Design method of soaking plate wick structure with enhanced capillary action

A technology of structural design and capillary action, applied in lighting and heating equipment, computer-aided design, design optimization/simulation, etc., can solve problems such as inability to meet the requirements of enhanced heat transfer, achieve superior thermal performance, and reduce labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The design method proposed by the present invention can be used in the design of various groove-type vapor chamber liquid-absorbing core structures to enhance capillary action. The following mainly takes the condensation end as an example, and describes the present invention in detail in conjunction with the accompanying drawings and examples.

[0064] A method for designing a structure of a vapor chamber liquid-absorbing core for strengthening capillary action, comprising the following steps:

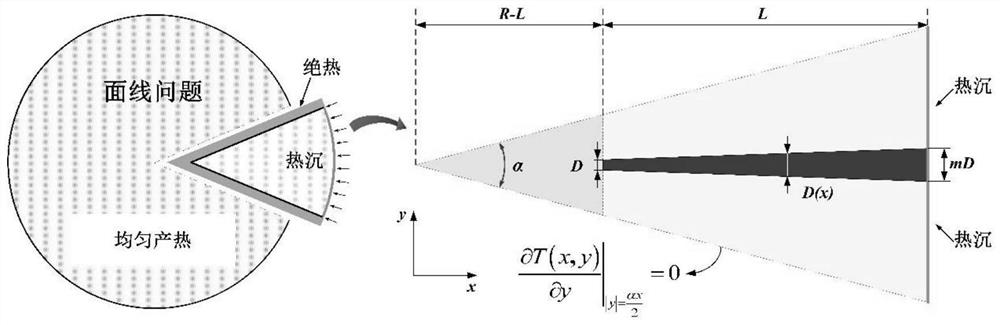

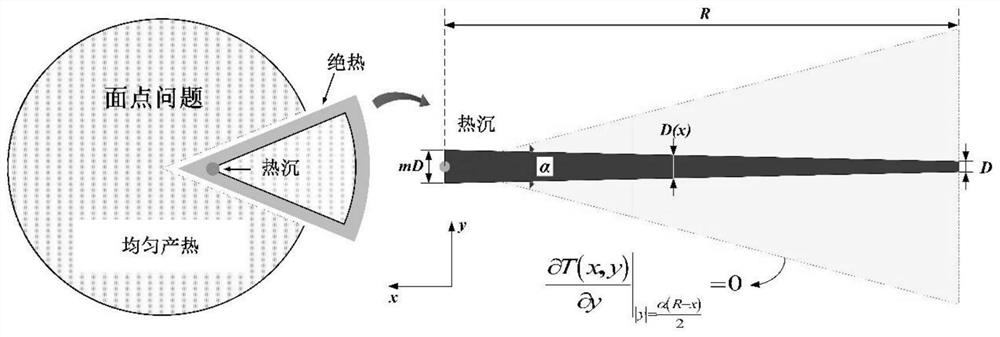

[0065] (1) Derivation of the first-order configuration of the liquid-absorbing core structure:

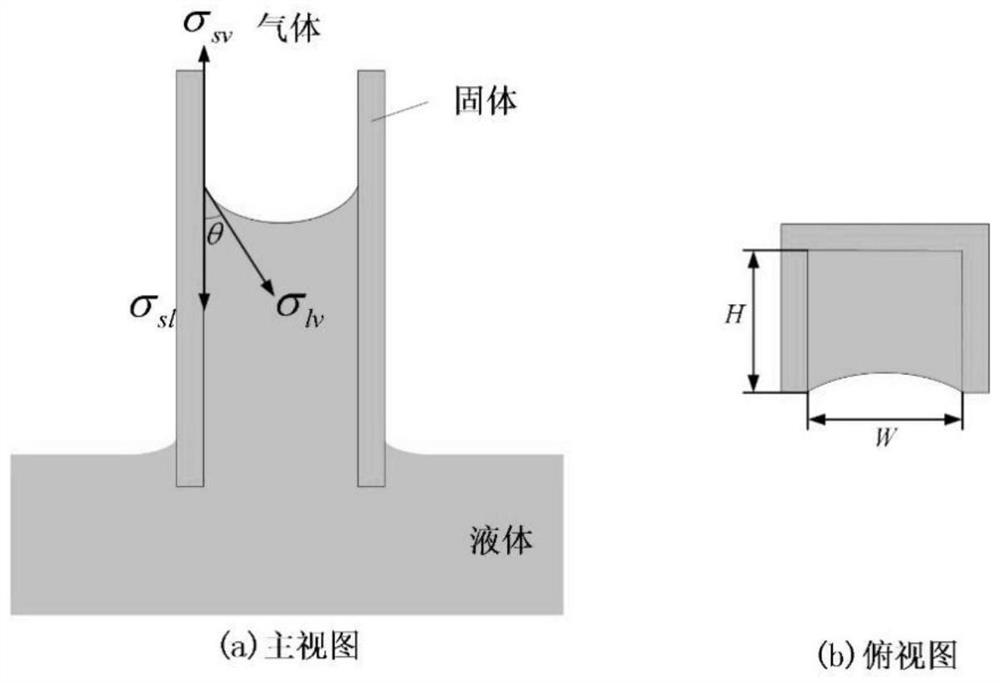

[0066] The height of the flow channel in the vapor chamber liquid-absorbing core structure is tens to hundreds of microns, which is regarded as a Poiseuille flow between parallel plates, and the relationship between the flow velocity and the pressure gradient of the Poiseuille flow is compared and analyzed, and the steady-state heat conduction state The relationship between heat flux...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com