Combustion chamber special for marine diesel engine, combustion system and combustion method

A marine diesel engine and combustion chamber technology, applied in the field of combustion chambers, can solve problems such as incomplete oil-gas mixing and unreasonable structure, and achieve the effects of reducing oil-gas over-concentration areas, promoting oil-gas mixing, and improving the mixing degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

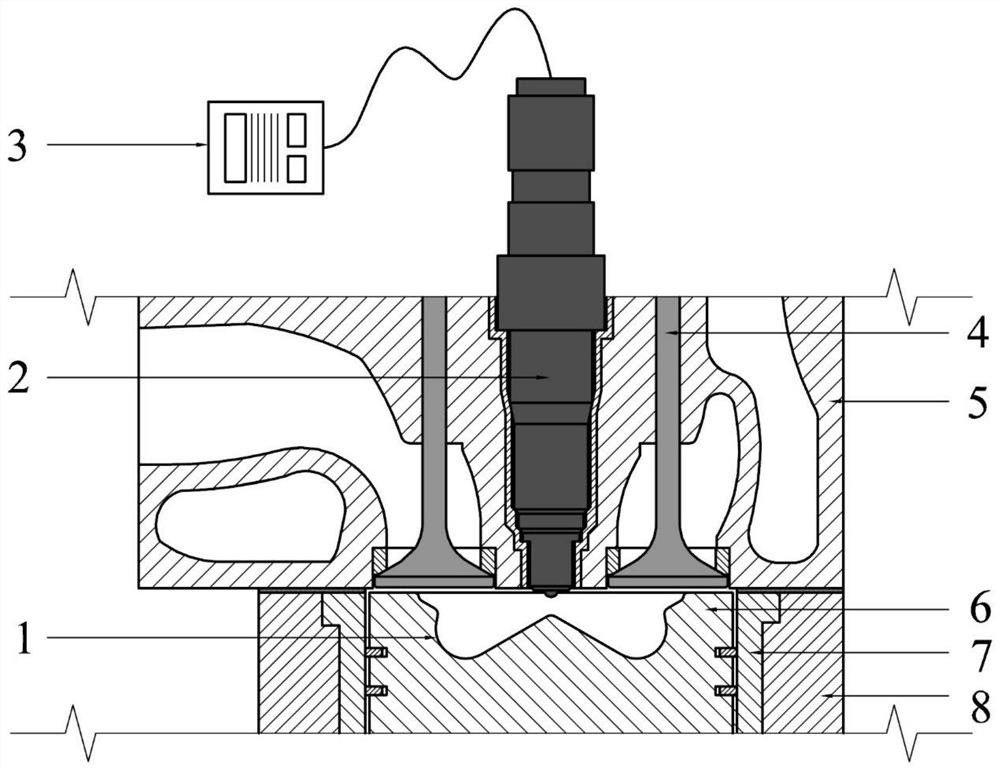

[0025] The shape and structural parameters of the combustion chamber of a diesel engine are crucial to the airflow movement in the cylinder, the formation of the fuel-air mixture and the combustion process, and ultimately affect the performance and emissions of the diesel engine.

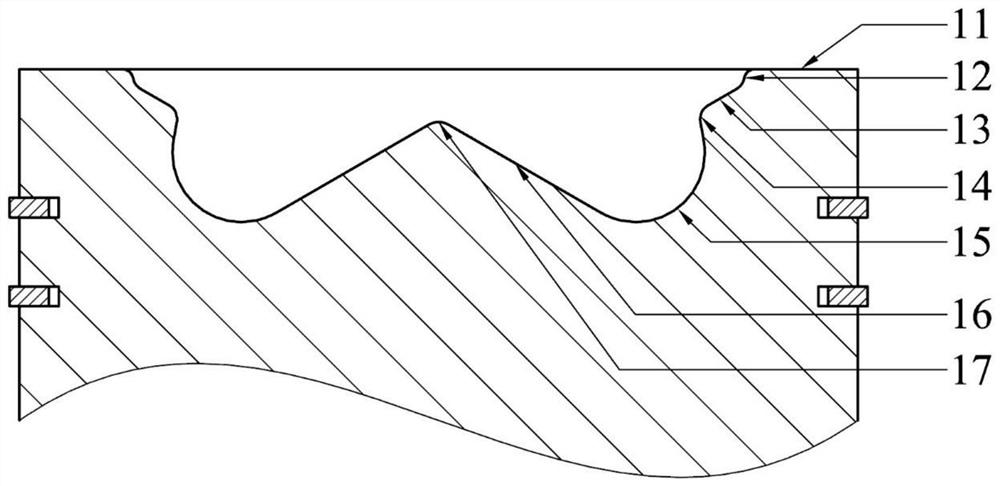

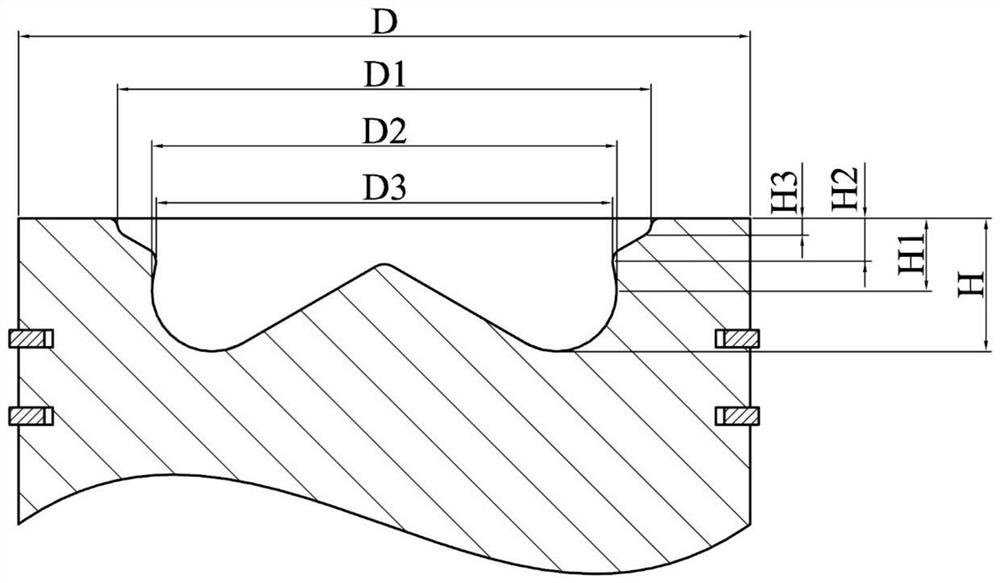

[0026] like figure 1 The structure of the combustion chamber 1 of the present invention is that the bottom of the combustion chamber 1 is provided with a boss 17 and a pit 15, and the boss 17 and the pit 15 are all arc wall surfaces, and the diversion slope 16 is connected with the boss 17 and the pit 15. The dimples 15 are tangential. The upper part of the combustion chamber 1 is provided with a constriction 14 , the lower part of the constriction 14 is connected with the pit 15 , and the upper part is connected with the stepped slope 13 . A vertical guide surface 12 is provided between the step slope 13 and the piston top surface 11 , and the vertical flow guide surface 12 has a circular arc tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com