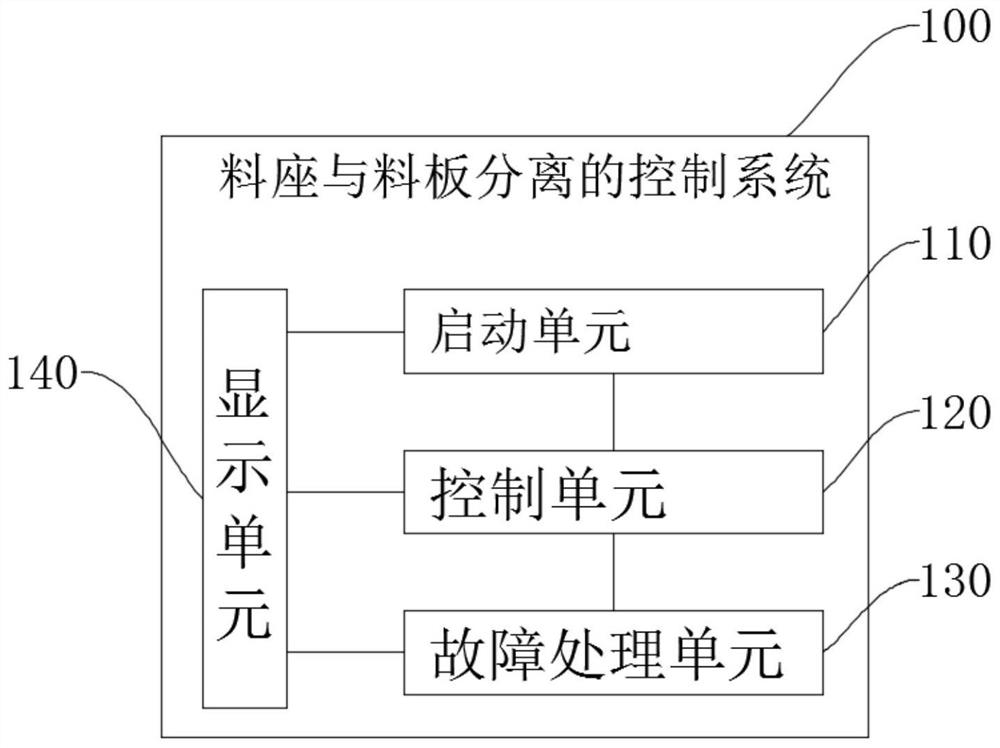

Control system for separating material seat from material plate, material seat and monocrystalline silicon piece

A control system and control unit technology, applied in the direction of manufacturing tools, fine working devices, stone processing equipment, etc., can solve problems such as low work efficiency, waste of energy such as water, electricity, and inability to ensure product consistency, etc., to achieve improved productivity efficiency, safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

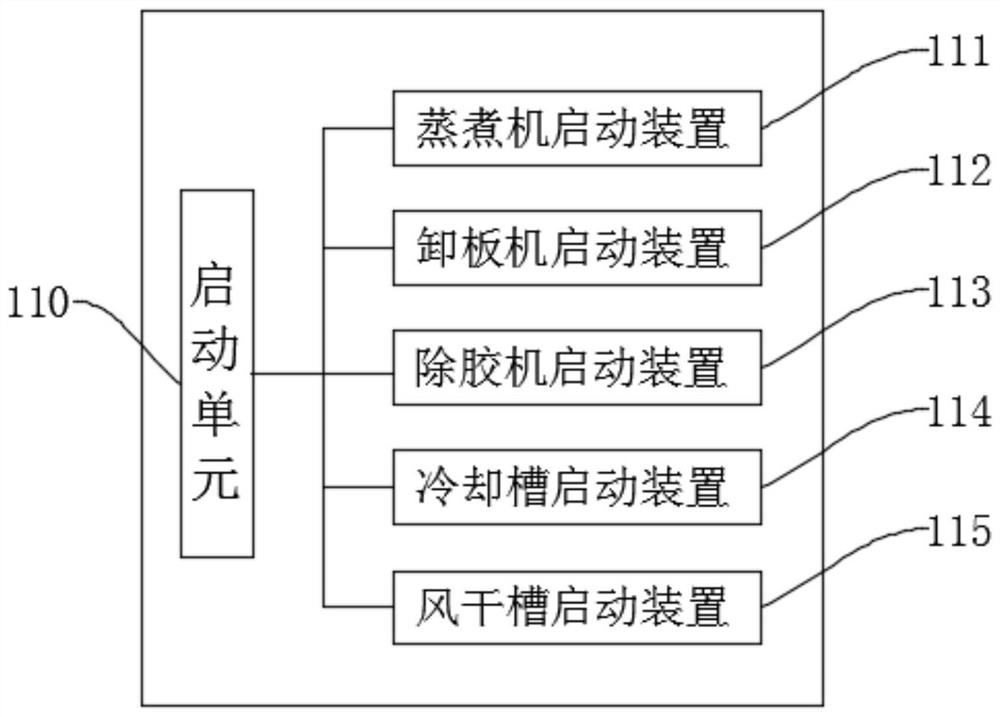

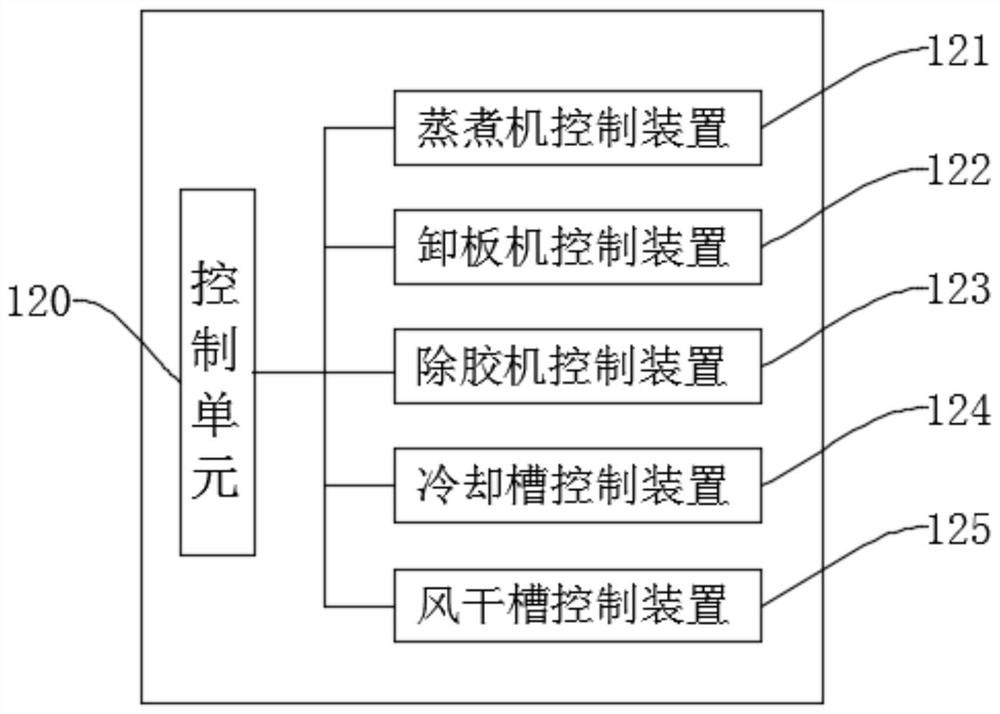

[0058]In this embodiment, the material board and the material seat are operated and controlled sequentially through the process of the cooking machine, plate unloading machine, glue remover, cooling tank and air-drying tank, mainly: in the cooking machine, make the gap between the material board and the material seat The rubber layer is softened, so that it is easy to shovel the plate in the unloader; firstly, the material plate and the material seat are separated in the shovel mechanism of the plate unloader, and then the material plate is unloaded from the material seat in the push plate mechanism to separate the material board from the material seat; in the glue remover, use a scraper device and a spray device to remove the residual glue on the material seat and rinse the residual glue to ensure that the material seat is clean; clean the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com