Roadway tunneling construction method for coal mine overpass air bridge

A technology for overpass wind bridges and construction methods, which is applied in tunnels, tunnel linings, mining equipment, etc., can solve problems such as high cost, complex construction of concrete wind bridges, and large engineering quantities, and achieve simplified construction steps, stable support, and Avoid the effect of ventilation short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

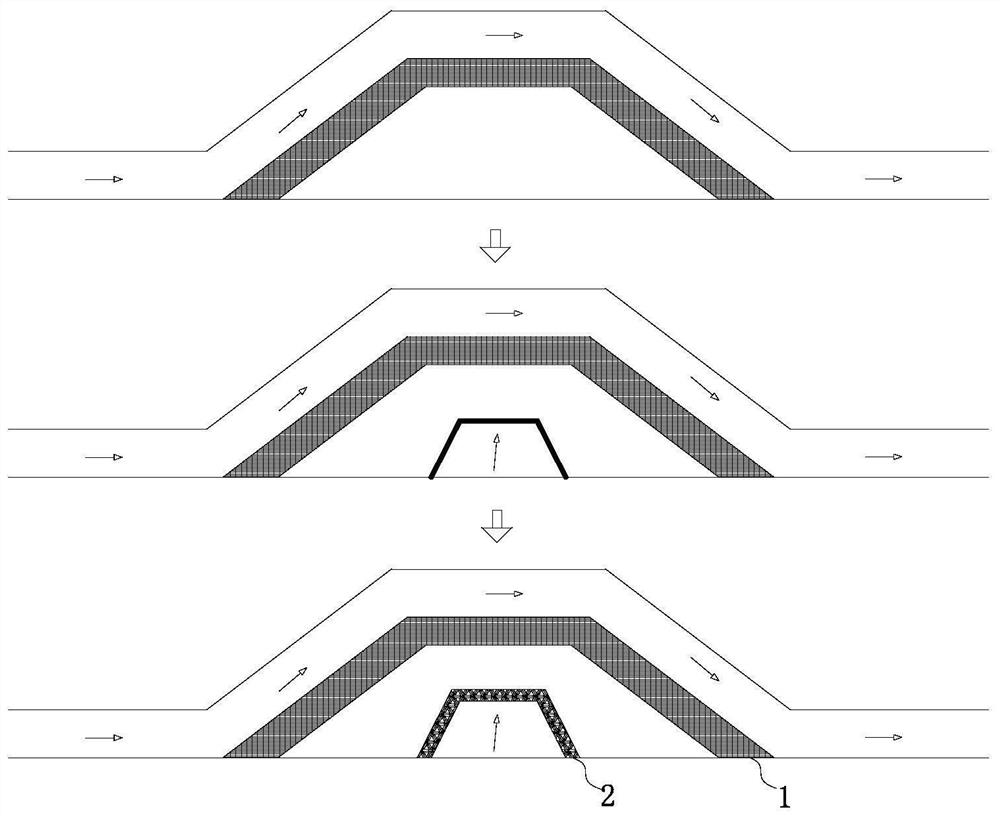

[0025] A coal mine overpass wind bridge roadway excavation construction method, which is applied to the overpass roadway construction at the intersection of the air inlet roadway and the return air roadway under the coal mine. The airtightness is ensured by constructing the false bottom of the upper roadway and the false roof of the lower roadway, so as to avoid the ventilation system caused by air leakage short circuit, the steps of the method include:

[0026] A. According to the position of the overpass calibrated by the mine ground survey data, the upper roadway at the position of the overpass wind bridge is the upper roadway, the lower roadway is the lower roadway, the upper roadway and the lower roadway are the air inlet roadway and the air return roadway respectively, and the upper roadway can pass through the upper roadway The slope alley and the downhill alley straddle the down alley. Excavate the foundation trench on the floor of the upper lane, where the size of the...

Embodiment 2

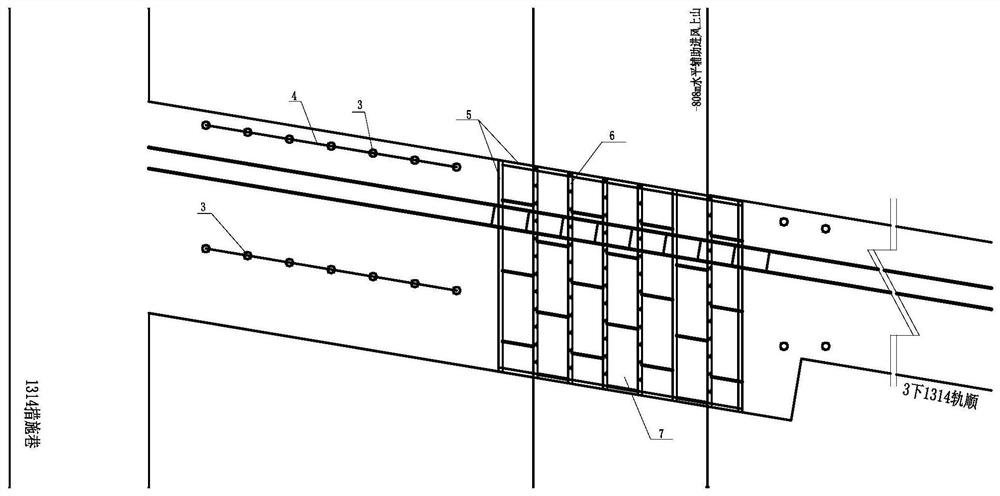

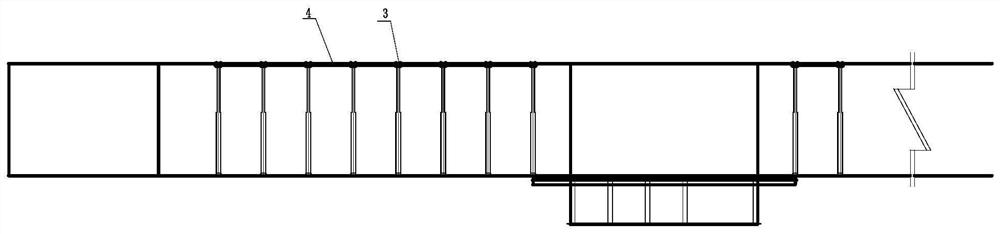

[0036] In combination with Example 1, the method will be further explained by taking -808 assisted wind uphill and 1314 track-shun interchange, -808 and filling connection lane interchange in a certain mine as examples.

[0037] -808 auxiliary air intake uphill and 1314 track-shun overpass, -808 and filling connection lane overpass, form overpass wind bridge when excavation roadway is penetrated, in order to prevent short circuit of air flow when overpass wind bridge is penetrated and ensure the stability and safety of the ventilation system and the roadway Support stability. During construction, the foundation groove of the construction false roof shall be calibrated at the site in advance, and concrete shall be poured into the foundation groove to form the false bottom of the upper lane (false roof of the lower lane). After all the overpasses have been passed head-on, start to build the false roof of the lower lane (lay steel plates above the I-beam shed beam). First, expand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com