Processing device applied to rivet connection of shock absorber

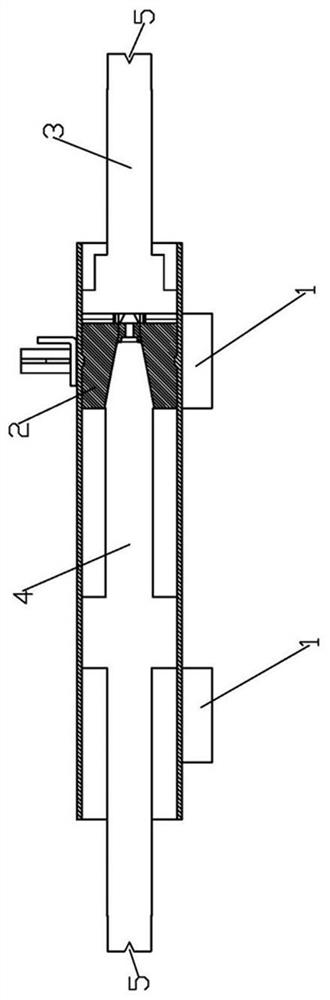

A technology of riveting device and shock absorber, which is applied in the field of riveting, and can solve problems such as cumbersome operation process, incompetence of flat molds, frequent replacement of mold positions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

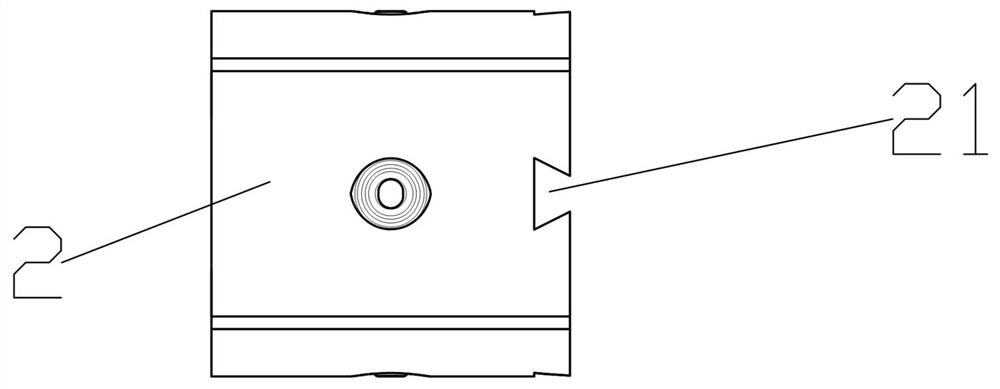

[0042] Riveting of the hose support:

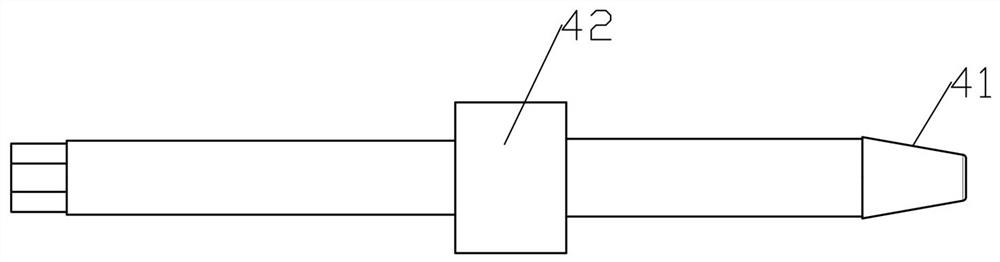

[0043] (1) Place two supporting bases, one of which is placed directly under the punch of the riveting machine, and the other base is 200mm away from it, and the two bases are mechanically fixed; the oil storage cylinder is placed flat on the supporting base, and the axial position is adjusted , place the part to be riveted directly under the punch of the riveting machine; put the mold containing 4 fan-shaped die pieces into the pipeline of the oil storage tube, use the first positioning component to axially position it to the place to be riveted, and pass through the first A positioning component rotates the mold group so that the mold groove is aligned with the position to be riveted; the hose bracket and the blank holder for placing the rivet are positioned at the position to be riveted, and the punch of the riveting machine is positioned at the blank holder.

[0044] (2) Insert the second positioning assembly from the other side of th...

Embodiment 2

[0047] Riveting of spring disks:

[0048] (1) Place three supporting bases, place the oil storage tank flat on the base, adjust the position of the bases so that one of the bases is in the center of the tank, and the other two are at 30mm from both ends of the tank, and mechanically fix the bases; Put the spring disk on the oil cylinder, adjust the position of the spring disk, and align the part of the spring disk to be riveted with the punch; put the mold containing 8 dies into the oil storage tube, and use the first positioning component to axially position it to The position to be riveted, and rotate the mold so that the mold groove is aligned with the position to be riveted; the spring plate and the blank holder for placing the rivet are positioned at the position to be riveted, and the punch of the riveting machine is aligned with the blank holder.

[0049] (2) Insert the second positioning device from the other side of the oil storage tube pipe. When the female guiding s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com