Fruity cigarette paper and preparation method thereof

A cigarette paper and fruit technology, applied in the field of fruit-flavored cigarette paper and its preparation, can solve the problems of increasing the release of harmful components and uneven release of flavors and fragrances, and achieve the goals of reducing the generation of harmful components, uniform and stable release, and reducing differences Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

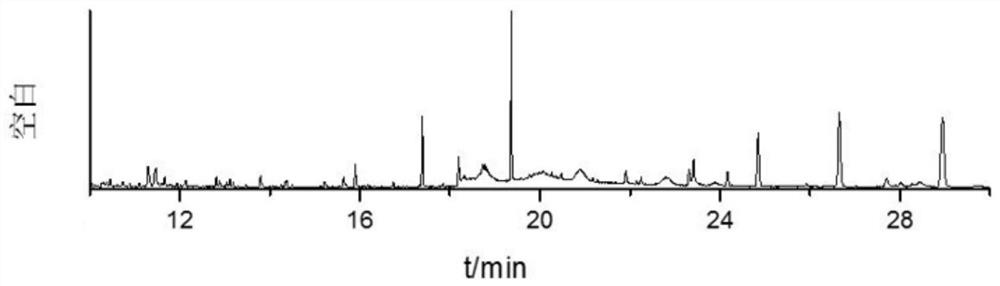

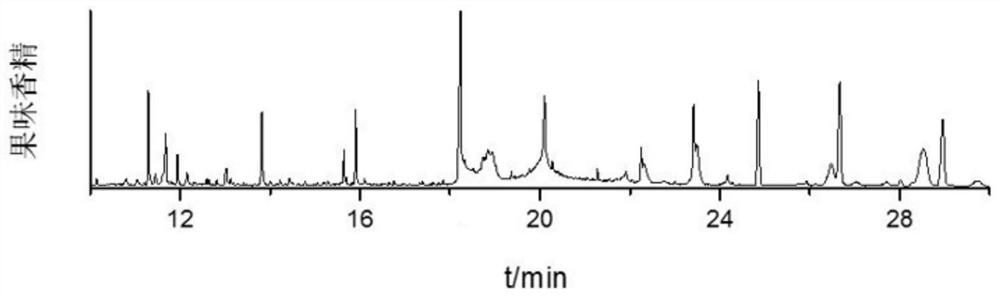

Image

Examples

Embodiment 1

[0026] Take by weighing the fruit flavor essence 0.15Kg that the apple extract that contains essential oil, 2% cloud smoke extract that contains essential oil, 2% rose oil, the pure water of remainder form and dissolve in the ethanol of 10.0Kg, make The concentration percentage of fruit flavor is 1.48%.

[0027] Cigarette paper is prepared according to the manufacturing process of cigarette paper: fiber raw materials are decomposed, beaten, the ratio of long and short fibers is adjusted, fillers and functional additives are added, and then dehydrated paper is formed, and then pressed, dried, and coiled. Weigh 50kg of freshly prepared cigarette paper, use an offline coating machine to spray the ethanol solution of fruit essence on the back of the cigarette paper offline, and then dry it in a low-temperature drying cylinder. cutting, that is to complete the preparation of fruit flavored cigarette paper A, and the amount of fruit flavor added accounts for about 3‰ of the weight o...

Embodiment 2

[0029] Take by weighing the fruit flavor essence 0.25Kg that the pure water that contains the mulberry fruit extract that contains essential oil of 20%, the Zimbabwe tobacco leaf extract that contains essential oil, the pure water of 6% is dissolved in the ethanol of 10.0Kg, makes The concentration percentage of fruit essence is 2.44%.

[0030] Cigarette paper is prepared according to the manufacturing process of cigarette paper: fiber raw materials are decomposed, beaten, the ratio of long and short fibers is adjusted, fillers and functional additives are added, and then dehydrated paper is formed, and then pressed, dried, and coiled. Weigh 50kg of freshly prepared cigarette paper, use an offline coating machine to spray the ethanol solution of fruit essence on the back of the cigarette paper offline, and then dry it in a low-temperature drying cylinder. Cutting, that is to complete the preparation of fruit flavored cigarette paper B, the amount of fruit flavor added accounts...

Embodiment 3

[0032] Weigh 0.50Kg of fruity flavor essence consisting of 10% essential oil-containing blueberry extract, 8% essential oil-containing Zimbabwe tobacco leaf extract, 5% sweet fennel oil, and pure water of the remainder and dissolve in 10.0Kg of ethanol , so that the concentration percentage of fruit essence is 4.77%.

[0033] Cigarette paper is prepared according to the manufacturing process of cigarette paper: fiber raw materials are decomposed, beaten, the ratio of long and short fibers is adjusted, fillers and functional additives are added, and then dehydrated paper is formed, and then pressed, dried, and coiled. Weigh 50kg of freshly prepared cigarette paper, use an offline coating machine to spray the ethanol solution of fruit essence on the back of the cigarette paper offline, and then dry it in a low-temperature drying cylinder. Cutting means to complete the preparation of the fruit flavored cigarette paper C, and the added amount of the fruit flavor accounts for about...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com