A shrinkable wet bag cold isostatic pressing mold

A technology for cold isostatic pressing and forming molds, applied in other manufacturing equipment/tools, turbines, engine components, etc., to solve problems affecting dimensional accuracy and straightness, bar bending, bar size, and straightness differences , to ensure stability, improve concentricity, and ensure the effect of straightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

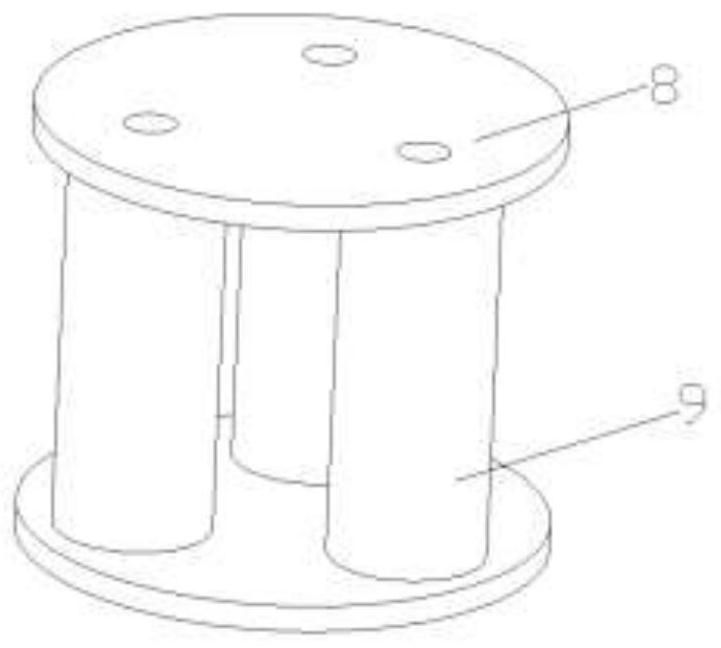

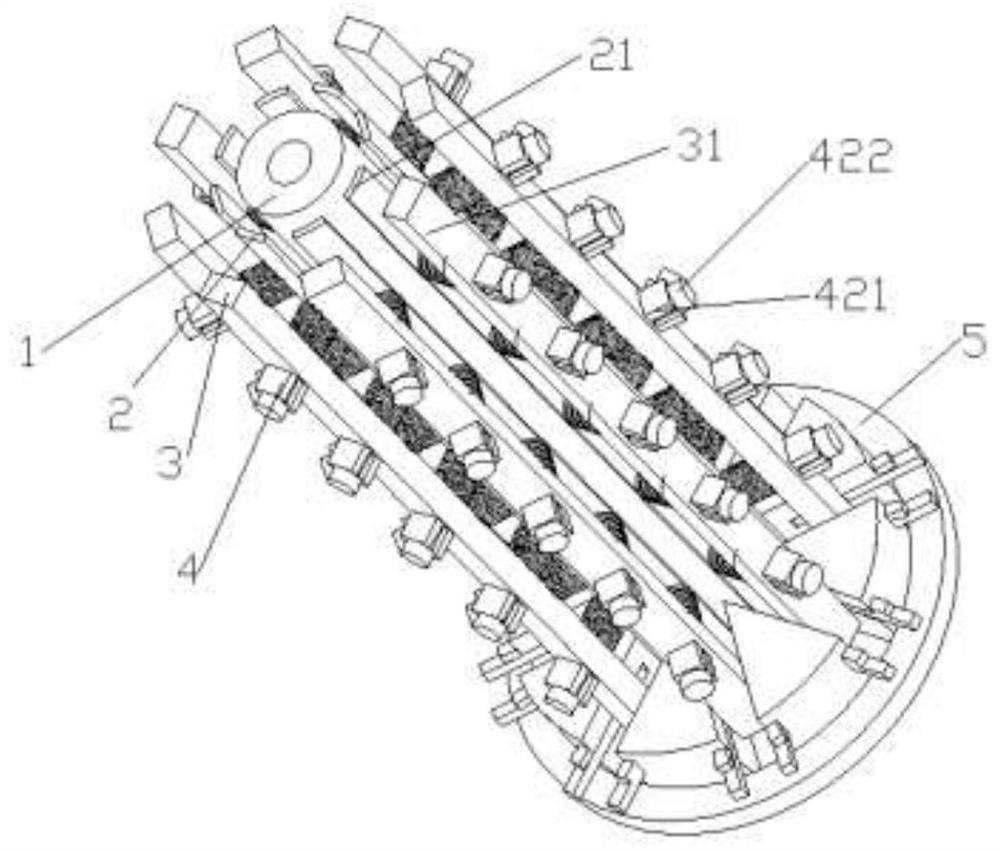

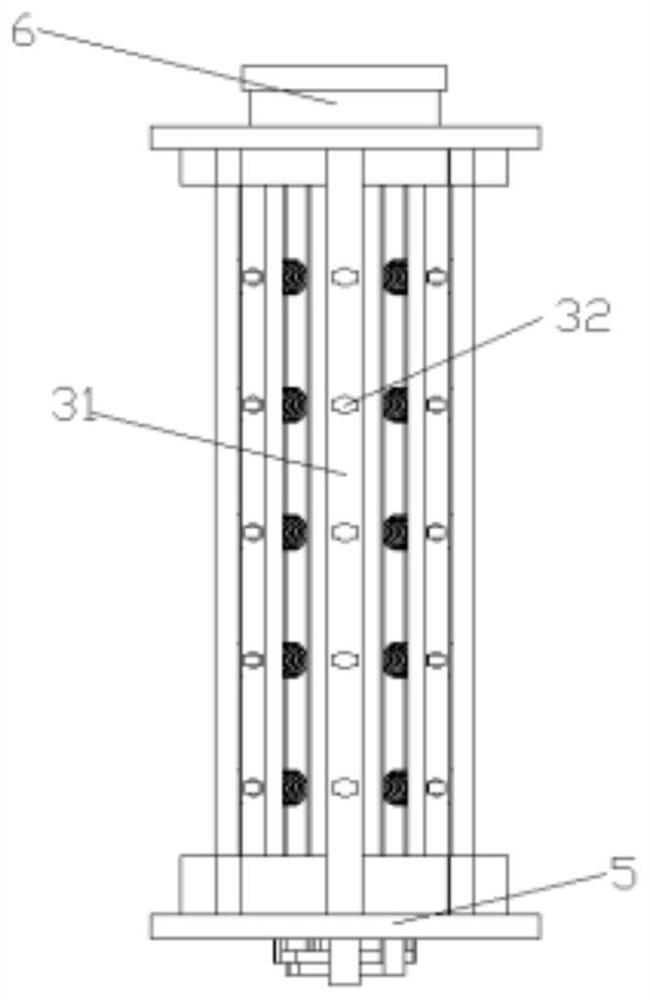

[0025] Embodiment 1: as figure 1 , figure 2 , image 3 Shown, a kind of shrinkable wet bag type cold isostatic pressing molding die comprises support frame 8, and 3 molding dies 9 that are movably arranged on the support frame; The flexible mold 1 is arranged around the flexible mold 1 and can shrink together with the support plate 21 of the flexible mold 1, and the steel sheath fixture 3 arranged on the periphery of the support plate 21 is arranged on the steel sheath fixture 3 for The support plate 21 provides the elastic device 4 of elastic force, which is arranged below the steel sheath fixing device 3 and is used to support the bottom support device 5 of the steel sheath fixing device 3, and is arranged above the steel sheath fixing device 3 and can be placed into a flexible mold The top support device 6 of 1; there are 2×4 support plates 21, and the 2×4 support plates 21 are evenly arranged circumferentially about the central axis of the flexible mold 1 to form a stee...

Embodiment 2

[0031] Embodiment 2: as Figure 8 , Figure 9 As shown, the difference from Embodiment 1 is that an interlocking device 7 is provided under the steel sheath 2; the interlocking device 7 includes a gear shaft 71 arranged below the bottom plate 51 and coaxial with the flexible mold 1, and arranged on the gear shaft Four follower gears 73 on 71 correspond to the interlocking rack device 72 arranged below the support plate 21 ; the interlocking rack device 72 can mesh with the follower gear 73 .

[0032] Such as Figure 10 As shown, the driven gear 73 includes four first gears 731 , and the four first gears 731 can mesh with the four interlocking rack devices 72 one by one.

Embodiment 3

[0033] Embodiment 3: The difference from Embodiment 2 is that the follower gear 73 adopts a second gear, and the second gear adopts a gear columnar structure, and the four interlocking rack devices 72 mesh with the second gear sequentially from top to bottom.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com