Anti-rock-burst supporting frame for mining

A support frame and anti-shock technology, which is applied in the direction of mining equipment, pillars/brackets, roof beams supporting mine roofs, etc., can solve the problems of low support strength of wooden sheds, buffering of rock impacts, roadway blockages, etc., and achieve Ensure the support stability, prolong the service life and improve the effect of compressive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below.

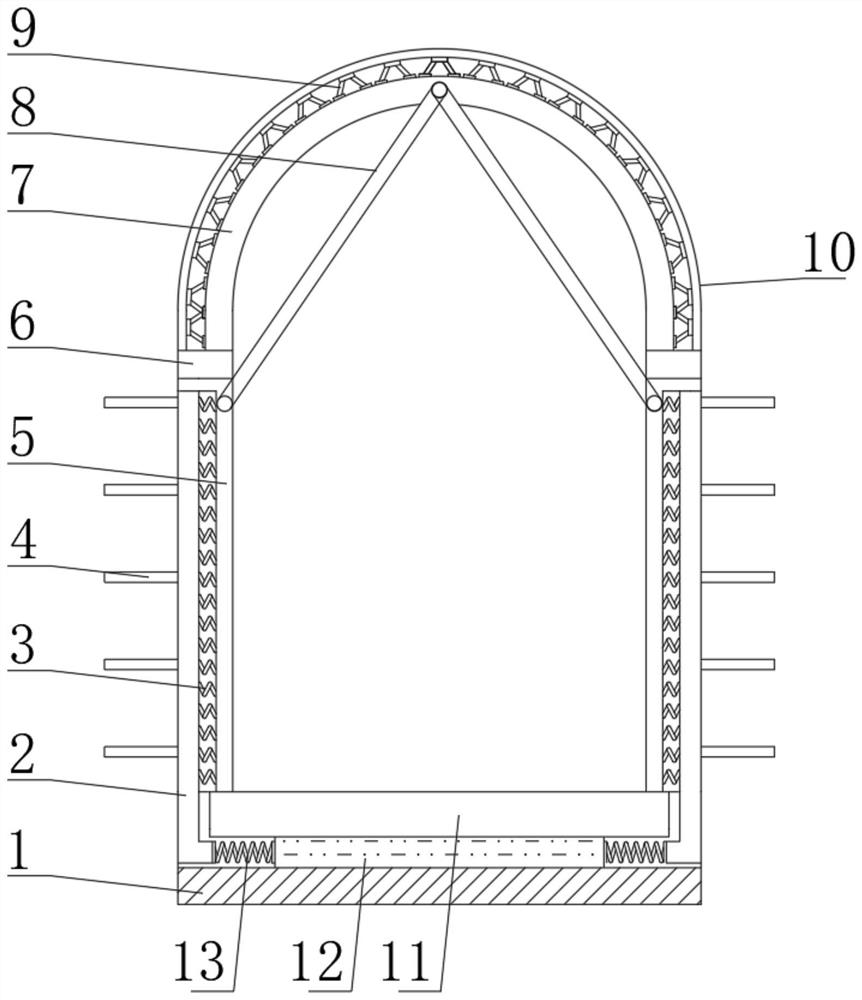

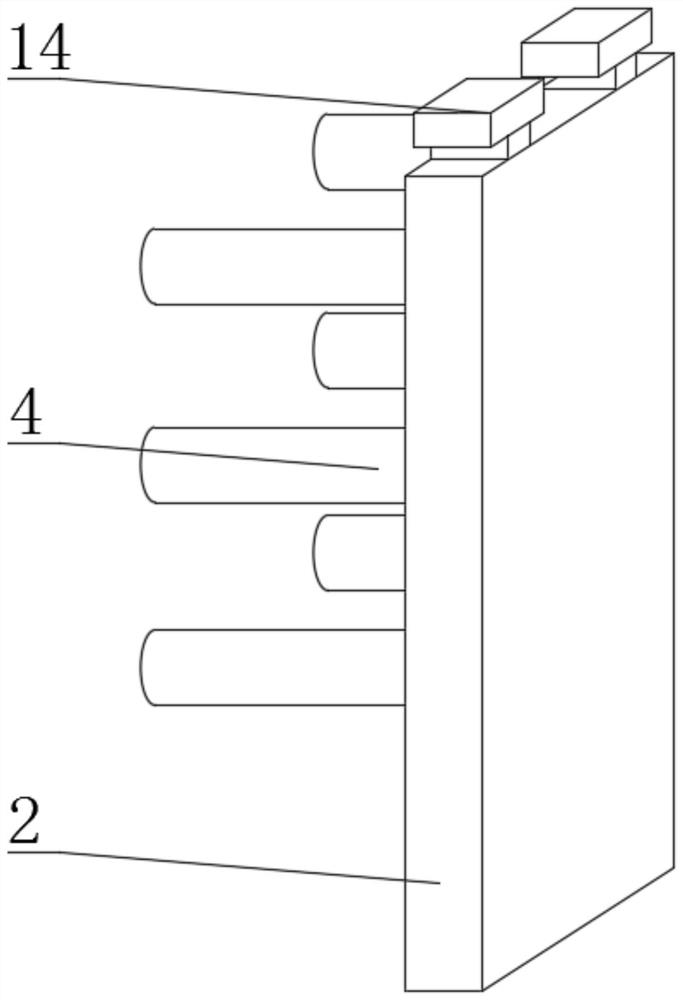

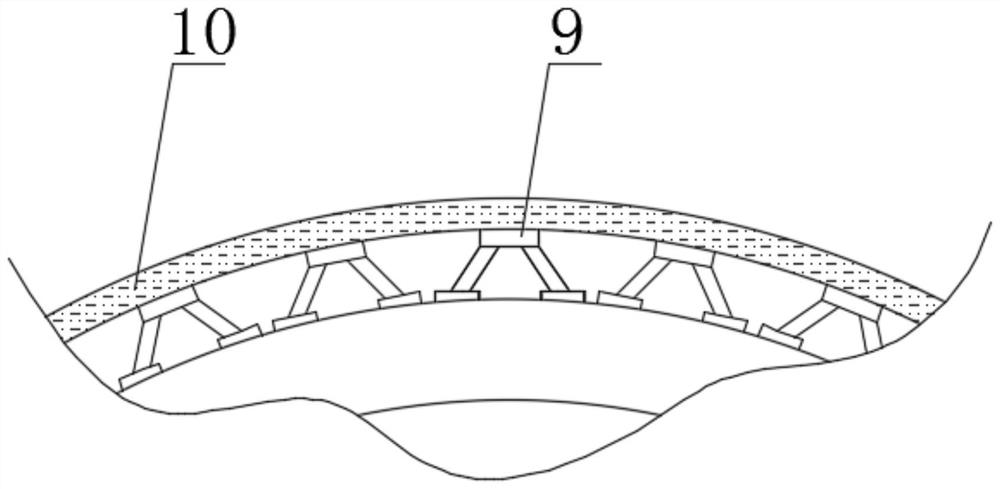

[0018] like Figure 1 to Figure 4 As shown, the present invention includes a fixed base plate 1, a bearing block 12, a pressure plate 11, two support plates 5, two buffer plates 2, two rubber plates 6, an arc support plate 7 and an arc anti-pressure plate 10,

[0019] The load-bearing block 12 is fixed on the fixed base plate 1, the pressing plate 11 is fixed on the load-bearing block 12, and the two buffer plates 2 are vertically placed on the fixed base plate 1 and symmetrically located on both sides of the pressing plate 11; the two support plates 5 are vertically It is fixed on the upper surface of the pressing plate 11 and is respectively close to both sides of the pressing plate 11; a plurality of first springs 3 are arranged between the support plate 5 and the buffer plate 2 on the same side of the pressing plate 11, and the two ends of the plurality of first springs 3 are respectively connected to the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com