Metal workpiece machining device utilizing thread cutting

A metal workpiece and processing device technology, applied in the field of metal workpiece processing devices, can solve the problems of adjusting the water output of the workpiece, poor cutting lines, and affecting thread formation, etc., to achieve good clamping effect, good lines, and avoid shaking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing:

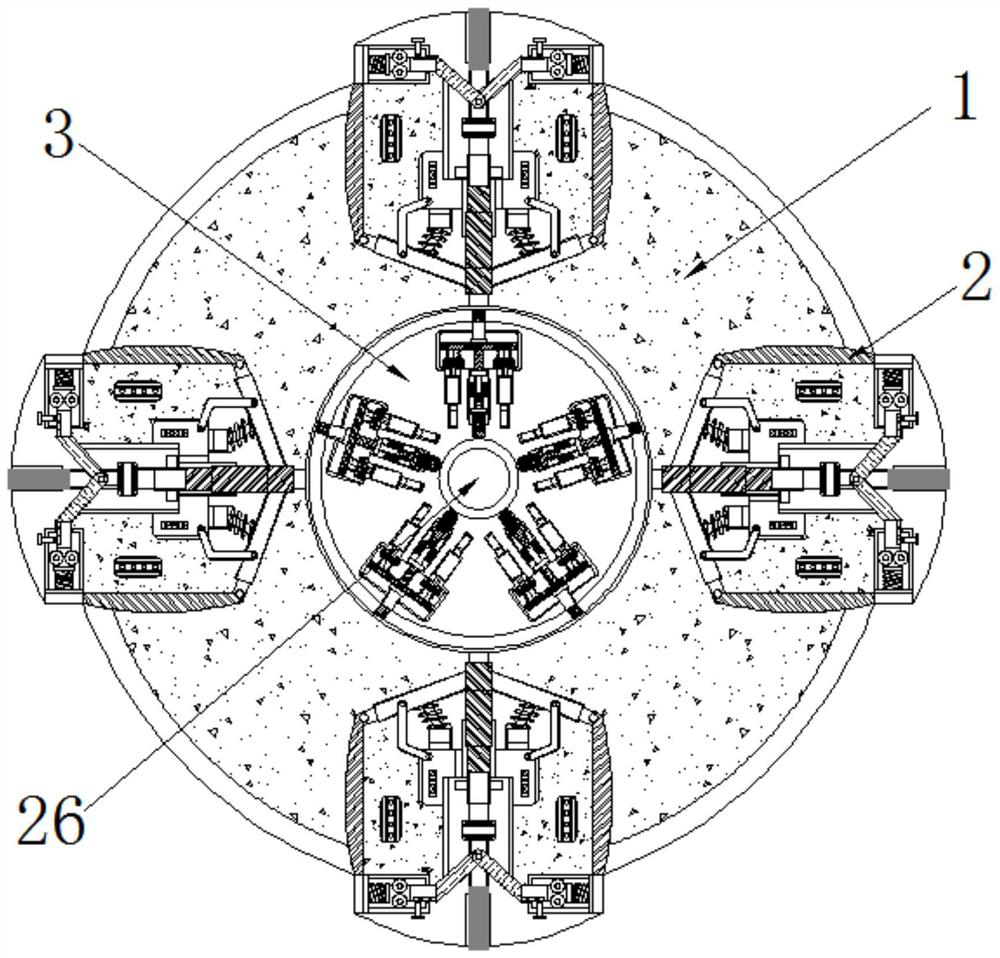

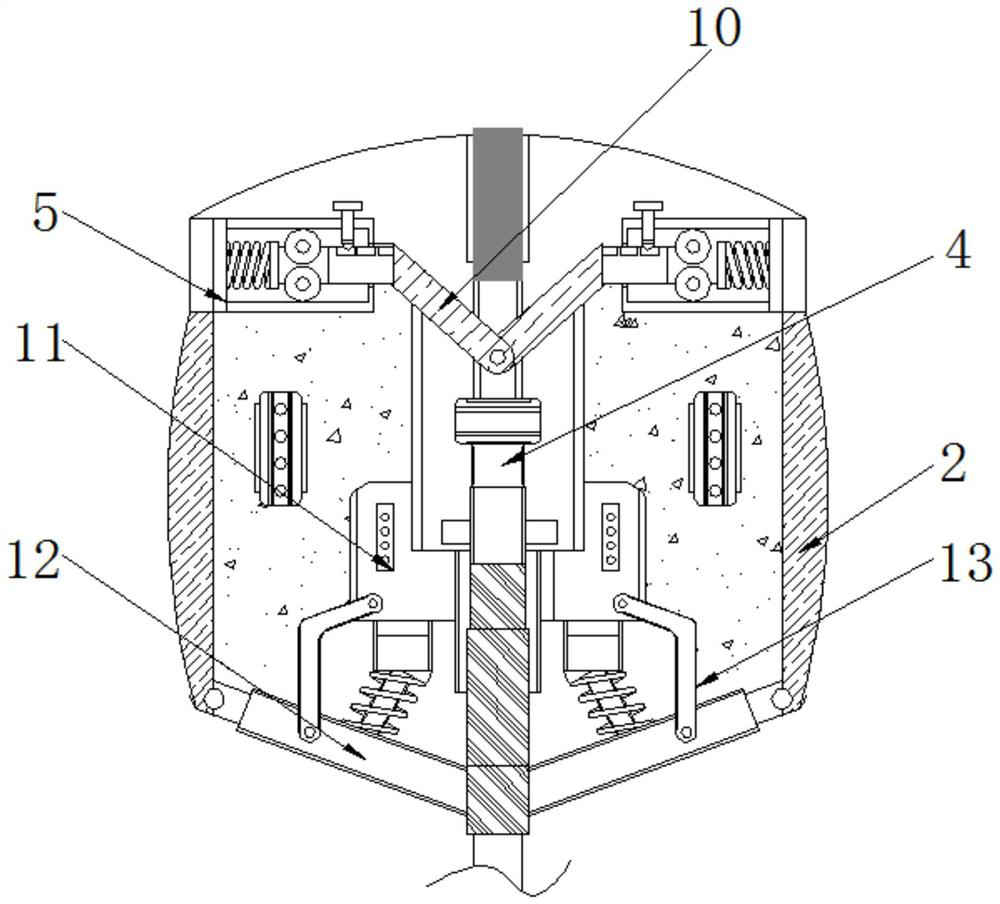

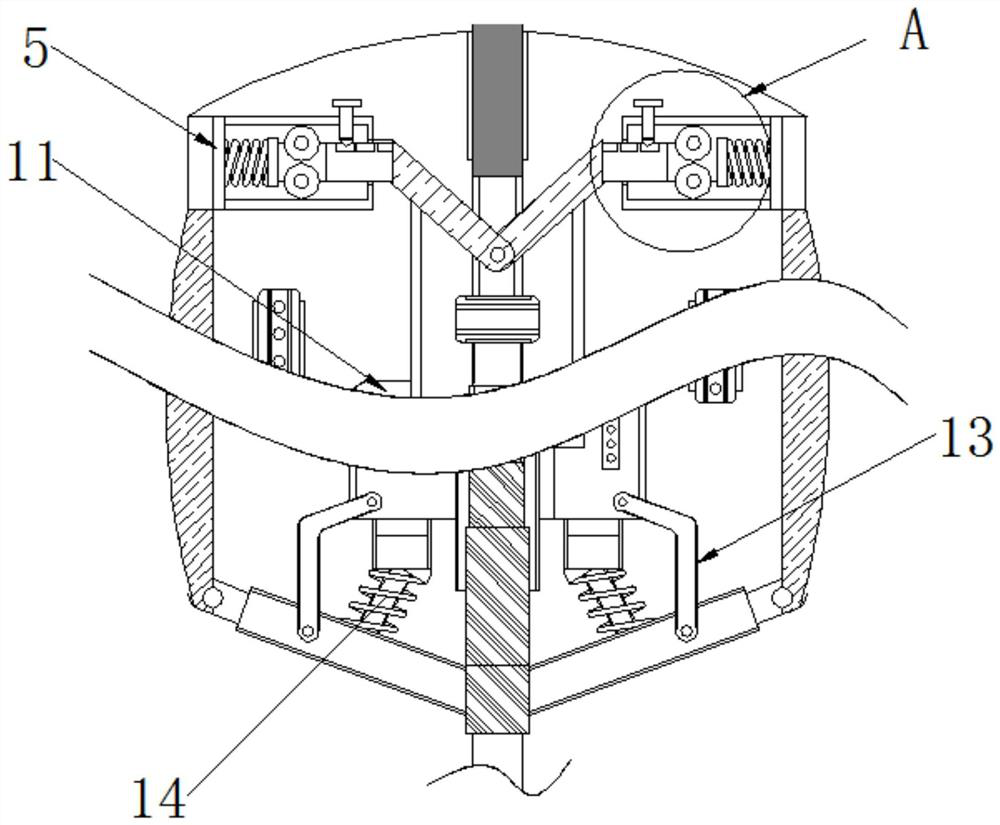

[0025] as attached figure 1 to attach Figure 8 Shown:

[0026] The invention provides a metal workpiece processing device utilizing thread cutting, comprising a chuck 1, an installation frame 2 is arranged inside the chuck 1, an adjusting plate 3 is arranged inside the chuck 1, and the inner wall of the installation frame 2 is movably connected with Sliding column 4, the inner wall of mounting bracket 2 is fixedly connected with limit seat 5, the interior of limit seat 5 is connected with limit spring 6, and one side of limit spring 6 is movably connected with limit column 7, and the surface of limit column 7 is opened There is a card slot 8, the inside of the card slot 8 is movably connected with a card post 9, the shape of the card slot 8 is compatible with the shape of the card post 9, the diameters of the adjacent card slots 8 are equidistantly arranged, and the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com