Cleaning device for solar photovoltaic panel and cleaning method of solar photovoltaic panel

A technology for a solar photovoltaic panel and a cleaning device, which is applied in the field of solar power generation, can solve the problems of damage to the solar photovoltaic panel, poor cleaning effect, and laborious device driving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

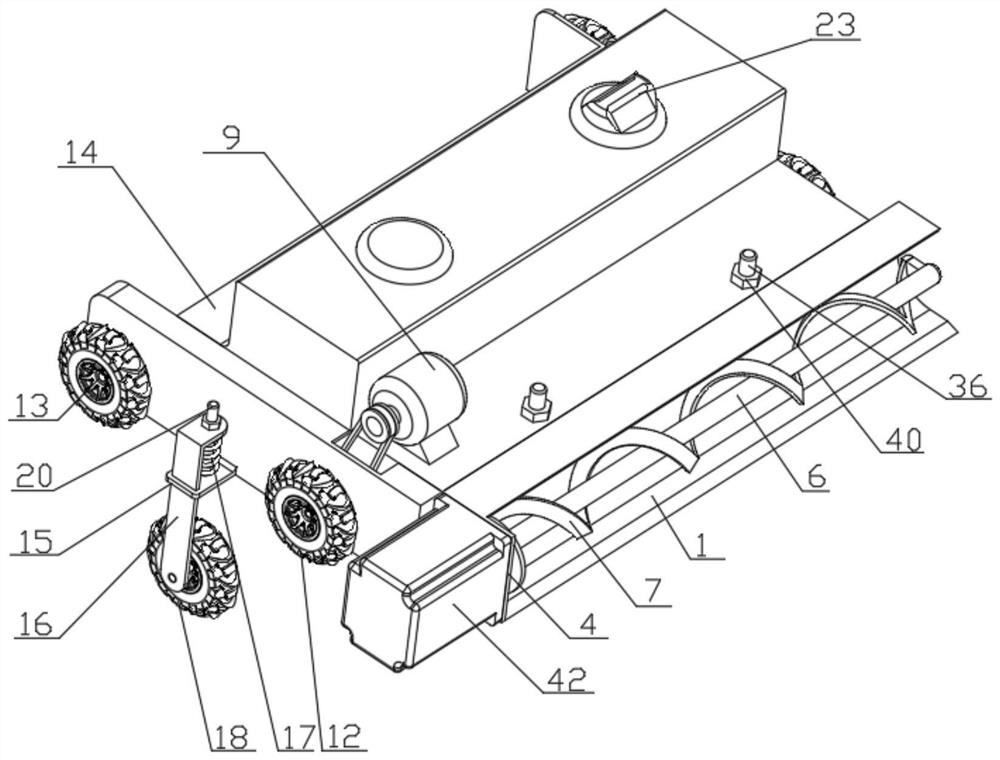

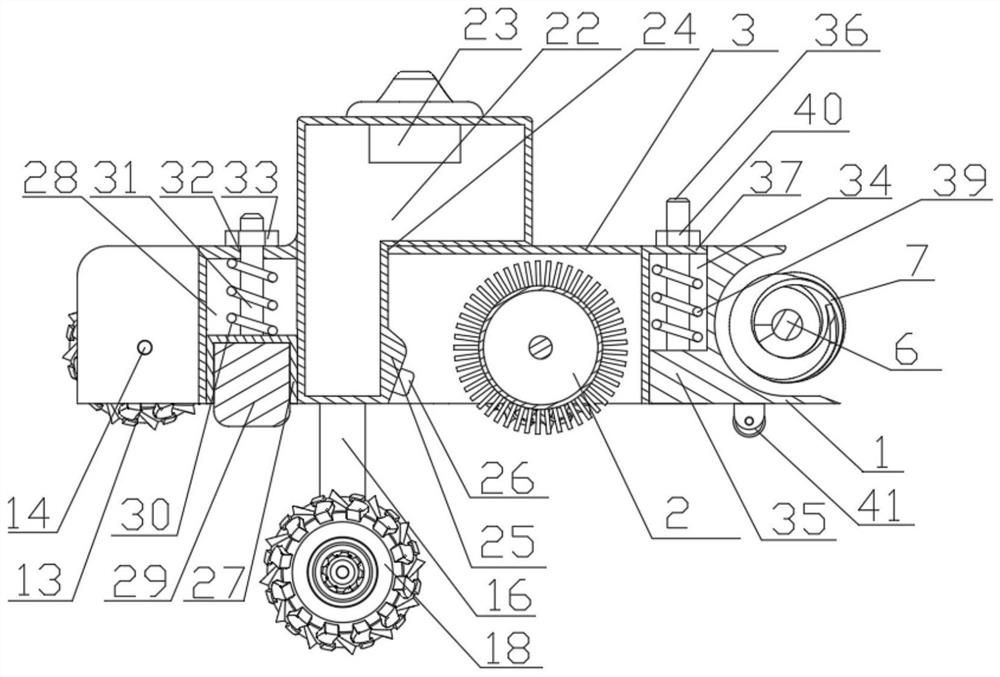

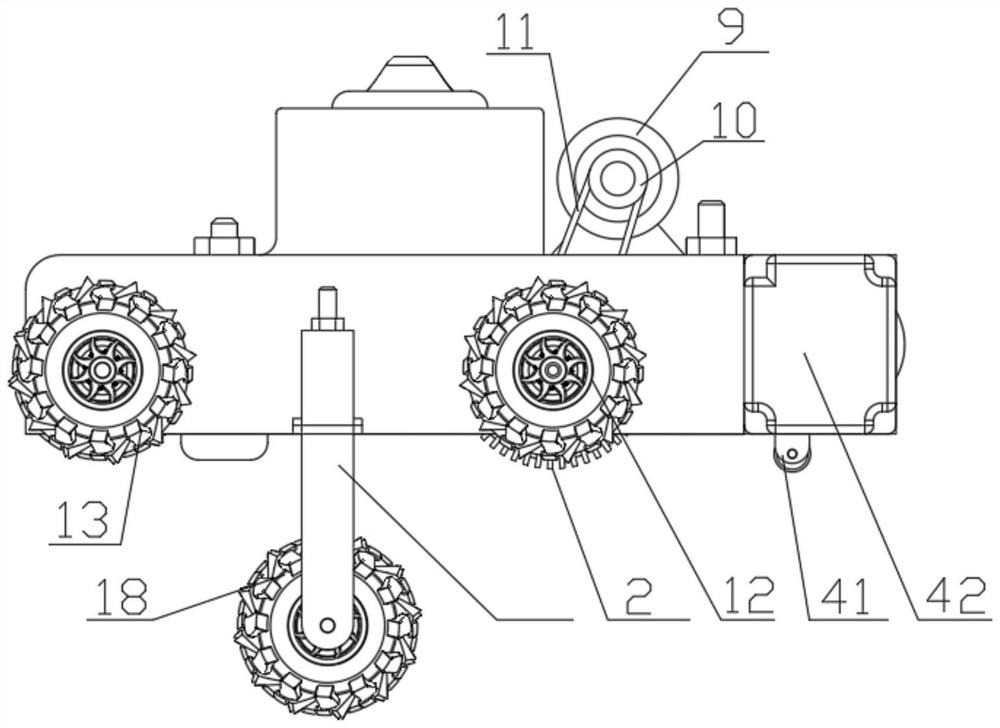

[0042] Such as Figure 1-7 As shown, a cleaning device for solar photovoltaic panels includes a shovel plate 1, a cleaning roller 2, a housing 3, a snow guide assembly, a walking device, a transmission assembly and a power device, and the housing 3 is a box with an open bottom One end of the housing 3 is provided with a guide groove 34, one end of the shovel plate 1 is in an arc-shaped structure, and the other end is provided with a slider 35 that cooperates with the guide groove 34, and the top of the slider 35 A second connecting rod 36 is provided, a top plate 37 is provided on the top of the guide groove 34, a fourth through hole 38 is arranged on the top plate 37, and the end of the second connecting rod 36 passes through the fourth through hole 38 The shovel plate 1 is installed in the guide groove 34, and the shovel plate 1 can move along the axis direction of the guide groove 34, the second connecting rod 36 is sleeved with a third spring 39, and the third spring 39 T...

Embodiment 2

[0044] Such as Figure 1-7 As shown, this embodiment is basically the same as Embodiment 1, the difference is that the snow guide assembly includes a rotating shaft 6 and a guide vane 7, the guide vane 7 has a spiral structure, and the two ends of the guide vane 7 are respectively fixed On the rotating shaft 6 , the end of the rotating shaft 6 passes through the first through hole 5 to place the snow guide assembly in the blade 1 , and the rotating shaft 6 can rotate along its own axis. Also include guard plate 8, described power unit comprises first motor 9 and second motor 42, and described transmission assembly comprises belt pulley 10 and transmission belt 11, and one end of described cleaning roller 2, on the output shaft of first motor 9 all A pulley 10 is provided, the transmission belt 11 is wound on the pulley 10, the rotation of the first motor 9 can drive the rotation of the cleaning roller 2, and the second motor 42 is arranged on the end plate 4, so The output sh...

Embodiment 3

[0046] Such as Figure 1-7As shown, this embodiment is basically the same as Embodiment 2, the difference is that it also includes a water spray assembly, the water spray assembly includes a water storage tank 22, an air pressurization assembly 23, and the top of the housing 3 is provided with Installation port 24, the water storage tank 22 is installed in the installation port 24, and the water storage tank 22 is located at the rear of the cleaning roller 2, and the side wall of the water storage tank 22 near the cleaning roller 2 side is provided with a mounting Platform 25, the cross-section of the installation platform 25 is a triangular structure, the installation platform 25 is provided with a number of high-pressure atomization nozzles 26, and the spraying direction of the high-pressure atomization nozzles 26 is towards the lowest end of the cleaning roller 2, and the air pressure The component 23 is installed on the water storage tank 22 to pressurize the inside of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com