Square sedimentation tank and mud scraper

A square and mud scraper technology, which is applied in the direction of sedimentation separation, settling tank, separation method, etc., can solve the problems of low land utilization rate and difficult construction of radial flow sedimentation tank, and achieve good mud scraping effect and slag scraping effect , the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

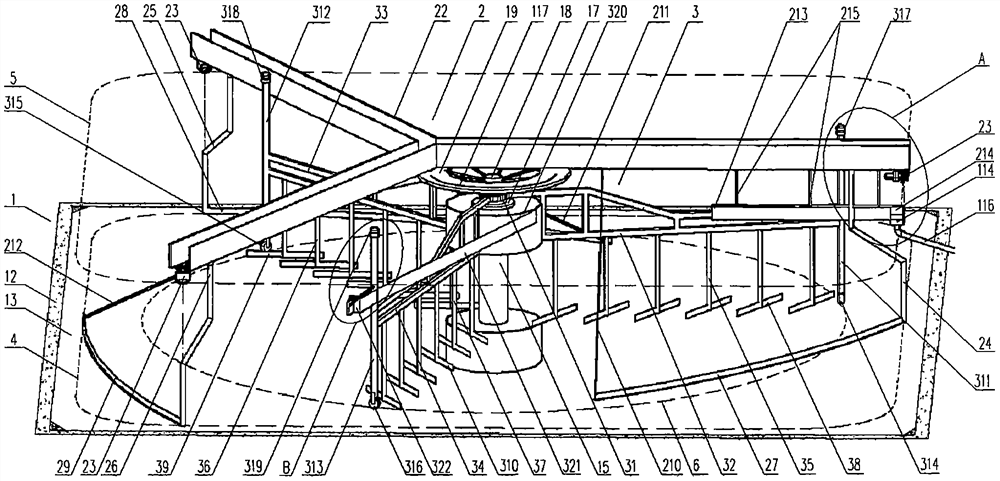

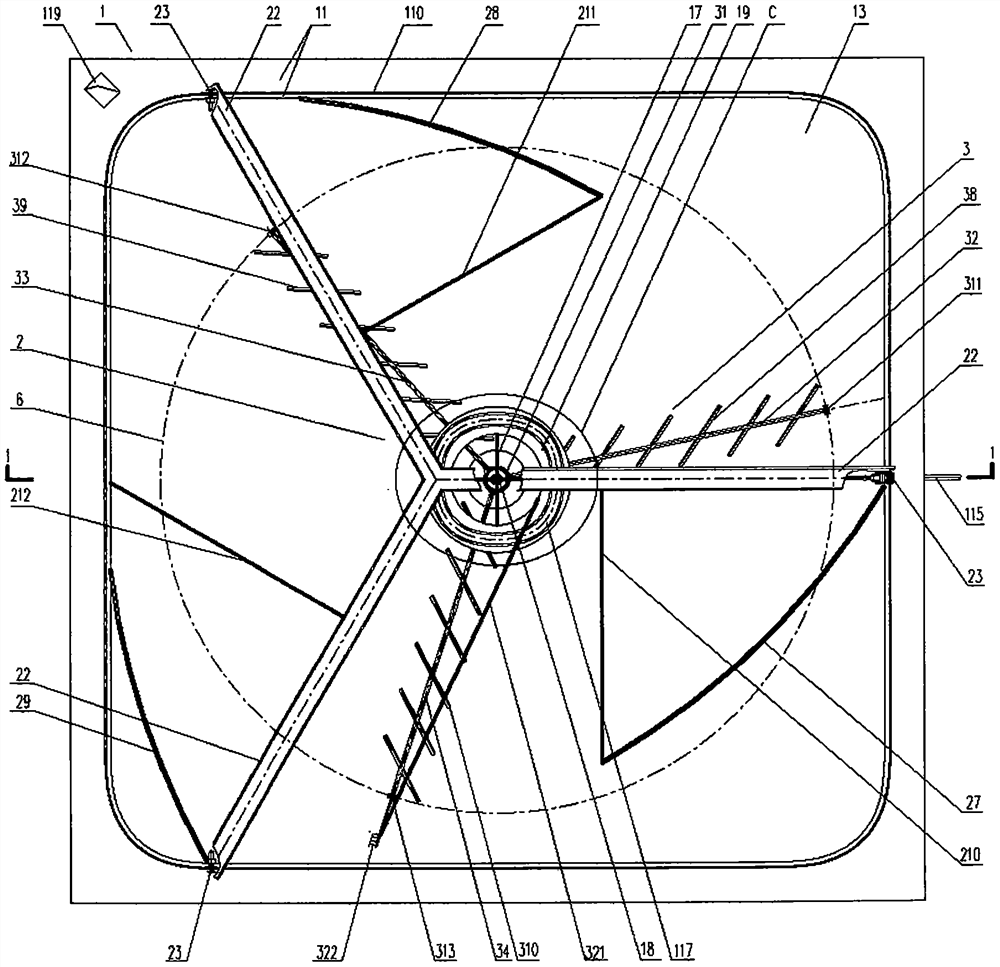

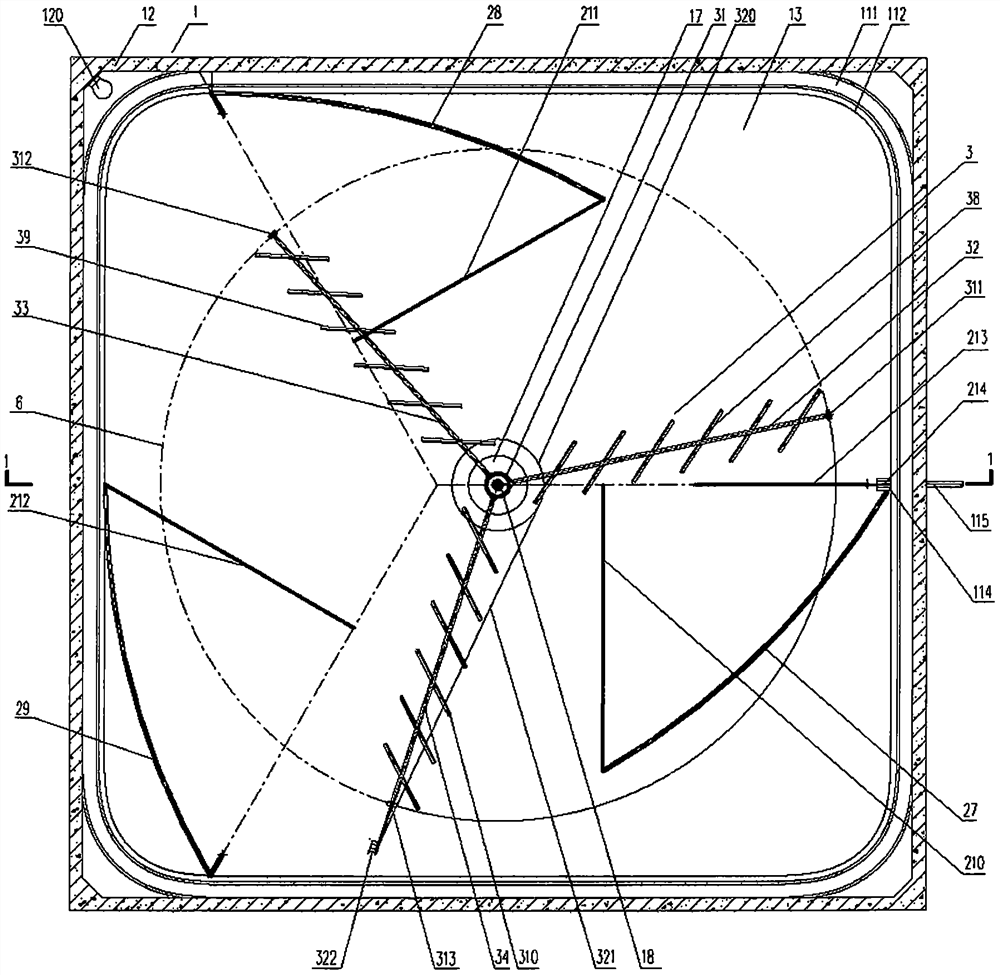

[0048] see Figure 1-8 , the inner diameter of the square pool body 1 is designed to be 31.6m, that is, the side length of the square obtained by the intersection of the bottom 13 of the pool and the vertical pool wall 12 in the pool is 31.6m, and the square is offset by 0.8m to the inside of the pool to obtain a square with a side length of 30m and Draw the Lello triangle whose fixed width is 30m. This Lello triangle rotates in the square with a side length of 30m to form a quasi-square trajectory line 4 with approximately rounded corners. This is the 1# connecting rod 24, the 2# connecting rod 25 and 3 #The movement track line of the lowermost end of the connecting rod 26. The horizontal projection of the rail center line 5 and the horizontal projection of the scum baffle 112 fall on the quasi-square trajectory line 4 . One end of the corner skimmer rotating shaft 216 is close to the scum baffle 112. The length of the 1# corner scraper 27 (2# corner scraper 28, 3# corner sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com