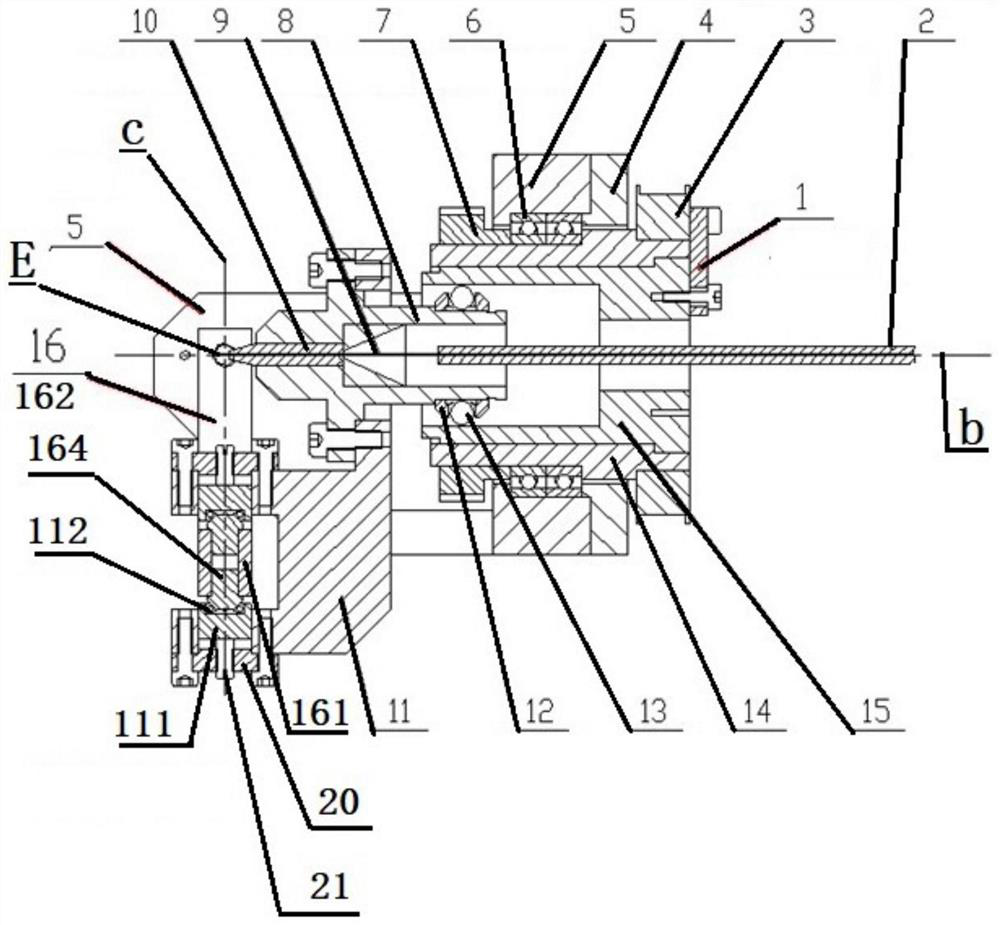

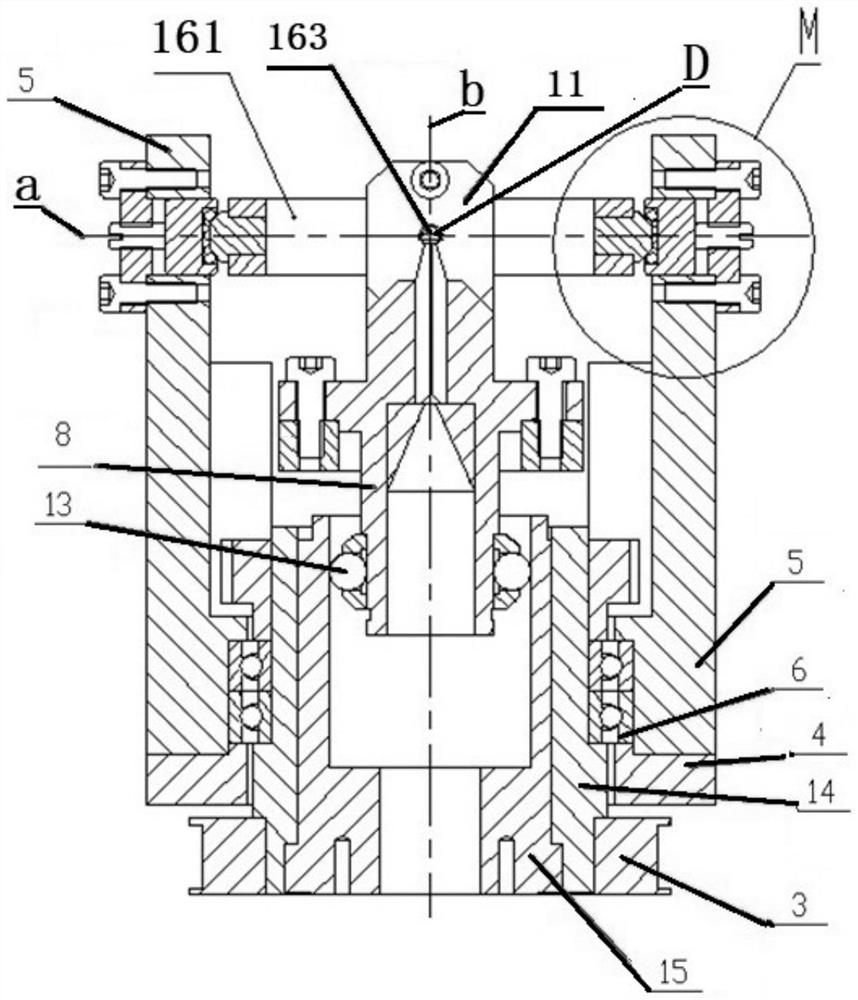

[0031] Such as Figure 1 to Figure 3 and Figure 5 As shown, a cross-hinged electric spark micro-inverted taper hole machining mechanism includes: a frame 5, a bearing hole is provided on the frame 5, and a thin-walled bearing 6 is installed in the bearing hole of the frame 5 through the bearing The gland 4 presses against the outer ring of the thin-walled bearing 6, and the bearing gland 4 is fixed to the frame. Thin-walled bearings are thin-walled bearings. Here, thin-walled bearings are used to achieve extremely thin bearing sections. The use of thin-walled bearings in the present invention can achieve product miniaturization and light weight. Take the shaft diameter of 25mm as an example. The outer diameter of the contact ball bearing is 52mm, and the outer diameter of the thin-walled bearing is only 32mm.

[0032] A rotating shaft 14 is installed on the inner ring of the thin-walled bearing, and the inner ring of the thin-walled bearing 6 is fixed by a lock nut 7. The rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com