Display panel, preparation method thereof and display device

A technology for a display panel and a bending area, applied in the fields of its preparation, display device, and display panel, can solve the problems of difficult manufacturing process, complicated process, influence on display effect, etc., so as to avoid bending fracture, relieve stress, and reduce risk. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those skilled in the art without creative work shall fall within the protection scope of the present invention.

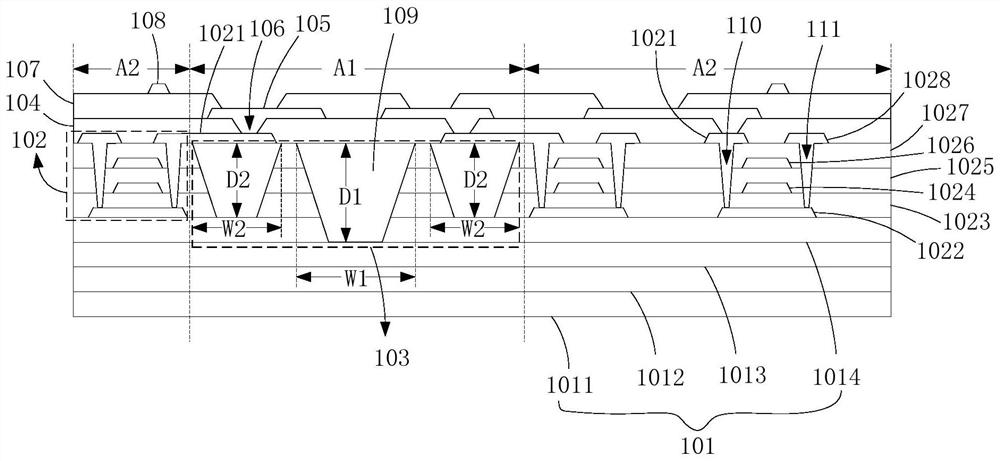

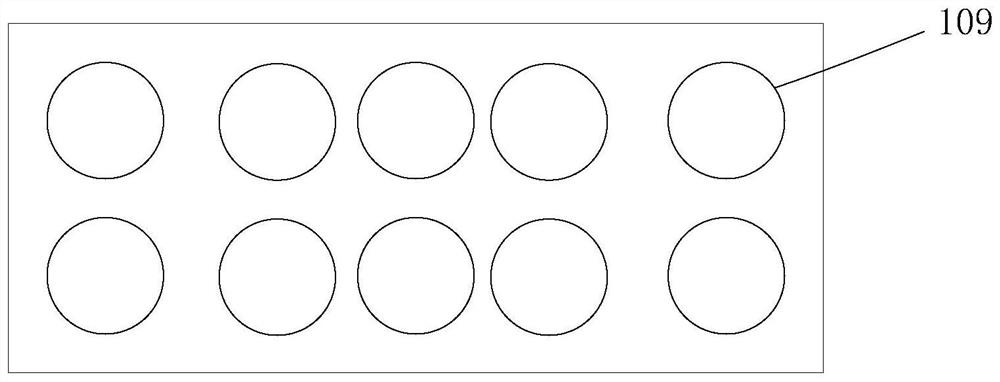

[0021] Such as figure 1 As shown, the schematic diagram of the basic structure of the display panel provided by the embodiment of the present invention, from which the various components of the present invention and the relative positional relationship between the components can be seen very intuitively. The display panel is divided into curved In the folding area A1 and the non-bending area A2, the display panel includes: a substrate layer 101; a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com