Preparation method of graphene oxide reinforced polymethyl methacrylate/carbon microsphere composite material

A technology of polymethyl methacrylate and composite materials, which is applied in the field of nanomaterials, can solve problems such as softening and affecting performance, and achieve the effects of improving service life performance, low equipment requirements, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

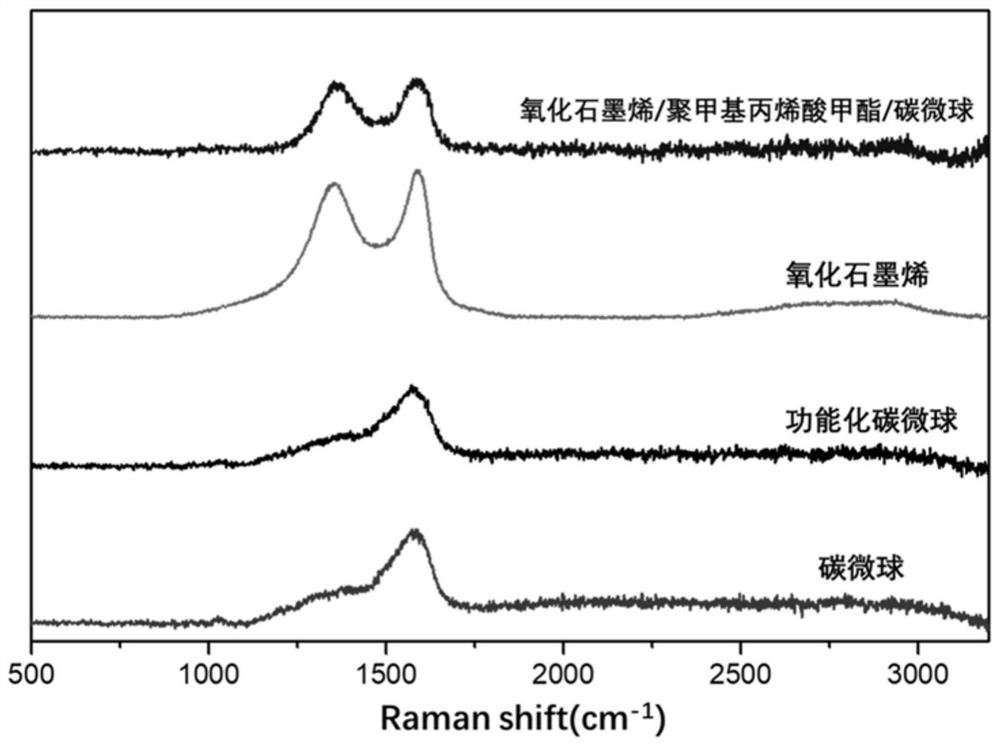

Image

Examples

preparation example Construction

[0029] A preparation method of graphene oxide reinforced polymethyl methacrylate / carbon microsphere composite material, comprising the following steps:

[0030] 1) Using glucose solution as carbon source, through hydrothermal reaction, the temperature of hydrothermal reaction is 180°C, and the time is 12h. After the completion, the product is washed several times, suction filtered, and dried to obtain carbon microspheres. The concentration of glucose solution is 40mg / mL;

[0031] 2) Dissolve the dry carbon microspheres in the mixed solution of water and absolute ethanol (the volume ratio of deionized water and absolute ethanol is 5:4), and every 90mL of the mixed solution of deionized water and absolute ethanol Add 0.2g carbon microspheres, then add the mixed solution of silane coupling agent and absolute ethanol (the silane coupling agent adopts KH550, the mixed solution of silane coupling agent and absolute ethanol is specifically: add 5ml Silane coupling agent), condensed ...

Embodiment 1

[0037] 1) Prepare a glucose solution with a concentration of 40 mg / mL, conduct hot water thermal reaction at 180°C for 12 hours, wash the product several times, filter it with suction, and dry it in an oven at 80°C for 12 hours to obtain carbon microspheres;

[0038]2) Dissolve 0.2g of dry carbon microspheres in a mixed solution of 50ml of deionized water and 40ml of absolute ethanol, add 5ml of silane coupling agent and 20ml of absolute ethanol to prepare the mixed solution, and react at 60°C under reflux conditions After 12 hours, the product was washed several times, filtered with suction, and dried in an oven at 80°C for 12 hours to obtain modified carbon microspheres;

[0039] 3) The modified carbon microspheres after drying, water and methyl methacrylate are made into solution A, wherein the concentration of modified carbon microspheres in solution A is 5 mg / mL, and the addition of methyl methacrylate is modified 0.2wt% of the mass of carbon microspheres, feed nitrogen a...

Embodiment 2

[0043] 1) Prepare a glucose solution with a concentration of 40 mg / mL, conduct hot water thermal reaction at 180°C for 12 hours, wash the product several times, filter it with suction, and dry it in an oven at 80°C for 12 hours to obtain carbon microspheres;

[0044] 2) Dissolve 0.2g of dry carbon microspheres in a mixed solution of 50ml of deionized water and 40ml of absolute ethanol, add 5ml of silane coupling agent and 20ml of absolute ethanol to prepare the mixed solution, and react at 60°C under reflux conditions After 12 hours, the product was washed several times, filtered with suction, and dried in an oven at 80°C for 12 hours to obtain modified carbon microspheres;

[0045] 3) The modified carbon microspheres after drying, water and methyl methacrylate are made into solution A, wherein the concentration of modified carbon microspheres in solution A is 6 mg / mL, and the addition of methyl methacrylate is modified 0.2wt% of the mass of carbon microspheres, feed nitrogen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com