planter

A planter and rack technology, applied in the field of agricultural machinery, can solve the problems of uneven rice seed sowing, soreness in the waist and legs, and production efficiency, and achieve the effects of solving uneven sowing, avoiding bending, and reducing workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

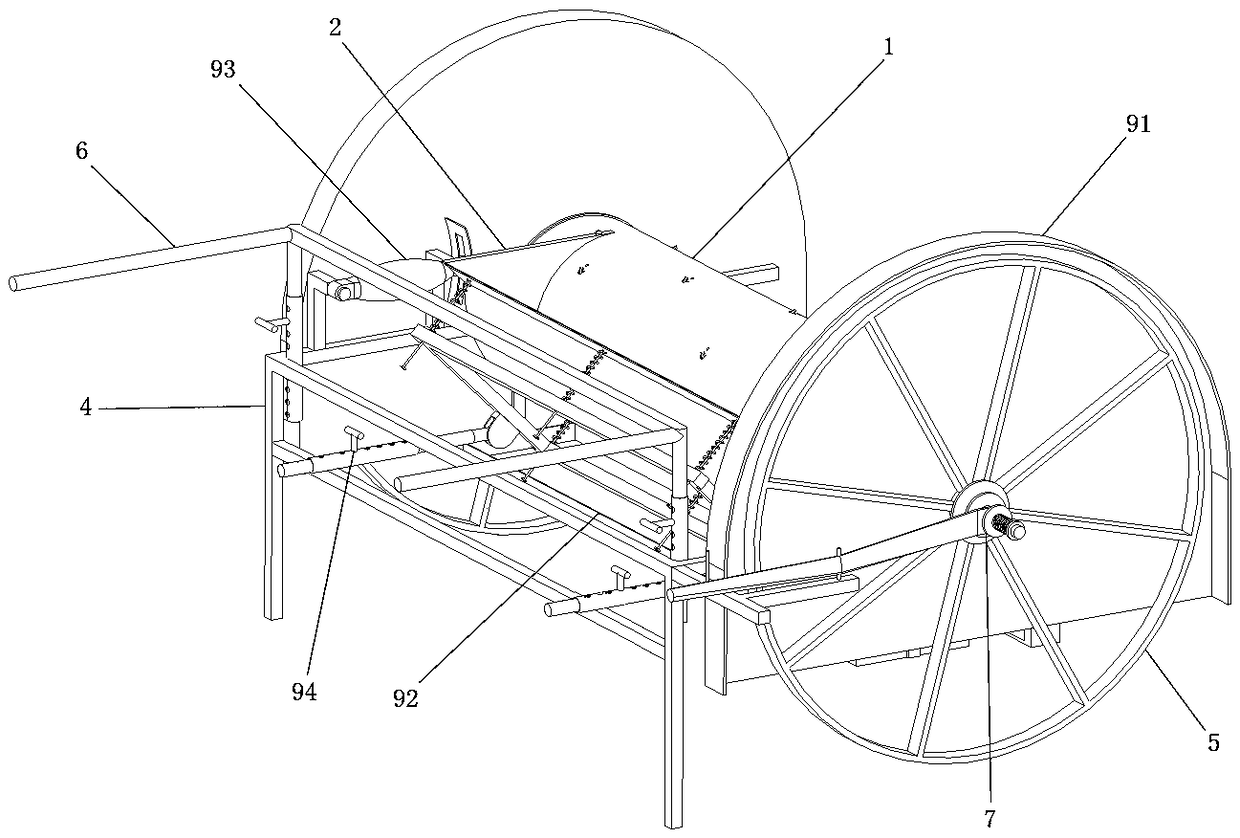

[0040] Such as Figure 1~3 Shown, a kind of planter comprises frame 4, walking wheel 5, handle 6, rotating shaft 3, clutch device 7, cylinder 1, four-wheel bucket 2, funnel 8, waterproof cover 91, collection tray 92 and blister ruler 93. The rear of frame 4 is installed handle 6 by fixing rotating rod 94, makes the height of handle 6 adjustable. Bearing blocks 95 are arranged on the left and right sides of frame 4, and one-way bearings with grooves are arranged in the bearing blocks 95, and rotating shaft 3 is installed in the one-way bearings with grooves; Turn in only one direction, forward. Rotating shaft 3 also passes cylinder 1, connects the road wheel 5 on the left side by clutch device 7 at the left end of rotating shaft 3, connects the road wheel 5 on the right side by common bearing at the right end of rotating shaft 3. At the rear of the drum 1, the four-wheeled bucket 2 is rollingly connected with the drum 1; at the front and bottom of the drum 1, a row of funnels...

Embodiment 2

[0052] Based on Example 1, such as Figure 16~19 As shown, make the following changes:

[0053] 1) The number of fixed disks 12 is changed to fifteen;

[0054] 2) The number of tongue spoons 11 on each fixed plate 12 is changed to seven;

[0055] 3) Increase the size of the funnel 8, and change the distance between the centers of two adjacent funnels 8 to 17 cm;

[0056] 4) Every three fixed disks 12 are close to each other to form a group, and each group of fixed disks 12 is aligned with a funnel 8; the distance between each group of fixed disks 12 is changed to 17 cm;

[0057] 5) The frame 4, the handle 6, the four-wheel bucket 2, the rotating shaft 3, the drum wall 13, and the funnel frame 801 are adjusted accordingly.

[0058] In this way, when sowing, the seeds scooped up by the three tongue spoons 11 are poured into the same funnel in sequence, and the number of seeds falling to the ground increases. The distance between the centers of two adjacent funnels 8 increase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com