Special self-locking core axle clamp for processing eyepiece seat of laser distance measuring instrument

A technology of laser distance measurement and instrument eyepiece, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of surface finish and processing accuracy not meeting the requirements of drawings, inconvenient loading and unloading of workpieces, and discounts in processing quality, etc. , to achieve the effect of convenient and fast loading and unloading of workpieces, simplified structure and high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

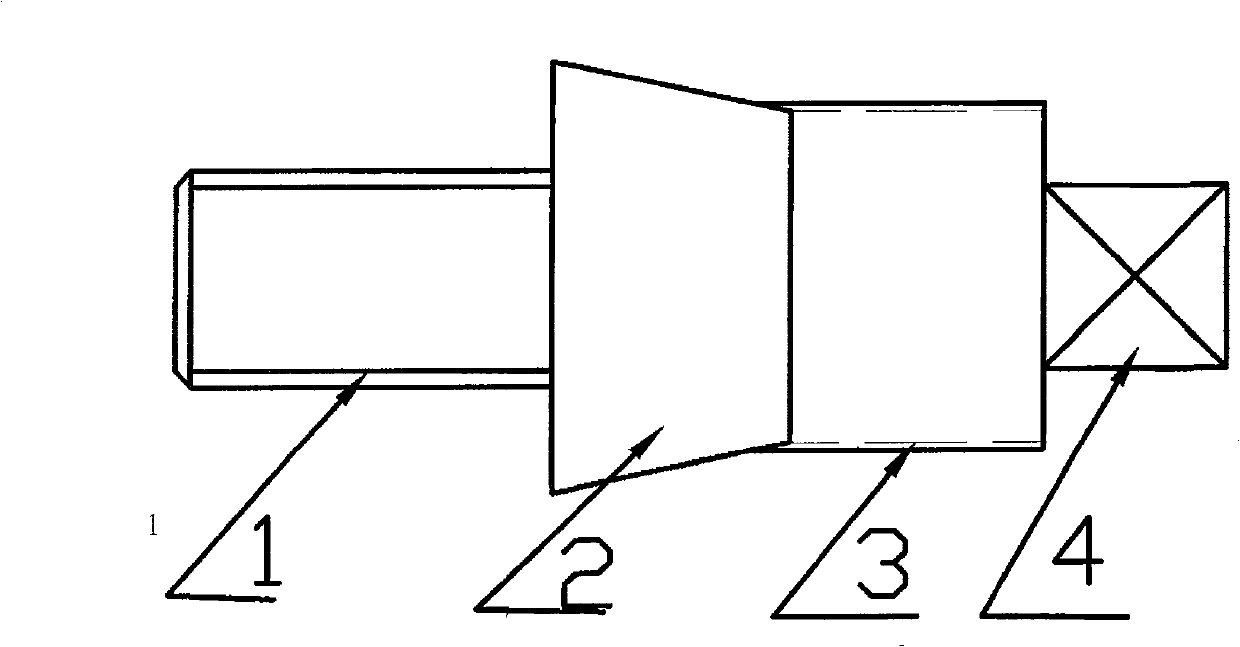

[0013] like image 3 As shown, this is a self-locking cone, (from left to right) the external thread 1 at the front end is on the protruding cylinder, followed by the internal cone 2, then the external thread 3, and finally the flattened part 4.

[0014] like Figure 4 As shown, this is a cone seat structure, (from left to right) the front end is a cylinder 5, followed by an outer cone 6, which has a sunken circular hole, and the internal thread 7 is arranged on the circular hole, and the external A cylindrical step 8 is set at the left end of the cone 6 .

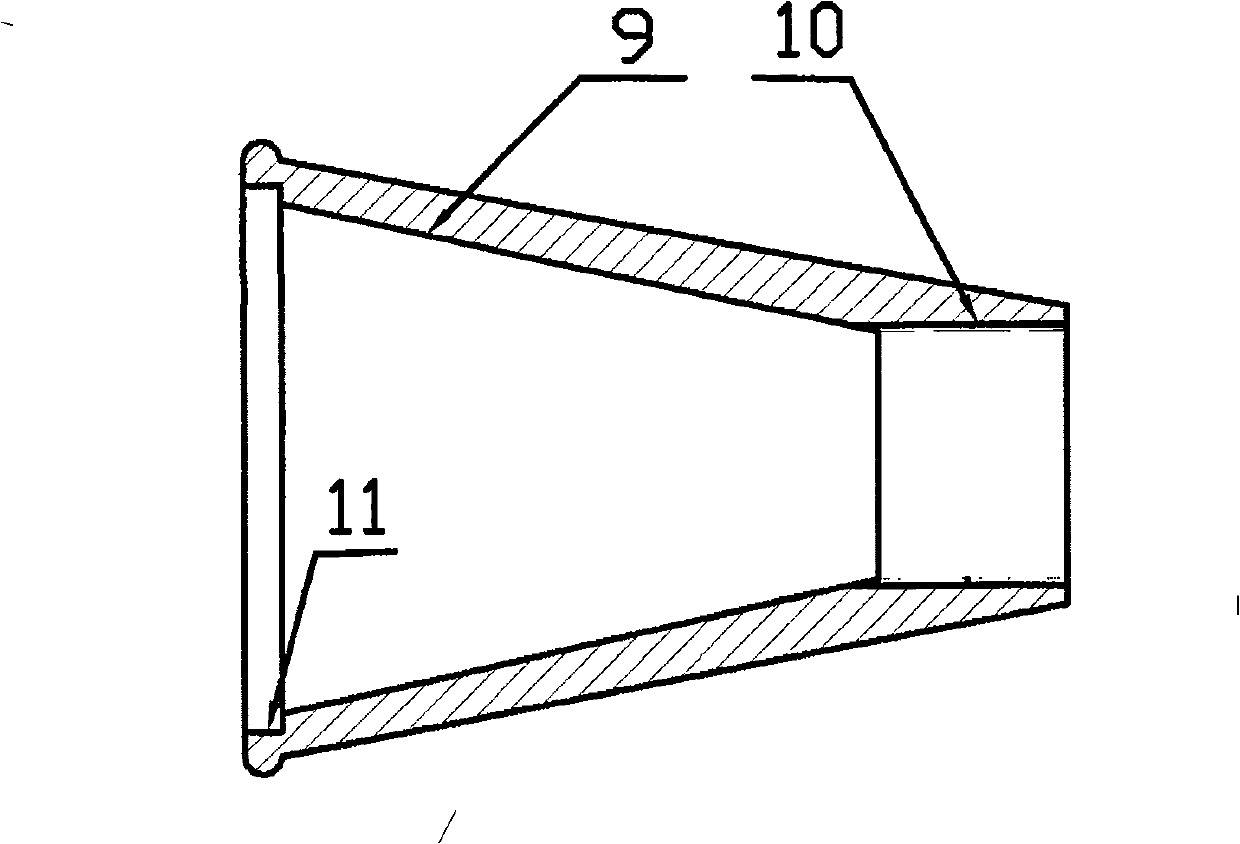

[0015] like figure 2 As shown, this is the structure of the workpiece to be processed, (from left to right) an inner step 11 is set at the wide part of the cone part 9, and the rear part is a cylindrical internal thread 10.

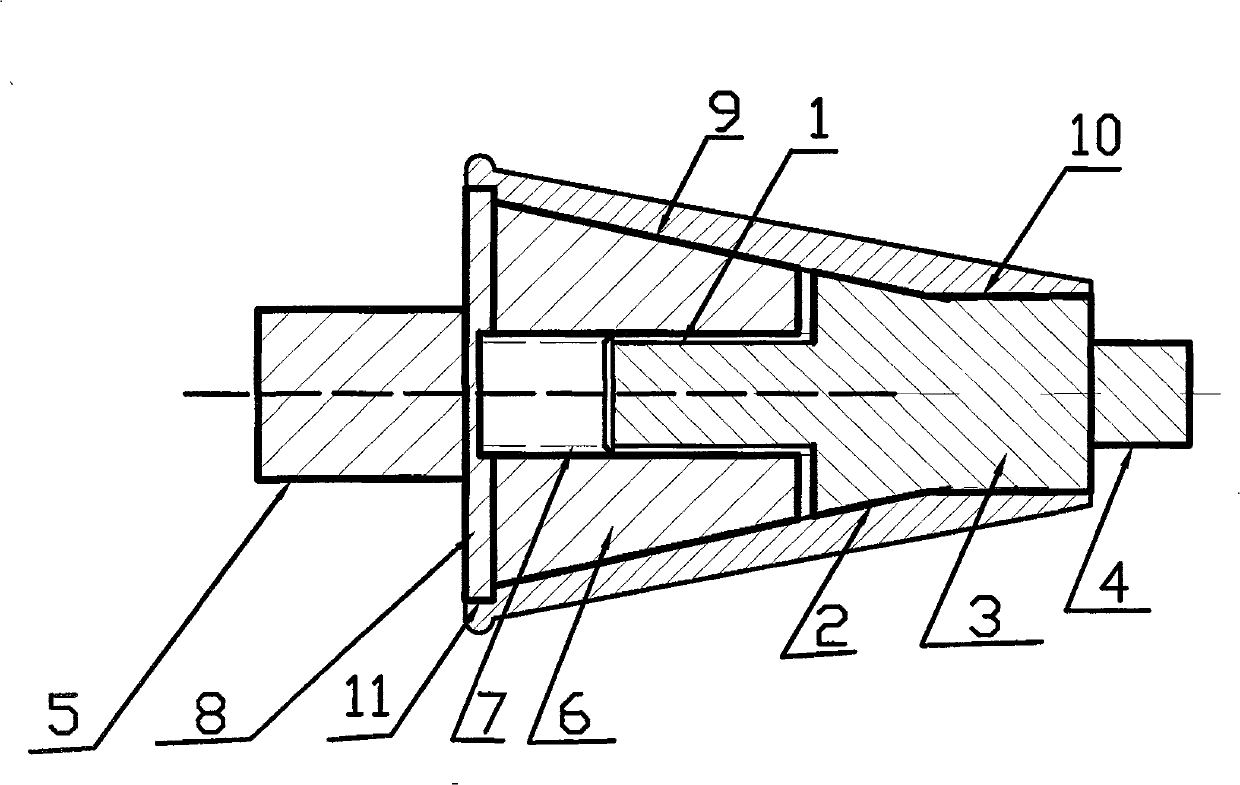

[0016] like figure 1 As shown, the fixture is composed of a cone seat and a self-locking cone. The external thread 1 protruding from the front end of the cylinder on the self-locking cone is inse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com