Feed for improving piglet production performance by using dry-fried raw materials and preparation method thereof

A production performance and feed technology, applied in the field of feed, can solve the problems of failing to improve the intestinal health of piglets, fat oxidation and rancidity, affecting the use effect, etc., and achieve the effects of improving piglet production performance, avoiding fat oxidation, and increasing utilization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

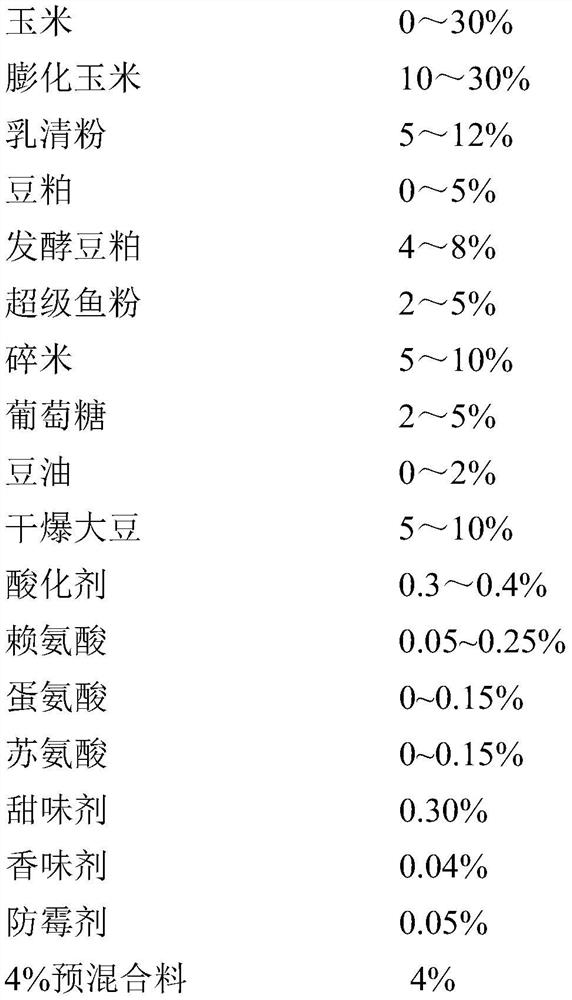

[0048] One, the present invention a kind of feed that uses dry-explosive raw material to improve the production performance of piglets,

[0049] Formula is as follows: (mass percentage meter)

[0050]

[0051]

[0052] The above-mentioned raw materials, except dry-exploded soybeans, can be purchased in the raw material market.

[0053] The dry-exploded soybeans are produced through the following process: ①Through the soybeans through a three-cleaning sieve to remove impurities; ②Transport the three-cleared soybeans to the temporary storage warehouse; The soybean machine roasts soybeans through the hot air generated by gas combustion; ⑤The temperature of the dry-exploded soybean machine is controlled at 195°C, and the time for soybeans to pass through the dry-exploded soybean machine is 120 seconds; ⑥After the soybeans are dry-exploded, they enter the crusher for crushing;⑦ The crushed dry-exploded soybeans enter the cooler; ⑧the material is cooled in the cooler for 360 ...

Embodiment 2

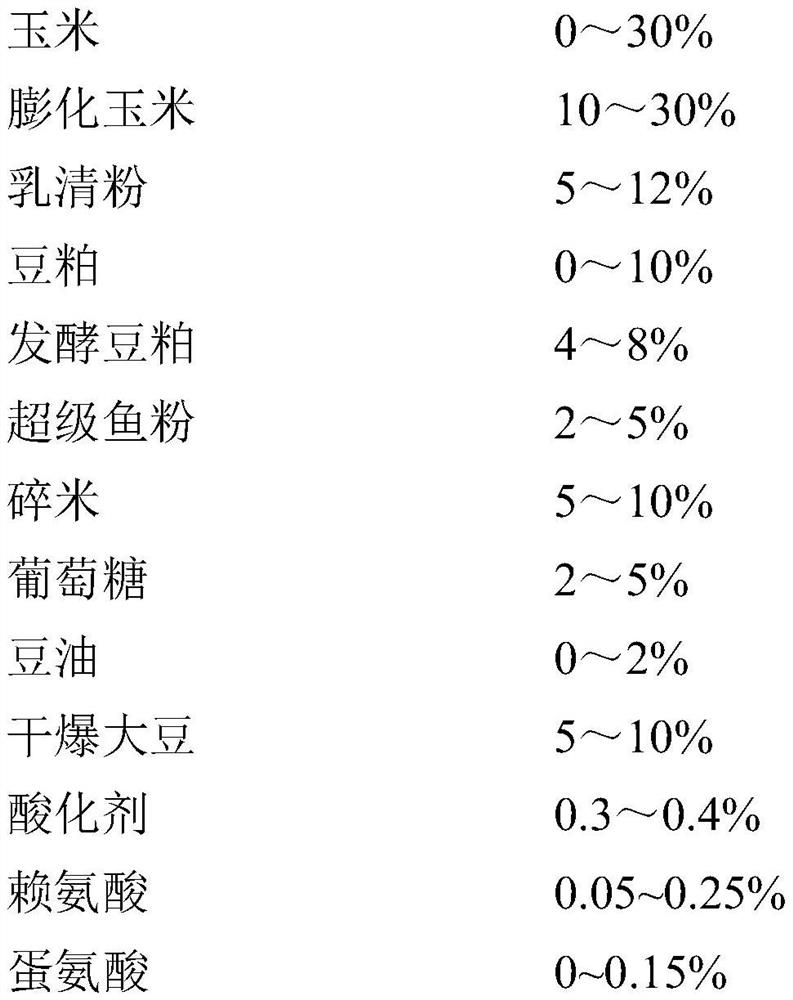

[0064] One, the present invention a kind of feed that uses dry-explosive raw material to improve the production performance of piglets,

[0065] Formula is as follows: (mass percentage meter)

[0066]

[0067]

[0068] The above-mentioned raw materials, except dry-exploded soybeans, can be purchased in the raw material market.

[0069] The dry-exploded soybeans are produced through the following process: ①Through the soybeans through a three-cleaning sieve to remove impurities; ②Transport the three-cleared soybeans to the temporary storage warehouse; The soybean machine roasts the soybeans through the hot air generated by gas combustion; ⑤The temperature of the dry-exploded soybean machine is controlled at 185°C, and the time for the soybeans to pass through the dry-exploded soybean machine is 120 seconds; ⑥After the soybeans are dry-exploded, they enter the crusher for crushing;⑦ The crushed dry-exploded soybeans enter the cooler; ⑧the material is cooled in the cooler ...

Embodiment 3

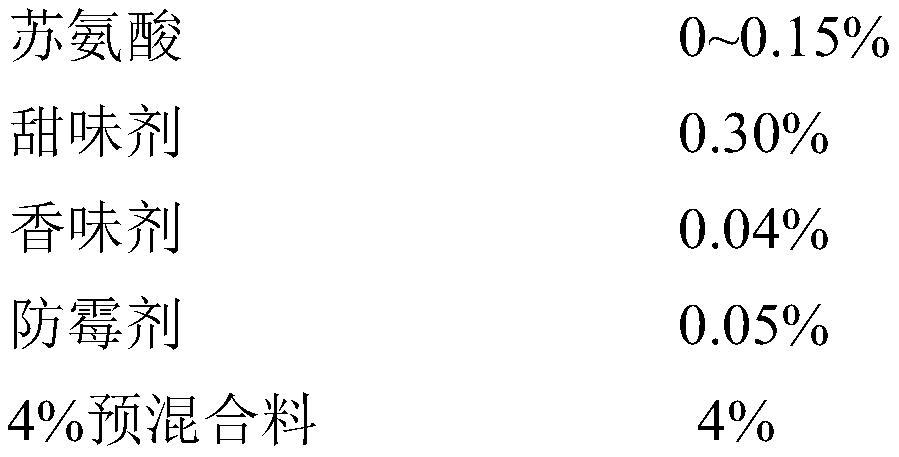

[0080] One, the present invention a kind of feed that uses dry-explosive raw material to improve the production performance of piglets,

[0081] Formula is as follows: (mass percentage meter)

[0082]

[0083]

[0084] The above-mentioned raw materials, except dry-exploded soybeans, can be purchased in the raw material market.

[0085] The dry-exploded soybeans are produced through the following process: ①Through the soybeans through a three-cleaning sieve to remove impurities; ②Transport the three-cleared soybeans to the temporary storage warehouse; The soybean machine roasts soybeans through the hot air generated by gas combustion; ⑤The temperature of the dry-exploded soybean machine is controlled at 190°C, and the time for soybeans to pass through the dry-exploded soybean machine is 150 seconds; ⑥After the soybeans are dry-exploded, they enter the crusher for crushing;⑦ The crushed dry-exploded soybeans enter the cooler; ⑧the material is cooled in the cooler for 330 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com