Preparation method of high-purity methyl oleate

A technology of methyl oleate and methyl linoleate, which is applied in the field of preparation of high-purity methyl oleate, can solve problems such as cumbersome operation, and achieve the effect of good color and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

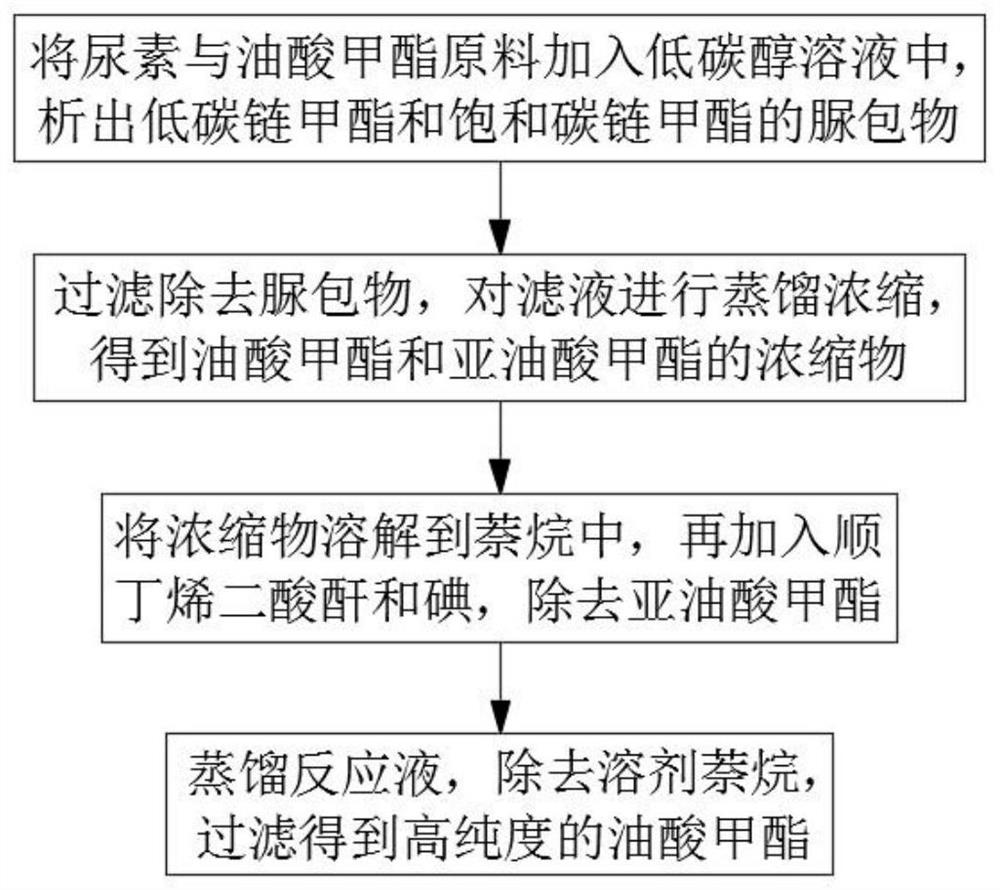

[0026] see figure 1 , the invention provides a kind of preparation method of high-purity methyl oleate, comprises the following steps,

[0027] S1, adding urea and methyl oleate raw materials into a low-carbon alcohol solution, heating and dissolving to a homogeneous solution, cooling and freezing the homogeneous solution, and separating urea-coated substances of low-carbon chain methyl esters and saturated carbon-chain methyl esters.

[0028] Excessive water content, insufficient urea dosage and high freezing temperature will result in insufficient separation of saturated fatty acid methyl esters. In order to effectively improve the separation efficiency of saturated fatty acid methyl ester, the present invention has carried out the reasonable control of the consumption of each reagent and temperature, preferably, the mass ratio of described urea and methyl oleate raw material is m 尿素 :m 油酸甲酯 =3~8:1, where m 尿素 is the mass of urea, m 油酸甲酯 is the mass of methyl oleate. Th...

Embodiment 1

[0034] Example 1: 2.4kg water content is 25% isopropanol solution is added in the reactor of 10L, then add 0.4kg typical methyl oleate and 1.2kg urea successively, heat to 80 ℃ and make urea dissolve, cool to Crystallized at -10°C, filtered to remove crystals, and then distilled to remove the solvent to obtain intermediate product A.

Embodiment 2

[0035] Example 2: Add 4.0kg of ethanol solution with a water content of 15% into a 10L reactor, then add 0.2kg of typical methyl oleate and 1.0kg of urea in turn, heat to 70°C to dissolve the urea, and cool to -20 °C to crystallize, remove the crystals by filtration, and then distill off the solvent to obtain the intermediate product B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com