Cosmetic plant essence extraction method

A plant essence and cosmetic technology, applied in the directions of essential oils/spices, fat production, etc., can solve the problems of uneven distillation speed of heated essential oils, slow heating of materials, and reduced purity of essential oils, etc., to improve the spray range, improve uniformity, The effect of large spray distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in a variety of different ways defined and covered by the claims.

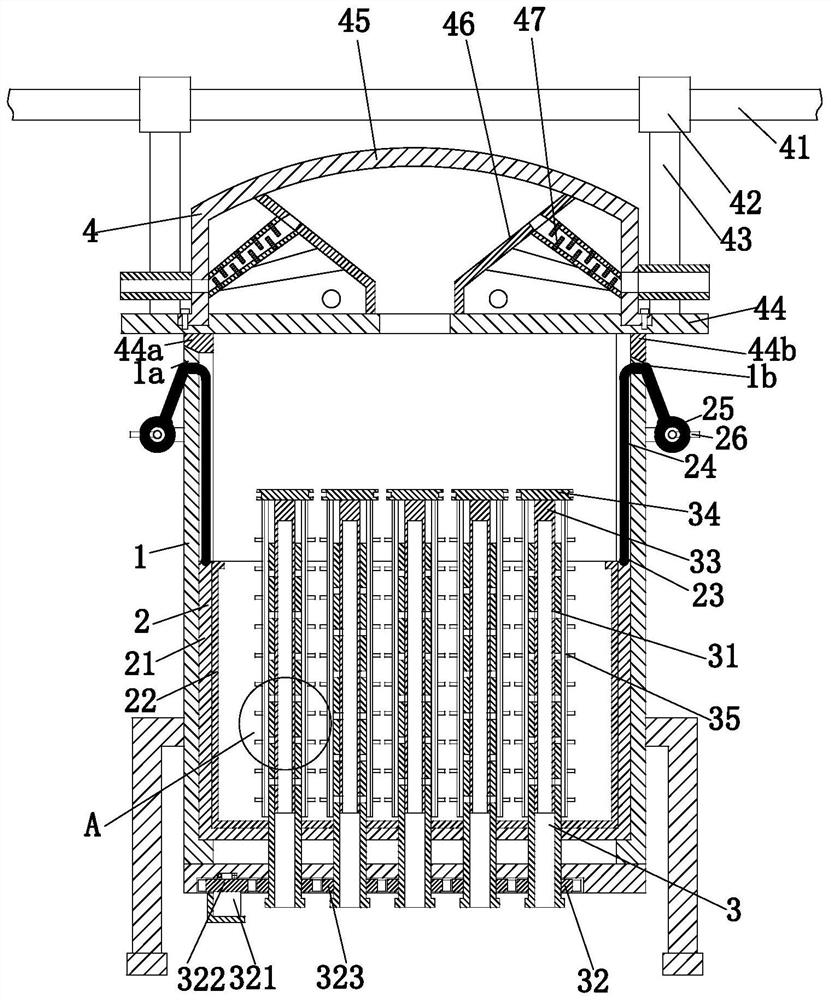

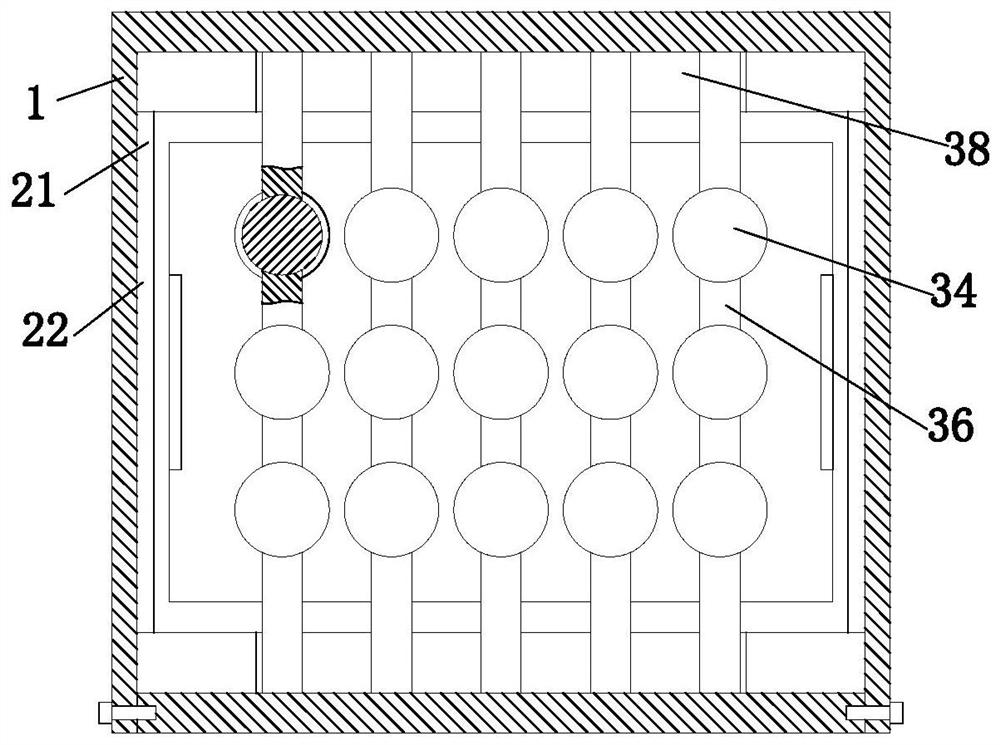

[0036] Such as Figure 1 to Figure 6 As shown, a method for extracting cosmetic plant essences uses a distillation extraction equipment. The distillation extraction equipment includes a housing 1, a material frame 2, a ventilation device 3, and a condensation device 4. When the above extraction equipment is used to prepare plant essences The specific method flow is as follows:

[0037] S1. Raw material crushing: the plant raw materials are washed and then crushed to speed up the extraction of essential oils;

[0038] S2. Steam inlet: Put the raw materials processed by S1 into the holding frame 2, and pass steam from below the aerator 3;

[0039] S3. Distillation extraction: the steam introduced into the aeration device 3 distills the raw materials ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com